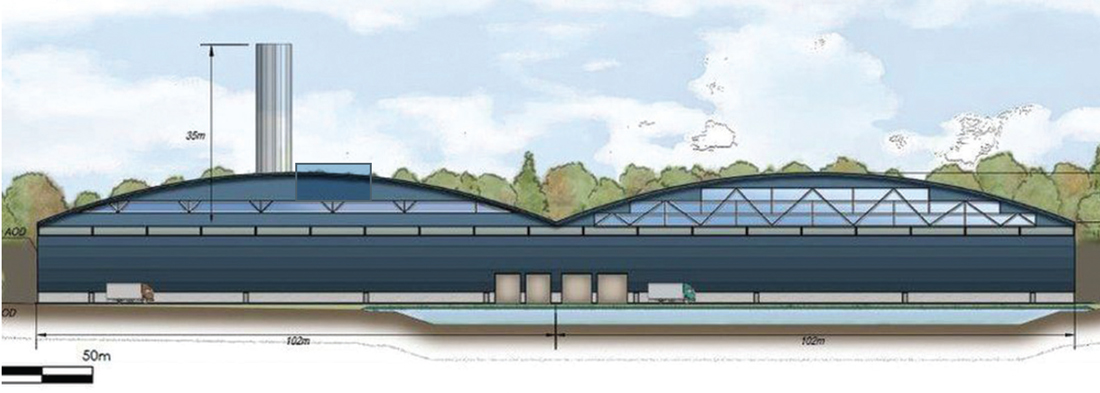

Indaver plans to build a 595,000-tonnes-a-year waste-to-energy (wte) facility in Rivenhall, Essex (UK). The proposed Integrated Waste Management Facility (IWMF) will be the company’s first wte-facility in the UK and will generate approximately 49MW of electricity for export to the national grid to supply the power needs of approximately 60,000 households.

By Lucien Joppen

Waste-to-energy is an established method to turn household and similar waste that could not be prevented or recycled into energy (heat and/or electricity). This energy can be generated in various forms, such as steam, electricity or hot water.

The electricity is fed into the grid and distributed to the end-users. Hot water, depending on local infrastructure, can be sent to a nearby district heating (or cooling) network to heat (or cool) homes, hospitals, offices et cetera. Steam can be used by the nearby industry in their production processes.

Waste-to-energy has been developed to reduce landfilling which is considered not to be most sustainable solution for waste that can not be recycled. Ideally, waste-to-energy should be combined with recycling facilities for waste streams that are too valuable to be incinerated. These facilities are called Integrated Waste Management Facilities of which Rivenhall will be a prime example.

Additionally, wte-plants also contribute to cli-mate protection and security of energy supply by replacing fossil fuels that would have been used to produce this energy in conventional power plants.

Processing lines

At these facilities, household and similar waste are sorted at the source by which clean materials (such as metals) are sent to high-quality recycling. The remaining waste, that cannot be recycled in a technically or economically viable way, is used to generate energy.

As for Rivenhall, the facility would include various processing lines. One line would be for producing Incinerator Bottom Ash Aggregate (IBAA). Incinerator Bottom Ash (IBA) is produced by wte-plants and is composed of the inert, non-combustible fraction of the waste processed through the plant. Before the IBA is used on site (for example for road construc-tion) it has been processed to remove metals and graded into different fractions that can be blended with virgin aggregate for various uses. IBAA is said to be a sustainable alternative to the quarrying of virgin aggregate and makes use of waste that would otherwise go to landfill, turning it instead into a valuable resource.

Change of plan

Apart from producing IBAA, the Rivenhall IWMF would also comprise a de-inking and paper pulping facility, an anaerobic digestion (AD) plant, a material recycling facility (MRF), and a mechanical biological treatment (MBT) facility.

According to Indaver, the paper pulping facility would not be economically viable.

The decision to drop this facility, however, has not fallen well with the county council of Essex which has allocated the planning permission to build the facility provided all processing facilities would be in place, including the paper and pulping facility. According to the Essex county council, every element of the Rivenhall project must be built and ready for “beneficial use” by the end of 2026.

It remains to be seen how this will play out. For the time being, local government is adamant that the facility will be built as described in Indaver’s initial proposal.

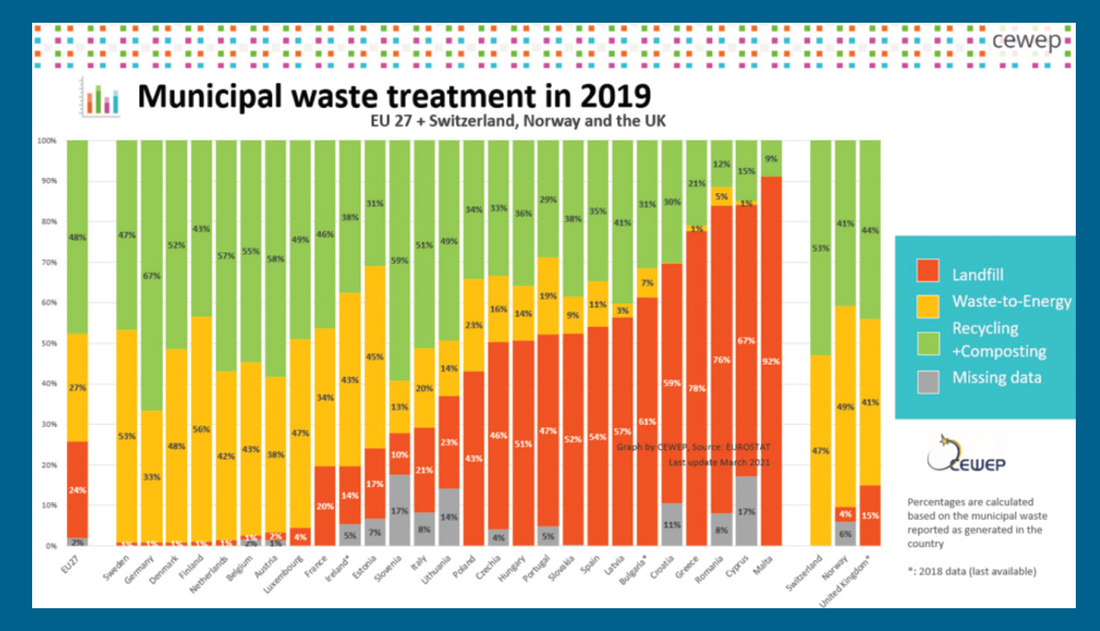

Each year after publication of the Eurostat-figures for Municipal Waste Treatment, CEWEP produces many graphs based on this data to show the state of waste treatment in Europe. The graph below shows the share of recycling (including composting), waste-to-energy and landfilling of municipal waste in each EU Member State (plus Norway, Switzerland and the United Kingdom).

In terms of waste-to-energy, Scandinavia, Finland, the Netherlands, Belgium and Austria are far ahead of the rest of the EU. Other countries clearly need to reduce their landfilling, given the EU’s aim to reduce this practice. The EU Landfill Directive from 1999 aims “to prevent or reduce as far as possible negative effects on the environ-ment, in particular the pollution of surface water, groundwater, soil and air, and on the global environment, including the greenhouse effect, as well as any resulting risk to human health, from the landfilling of waste, during the whole life-cycle of the landfill”.

First phase completed

Indaver has appointed global greentech company Hitachi Zosen Inova (HZI) as its EPC contractor for the ‘Rivenhall Integrated Waste Management Facility (IWMF) and Energy Centre’. The EPC contract has been signed and Notice to Proceed is effective on May 9 2022.

HZI has already been preparing the con-tract with Indaver for the Rivenhall project for over 12 months, the company states. HZI will be responsible for building the Energy from Waste (EfW) element of the IWMF and Energy Centre, working alongside civil contractor PJ Hegarty Limited and earth moving contractor Tom Blackwell Limited.

The first phase of construction which began in March 2021 is completed, as three million tonnes of soil has already been excavated from the site. This has created the space for the other contracts to now begin.

The Energy from Waste part of the facility is on track to begin commercial operations in Q1 2026, with a capacity of 595,000 tonnes per annum (49.9Mwe). The total permitted capacity of the IWMF is 853,000 tonnes per annum including other waste management activities.

About this Featured Story

This Featured Story is an article from our Valve World Magazine July 2022 issue. To read other featured stories and many more articles, subscribe to our print magazine.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”