IMI Critical Engineering has further enhanced its additive manufacturing capacity with the installation of a new 3D printing machine at its South Korea facility.

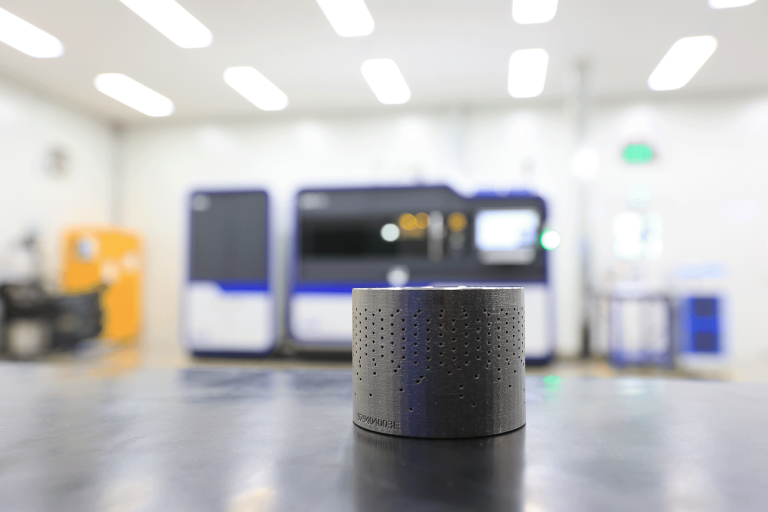

The premises, based in Paju City, Gyeonggi Province, took delivery of an SLM280 PS printer in December 2022 to expand its capacity to include the production of 3D-printed parts. The printer, which was integrated into production in February 2023, following an internal qualification process, is now used to manufacture control valve components such as IMI Critical Engineering’s own patented DRAG® technology disk stack and seat baskets.

The expansion of its in-house 3D capabilities will also enable IMI Critical Engineering Korea to offer additional, advanced engineering solutions available to both local and overseas markets. Specifically, the printer will enhance the benefits of the existing Retrofit3D solution, and allow operators to respond quickly with custom engineered solutions designed around customers’ operating conditions.