Foster Voelker discusses the implications of the EPA’s new rule on emissions regulations in the oil and natural gas sector, focusing on its impact on the valve industry and the development of low-emission technologies.

By Foster Voelker II, Director of Engineering – Williams Valves

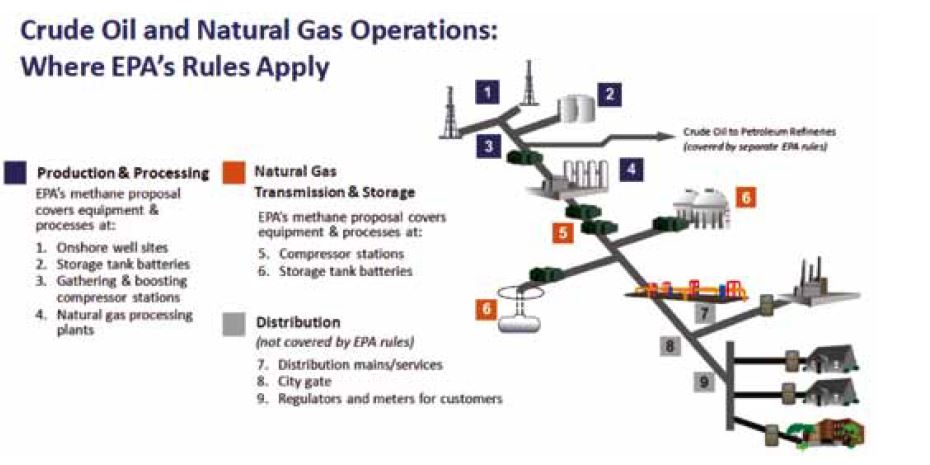

In response to President Joe Biden’s Executive Order, the Environmental Protection Agency (EPA) proposed a rule in 2021 to revise emissions regulations in the oil and natural gas sector, aiming to reduce methane and volatile organic compound (VOC) emissions by reassessing the New Source Performance Standards (NSPS) and proposing new regulations for both new and existing operations.¹

EPA releases new requirements

The EPA’s final rule, released on December 2, 2023, focuses on significantly reducing methane emissions, VOCs, and hazardous air pollutants (HAPs) from U.S. oil and natural gas operations. The rule updates standards for new, modified, and reconstructed sources, and provides guidelines for existing sources, incorporating the NSPS and Emission Guidelines (EG). Key measures include phasing out routine flaring, mandating regular leak monitoring, and encouraging the use of innovative technologies. The EPA estimates that this rule will prevent 58 million tons of methane emissions from 2024 to 2038, in addition to substantial reductions in VOCs and toxic air pollutants. The rule reflects comprehensive industry and public input, offering flexible yet rigorous standards for emissions control.²

Overview of new rule

The final NSPS OOOOb and EG OOOOc standards are expected to significantly reduce emissions in the oil and gas sector. Between 2024 and 2038, these standards aim to cut approximately 58 million tons of methane emissions (equivalent to around 1.5 billion tons of CO2), 16 million tons of VOC emissions, and 590 thousand tons of HAP emissions. While the estimated average annual regulatory compliance cost over the 2024-2038 period is approximately $1.5 billion, related to the implementation and maintenance of required emissions control technologies, the EPA contends that these costs are offset by the environmental and health benefits of reduced emissions.

Equipment requirements include:

- Zero-emitting controllers: The rule mandates the use of zero-emitting controllers for specific equipment, indicating a shift towards more environmentally friendly technologies.

- Open-ended valves or lines: These must be equipped with a closure device to prevent unintended emissions.

- Monitoring and control devices: Regular monitoring of CVS using Optical Gas Imaging (OGI) or EPA Method 21 is required to minimize emissions.

- Pressure relief devices: These devices must be monitored within 5 days after a pressure release to ensure proper functioning.

- Definition of repaired equipment: The rule specifies that repaired equipment must be adjusted or replaced to eliminate leaks and re-monitored to verify emission reduction.

- Use of Low-E equipment: Repairs may include the use of Low-E valves or materials, but complete replacement with low-E equipment is not mandated, allowing flexibility in repair methods.

- Specifications and guarantees of Low-E equipment: Low-E equipment must meet API 622 or API 624 standards and typically includes a manufacturer’s warranty or performance guarantee.

The NSPS OOOOb and EG OOOOc standards target a 79 percent reduction in methane emissions from covered sources between 2024 and 2038. This significant reduction is expected to yield substantial climate, environmental, and health benefits, marking a major advancement in mitigating emissions from a key U.S. industrial methane source.

Impacts on the valve industry

The impact of the new EPA rule on the valve industry is substantial, particularly in the context of reducing emissions. Valves are critical components in the control and management of gas flow, and the new regulations necessitate significant changes. This includes the development and implementation of low-emission (Low-E) valves and materials. The requirements for Low-E technology in the context of the EPA’s new rule are focused on:

- Use of Low-E technology for repairs: When a leak is detected in a valve, the operator must either repack the existing valve with low-E packing, replace it with a low-E valve, or perform a drill-and-tap repair using low-E injectable packing. The rule allows exemptions if technically infeasible. Operators are not required to use low-E valves or packing if they can demonstrate that it is not technically feasible. Considerations for deeming a low-E solution technically infeasible include cases where the low-E technology is unsuitable for the valve’s intended use, retrofit requirements (like re-piping or space limitations), commercial unavailability for specific types of valves, or issues with certain instrumentation assemblies. Operators must annually report instances where it was infeasible to use low-E technology for repairs, including the reasons for infeasibility.

- Definition of Low-E valves and packing: Low-emission (low-E) valves and packing are defined as follows: A low-E valve is a type ofvalve for which the manufacturer provides a guarantee that it will emit fugitive emissions at a rate of less than 100 parts per million by volume (ppmv) over the first five years. Similarly, low-E packing, used in these valves, adheres to the same emissions standard as per the manufacturer’s warranty. Additionally, there is low-E injectable packing, which is specifically designed for drill-and-tap valve repairs and also comes with a manufacturer’s guarantee regarding emission levels. The EPA outlines that low-E equipment meets the specifications of API 622 or API 624 and typically includes a manufacturer-written warranty or a performance guarantee that it will not emit fugitive emissions at a concentration greater than 100 ppmv during the first 5 years.

Another area of significant impact is pneumatic controllers. According to the EPA, “Pneumatic controllers are process control automation devices used widely in the natural gas industry to operate valves that control liquid level, pressure, and other process variables. While they can be powered by natural gas or compressed air, natural gas-powered pneumatic controllers are commonly used. Some pneumatic controllers are designed to bleed (or emit) continuously, while others may emit natural gas into the air only when actuated or malfunctioning. Pneumatic controllers are one of the largest sources of vented methane emissions from the natural gas industry.³”

The new EPA rules regarding controllers, specifically natural gas-driven process controllers, are designed to significantly reduce emissions, particularly methane, from these devices in the oil and gas sector. The key rules for controllers include:

- Zero emissions standard: For sites outside of Alaska, all process controllers are required to achieve zero emissions of volatile organic compounds (VOCs) and greenhouse gases (GHGs), specifically methane. This standard applies to both new and existing sites. Compliance can be attained through several methods: utilizing process controllers that are not driven by natural gas, thus not being classified as affected facilities; routing vapors from natural gas-driven process controllers through a closed vent system to a process where they can be controlled; or using self-contained natural gas-driven process controllers, among other methods, to ensure the numerical standard of zero emissions for methane and VOCs is achieved.

- Special provisions for emergency shutdown devices: Process controllers that are used as emergency shutdown devices (ESDs) or are not natural gas-driven are not included under the affected facility category in these standards.

- Bleed rate requirements: For certain types of process controllers, such as continuous bleed controllers, there may be specific bleed rate requirements. For instance, these controllers might be required to have an emissions rate (or bleed rate) of less than or equal to 6 standard cubic feet per hour (scfh).

In conclusion, the final rule set by the EPA marks a critical step towards mitigating the impact of the oil and gas industry on the environment and public health. By targeting equipment emissions, the rule addresses one of the key sources of air pollutants in this sector. The anticipated reduction in methane, VOC, and HAP emissions over the next 15 years underlines the rule’s potential to contribute significantly to cleaner air and a healthier environment. Moreover, the inclusion of advanced detection technologies and the focus on energy-efficient emissions control highlight the rule’s approach to balancing environmental goals with economic considerations. The 79 percent projected reduction in methane emissions underscores the rule’s potential for significant climate benefits.

About the author

Foster Voelker II attended the University of Houston, receiving a degree in Mechanical Engineering. After graduation, Foster Voelker began his career as a valve engineer for a large commodity valve manufacturer. He is the Director of Engineering for William E. Williams Valve Corporation.

Foster Voelker II attended the University of Houston, receiving a degree in Mechanical Engineering. After graduation, Foster Voelker began his career as a valve engineer for a large commodity valve manufacturer. He is the Director of Engineering for William E. Williams Valve Corporation.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, June 2024 issue. To read other featured stories and many more articles, subscribe to our magazine.