Article by Sarah Do Couto and Angelica Pajkovic

Baker Hughes is one of the foremost industrial service companies in the world. Through the supply of oilfield services, products, technologies, and systems to the international oil and gas industry, the company has pioneered new technology and continues to inno-vate manufacturing processes.

Valve World had the great pleasure of speaking with Baker Hughes’ Nathan Brunell, Product Manager and Market-ing Executive, Brian Burkhart, Valve Lifecycle Management Leader of Digital Tech-nologies, and Kerry Nedic, Strategic Marketing Leader about the company’s unique approach to the innovation of its extensive product lines, its progression as an industry giant, and what the future holds for the company.

Progressive energy technology company

Since its establishment in 1907, 114 years ago, Baker Hughes has focused on oil field development, and recently has acquired top valve brands, Masoneilan and Consolidated, adding control and safety relief valves to help complete their equipment portfolio. Throughout the years, it has grown as a pro-gressive energy technology company, that has always looked at its business as a way of leading change in the industry. Its progres-sion from creating simple pressure relief valves to the establishment of its Valve Lifecycle Management (VLM) suite, is a testament to its commitment to directing these changes.

To accomplish this continual progres-sion, Burkhart explained that valves, like anything else, have to be recognized for having multiple stages in their lifecycle: birth, life, and obsolescence and upgrade. It is its devotion to providing customized attention to each stage, that makes both Baker Hughes, and its valves, continually sought after around the globe.

“Similar to the first stage of life of an actual valve, establishing firm standards and high-quality processes is vital to the integrity and longevity of the Baker Hughes valve businesses,” stated Brunell. “We, as a company, have a long history with a lot of firsts in the industry. These firsts include the creation and patenting of many valves and coefficients that paved the way for several technological and product developments over the last 100 years.”

Comprehensive solution provider

Today, Baker Hughes offers valves and services for several industrial sectors. Its diversity serves as a strongpoint to provide solutions for the various industry trends taking place around the world. “In order to ensure that we are able to grow in a number of areas we make sure to be aware of how trends are emerging differ-ently in various locations,” said Brunell. “By maintaining this wide collection of customers, regardless of industry, we are able to be a truly comprehensive solution provider.”

“It does not matter if you are in mining, chemical, petrochemical, pharmaceutical, or oil & gas,” added Burkhart, “process control and quality are the aspects, or problems, that every industry is looking to solve. We provide that solution”

The current aim of Baker Hughes is to aid its clients, regardless of industry,

in attaining success. For many of the company’s customers the overarching goal is the same; to keep the planet safe while achieving manufacturing outcomes through process control.

To do so, Baker Hughes is focused and dedicated to creating products and digital technologies that are brand agnostic, and capable of solving a myriad of different valve and system related issues. This means that the company aims to continu-ally create products that will function in tandem with any pre-existing technology already inside a facility, whether it be purchased from Baker Hughes or not. That is why the company has created products and systems like the Valve Lifecycle Man-agement Suite.

Baker Hughes Valves at a glance

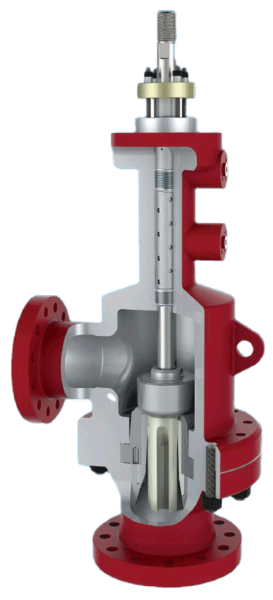

The Baker Hughes valves business has been operating since 1879 and has 11 valve manufacturing facilities across the globe that allow for in-region support and quicker delivery times. While it has a number of subsidiaries, it has two pri-mary valve businesses: Masoneilan™ and Consolidated™. Founded in the late 1800s, Masoneilan has a diverse range of control valve products commonly used for running global power stations, refineries generat-ing fuel, and food and beverage opera-tions creating vital products. Consolidated Pressure Relief and Safety Valves protect clients, plants, and people from any unex-pected overpressure events.

The company also has two secondary valve businesses; Becker, which produces natural gas pipeline products, and Mooney, which provides natural gas regulators to critical gas and heat operations.

The power of valve lifecycle management

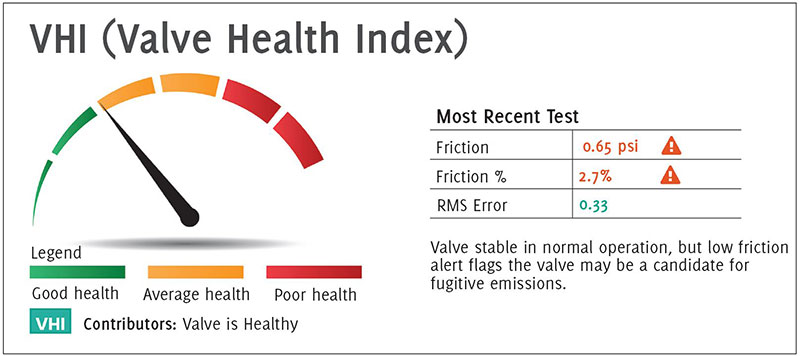

The Baker Hughes Valve Lifecycle Manage-ment Suite is a series of applications that aid a customer to manage their valves throughout their lifecycle: birth, life, and obsolescence and upgrade. Each of the ap-plications are compatible with a wide array of valve types, and brands, and consist of several unique industry-first features. While there are several applications avail-able in the suite, one of the key manage-ment products is the Masoneilan SVI3™ (or Smart Valve Interface) Digital Valve Positioner. This positioner sits atop pneu-matic control valves and delivers accurate, responsive, and reliable positioning performance data in a user-friendly manner. This device features 21 diagnostics to con-tinually monitor valve health and improve overall plant efficiency. The SVI3 differ-entiates with the ability to store up to one year of diagnostic data, providing the ability to trend performance over time and make data driven maintenance decisions. Control performance has improved with a 15% increase in air delivery for faster actuation, while air consumption has been reduced by 40%, supporting a significant reduction in compressed air costs and reducing overall plantwide emissions. Another integral service within the Baker Hughes Valve Lifecycle Management Suite is the valve health monitoring service ValvAware™. Through the utilization of past maintenance records and the continual monitoring of pneumatic control valves, this product identifies opportunity to improve plant integrity, efficiency, uptime, and profitability.

Not only about the end performance

“ValvAware is practical because it aggre-gates the positioner data all in one place and lets you see that from a remote loca-tion,” explained Burkhart. The application’s cloud-based capacities make ValvAware capable of diagnosing fluid leaks and control valve seating issues and alerting technicians as they occur. Functioning in tandem with the SVI series, Hart, or Foundation fieldbus positioners, ValvAware also diagnoses control valves, verifies proper installation and calibration, and conducts long-term performance trending with auto-mated data collection and analysis.

“We continue to develop our solutions around low emissions and the energy transition. We also continue to solidify our core markets because we feel like they are still going to be around for quite a while, and they need to have a top-quality supplier.”

“If you look at the theme of the new products that we have released in the past five to 10 years, it is not only about the end performance of the product, but rather, ensuring that we do not miss any pain points as we develop it,” said Burkhart. “To come to a solution like the SVI3, we assess potential issues, attempt to understand the pain points felt, and develop a product for the client in an economical way.”

“We want to meet the customer where they are and give them a solution that not only works for our own products, but works for the others as well,” stated Brunell. “You have your baseline – your foundation of core products – and then you build on those with technologies that optimize them. A diverse product portfolio is important from that perspective.”

Avoiding obsolescence through upgrade and innovation

Baker Hughes already has the future in its sightline. It knows that in order to contin-ue to thrive as a business, it must expand its network of customers, develop and pioneer new digital solutions, and lead the charge in the transition to green energy and manufacturing processes. “We are working to develop ourselves with more advanced solutions for delivery and supply chain fulfillment,” explained Brunell. In order to do this, he said that it is vital for Baker Hughes to remain in constant com-munication with their customers.

“One of the primary ways we stay on top of industry trends and innovations is our participation in different committees and governing bodies,” said Burkhart. “We have a heavy presence from our engi-neering group in committees like API and ASME.” It is here that Baker Hughes can liaise with end users and manufacturers to understand any technical issues and provide and advertise available solutions. “There are times where we have had some products and solutions that the end users and customers did not even know were possibilities,” said Burkhart. “To be able to collaborate in an environment like that is one way that we can understand what is going on in the industry.”

Unlocking future potential

Baker Hughes is also focusing on additive manufacturing (see box text Masoneilan 74000 Series) and digital technology solu-tions for the future, while also looking to lead the way for industry developments around low emissions and green technology. “We continue to develop our solutions around low emissions and the energy transition. We also continue to solidify our core markets because we feel like they are still going to be around for quite a while, and they need to have a top-quality supplier.”

As a company, Baker Hughes is dedicated to pioneering this transition to greener manufacturing processes, even when it may not be instantly beneficial. “I can see Baker Hughes’ willingness to invest in something that is not necessarily going to deliver profits right this minute, as an asset. We see this as a growing trend that customers and end users have, and then if we solve the problem today, that is go-ing to unlock a significant potential for the future,” said Burnell.

Continuous advancement and innova-tion are vital to the ongoing success of Baker Hughes. Through a focus on additive manufacturing and digital technologies, the lifecycle of the company and its prod-ucts can be maintained. The ultimate goal, explained Burnell, is as such: “We want to understand what the customer’s problem is, reach into our toolbox of solutions, and find the one that fits them best.”

Masoneilan 74000 Series

In coordination with the Baker Hughes additive technology lab, Masoneilan has devel-oped a proprietary additive metal layering technology delivered through a digital metal printing process that uses laser directed energy to fuse powdered metal tungsten carbide onto an Inconel substrate.

Masoneilan has used this technology innovation of its 74000 Series, Erosion Resistant Solutions, which the company launched in 2020. “Where the service conditions and eroding fluid of residual hydrocracking has quickly destroyed lesser designs, this solution surrounds the proven fluted trim design with an additive cladding that will measurably extend the service life of the product. Extensive lab validation has supported product release and field installations shipping from our Conde, France site in December 2020”, the company stated.

“The digital technology behind this solution is nothing less than game changing for our brand and our served industries”, comments Don Sanders, Masoneilan Sr. Product Manager. “Look for Masoneilan to deploy this technology on other tough applications, as we have both the commitment and the enabling know-how to lead the industry in this category. In the pursuit of truly differentiated products, additive manufacturing provides the platform to bring these solutions to market, giving our partner customers confidence to label their systems: Process Controlled!”

Source: https://valves.bakerhughes.com/news/masoneilan-74000-series-erosion-control-valve

About this Featured Story

This Featured Story is a cover story from our Valve World Magazine December 2021 issue. To read other featured stories and many more articles, subscribe to our print magazine.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”