GD Energy Products (GDEP), the total solutions provider for the frac, drilling, and well servicing market, has proven in field trials that its new Redline+ Valves and Seats significantly increase performance life in high pressure hydraulic fracturing operations.

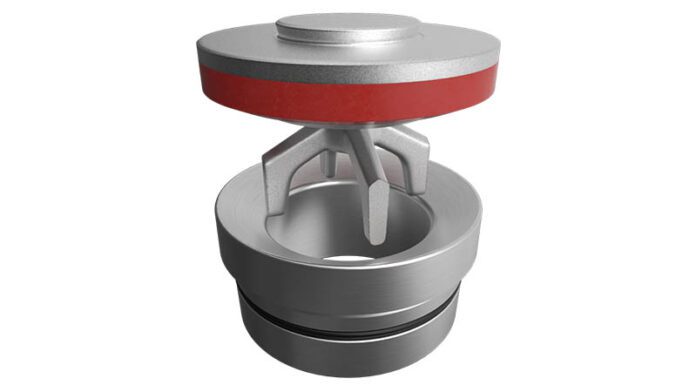

In line with GDEP’s commitment to continuous innovation, Redline+ Valves and Seats are the latest addition to GDEP’s Redline Series Consumables. The new valves and seats feature a patent-pending design and optimized metallurgy resulting in enhanced wear resistance and strength. Compatible with both GDEP and competitor fluid ends, the Redline+ designs have significantly increased resistance against chemical abrasion.

Manufactured in the USA, GDEP’s Redline+ Valves and Seats have been tested in numerous basins outperforming the competition with supreme performance and reliability. Operating under harsh environments, the valves and seats demonstrated consistent performance, fewer maintenance intervals, and longer life.

During a one-month trial in the Permian Basin, the new valves and seats showed a 37% increase in the number of strokes between valve changes when compared to the competition. The new technology enabled customers to extend maintenance intervals, which reduced total consumable consumption by 20%.

In the Haynesville Basin, notorious for its ultra-high pressures and extremely harsh conditions, Redline+ Valves and Seats presented a 25% increase in the number of stages, when compared to GDEP’s V3 valve. The new line showed consistent field performance that improved uptime and led to less unscheduled maintenance.