By Robert McIlvaine

The Biden Administration has pledged to cut U.S. greenhouse gas emissions by 50 to 52 per cent from 2005 levels by 2030 and to zero by 2050. This is net CO2 emissions and not eliminating all sources. Consider that humans exhale CO2 and the goal is benefit to and not extinction of the human race.

China is planning on carbon neutrality by 2060. This may appear to be bad news for the valve industry. The switch from coal to wind and solar greatly reduces the opportunity for the valve industry. There is not just a little bit of irony in that a push all the way to carbon neutrality will actually result in the retention of coal fired plants only with a different fuel and different fate for the CO2. This in turn will substantially increase valve sales.

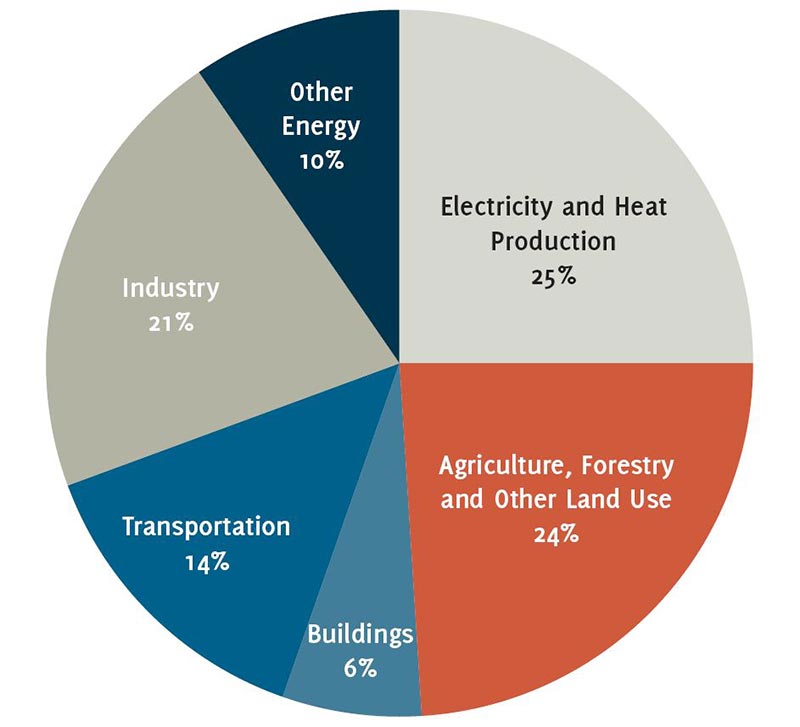

There are many sources of CO2 which cannot be eliminated. Coal-fired power accounts for only 14 per cent of the total CO2 emissions. Some of the industry, commercial, residential, and agricultural sources cannot be eliminated. Others such as eliminating meat from the diet will be difficult to achieve. It will therefore be necessary to utilize technologies which take the CO2 out of the atmo-sphere and sequester it in some manner.

CCS needed

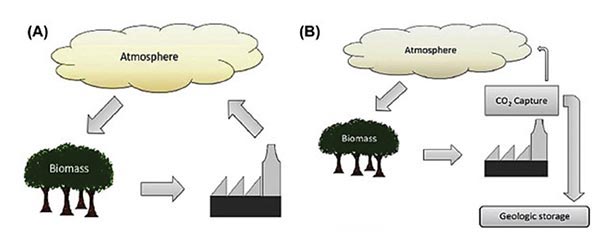

There is universal agreement that carbon capture and sequestration process will be needed to reach zero-carbon targets. However there are few choices. There is a direct air process with potassium chloride as an absorbent. This mode would mean lots of revenue for valve companies but it is too expensive for serious consideration. There is one option which is practical and is be-ing pursued by the UK, called Bioenergy Carbon Capture and Sequestration (BECCS).

For example, Drax operates a 4000 MW coal-fired power plant in the UK. It has purchased forests in the U.S. and transports wood chips to the plant. So it is already achieving carbon neutrality. The company is innovating on carbon capture and sequestration technologies and expects to be carbon negative on a progressing basis over the next 20 years. The cost of this approach is greatly reduced by the availability of existing coal-fired plants. Mini-mal capital investment is needed to switch to bio-mass. The problem is that if coal-fired plants are shut down, there won’t be any plants to convert. Global energy related CO2 emissions are 33 giga-tons (GT). Coal contributes 15 GT or 45 per cent of total energy production, which represents – as mentioned before – 14 per cent of total CO2 emissions. If all coal plants adopted BECCS, they would create a negative 15 GT of CO2 and offset emissions from other sources.

Conversion of coal plants

From this perspective, it is very important not to retire coal plants but to start converting them to BECCS. It is also important that those companies building new plants consider technologies which lend themselves to cost-effective conversion to biomass. To address climate change, Sumitomo has developed the so-called Flexi-Burn-technology, which allows circulating fluid bed boilers (CFBs) to operate in either conventional firing or carbon cap-ture mode without significant plant modification, giving clients the flexibility they need to endure an uncertain regulatory and carbon credit market. Detailed analyses were conducted relative to new coal plants in India. The ability to use lower-cost coal was one of the cost advantages. The conclu-sion was that the use of CFB was competitive for high quality coal sources and had advantages for low quality coal or biomass combustion.

Critical technology

There has been lots of publicity around the Chinese program in which inefficient coal plants are being retired and replaced by highly efficient low-emission, ultrasupercriti-cal coal-fired plants. China will curb coal consumption in its economic plans spanning the next 10 years, President Xi Jinping said April 22 at US President Joe Biden’s global climate summit. Xi also affirmed China’s existing targets on peak carbon dioxide emissions before 2030 and carbon neutrality before 2060. The Institute of Energy, Environment and Economy (Tsinghua University) has studied the options.

Their conclusion is as followed: “Bioenergy with BECCS is a critical technology that can offer net CO2-emission reductions while providing a sustainable energy supply at lower costs. The role of BECCS-deployment in achieving deep decarbonization in China needs to be quantified. Scenario analyses were conducted in this study based on a computable general equilibrium energy-economic model, the China-in-Global Energy Model (C-GEM), with detailed representa-tions of BECCS. The results showed that BECCS will capture 0.59 gigatons of CO2 in 2050 under the 2°C scenario and 0.95 gigatons of CO2 in 2050 under the 1.5°C scenario, respectively. If these emission targets have to be reached without BECCS, the carbon price and gross domestic product (GDP) losses will be higher. Especially under the 1.5°C scenario, the deployment of BECCS can reduce the carbon price by 61 per cent and the GDP loss rate by three percentage points in 2050 compared with that without the deployment of BECCS.”

Conversion highly likely option

With China’s commitment to carbon neutrality by 2060, the use and benefits of BECCS would be considerably greater than envisioned in the study. Carbon capture would be several gigatons of CO2. This BECCS-program will be of immediate benefit to the valve industry. Coal plants which would have been retired, will instead buy valves and pay for parts and services for existing valves. When the plants make the full conversion, there will large numbers of new valves needed.

There are a number of people in the valve and power industries who are aware of this situation. However, it is not clear that governments or environmentalists understand the options. Whether or not it was intentional, advocates of carbon neutrality are going to cause existing coal-fired plants to be converted to BECCS rather than retired.

(1) Industrial Valves: World Markets pub-lished by the McIlvaine Company

About the author

Robert McIlvaine is the CEO of the McIlvaithe McIlvaine Company which publishes Industrial VValves: World Markets. He was a pollution control ccompany executive prior to 1974 when he founded the present company. He oversees a staff of 30 people in the US and China.

Robert McIlvaine is the CEO of the McIlvaithe McIlvaine Company which publishes Industrial VValves: World Markets. He was a pollution control ccompany executive prior to 1974 when he founded the present company. He oversees a staff of 30 people in the US and China.

About this Featured Story

This Featured Story is an article from our Valve World Magazine September 2021 issue. To read other featured stories and many more articles, subscribe to our print magazine.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”