A new series of high strength austenitic stainless steels has been developed specifically for cast products, offering improved properties over traditional options like 6Mo grades.

Philip Roscoe, N’GENIUS Materials Technology

Design flexibility, quick turnaround times and cost-efficiency are among the many reasons why stainless steel castings are an important component in high quality valve manufacturing.

The casting process allows for materials to be moulded into detailed, complex shapes and sizes in a relatively short timeframe. And because of the reduced labour and lead times required compared to forging, the cost-effectiveness of producing cast components for valves can be a big advantage during both the specification process and the manufacturing stage.

With European-based stainless steel producers facing added pressures of high energy costs and low margins due to market prices set in other regions of the world, it is a highly competitive industry for the manufacturers. Fortunately, the future looks promising for the stainless steel casting industry with annual growth of more than 4% expected until at least 2032, particularly for large components.

Applications in the aerospace, energy and automotive sectors are driving the demand for stainless steel cast products including cast valve bodies and with governments committing to increased spending in the defence industry, it is a market poised for expansion.

With these industries and others prioritising a shift towards advanced materials which are more durable and sustainable, investment in R&D and innovation is fast becoming an important strategy for manufacturers. However, alloy development in stainless steels is not traditionally associated with the castings industry.

A cast material is a different animal

The vast majority of austenitic grades – which represent between 65% to 70% of all stainless steels manufactured globally – were initially designed for wrought products and then adapted for castings. But the manufacturing processes involved in the two product forms are very different, as is the mechanical properties and performance of the materials produced.

Cast alloys possess lower strength properties and sometimes different corrosion resistance levels compared to their wrought counterparts despite having the same or a very similar chemical composition. Furthermore, some of the higher alloyed wrought grades are notoriously difficult to cast and are susceptible to defects as cast materials.

Two of the well-known ‘superaustenitic’ stainless steels – S31254 and N08367 – were developed as wrought materials in the 1980s and utilised for piping in seawater environments in the oil and gas industry. Equivalent cast versions of these alloys were then developed as valves and pumps were required. These are known as CK3MCuN and CN3MN respectively but the materials are more commonly referred to as ‘6Mo’ grades as they contain at least 6% molybdenum.

The cast versions of these grades tend to be problematic, partly because there is often no secondary argon oxygen decarburisation (AOD) stage in foundries unlike large stainless steel mills which manufacture wrought products. These materials are difficult to cast in thick sections, they are prone to hot cracking, macro-segregation, micro-segregation and secondary phase precipitation. Equally, they can also experience grain growth during solution heat treatment.

There is another issue regarding the mechanical properties. Both the minimum yield and tensile strength of cast 6Mo grades are significantly lower than in the wrought versions, restricting their suitability for applications involving high pressure and the design parameters in terms of system weight.

Bucking the trend

The initial success of superduplex stainless steels was partly due to the demand for better cast materials which could compete with 6Mo grades on corrosion resistance but also possessed higher strength properties, enabling savings for piping systems in terms of weight, size and cost. The original 25Cr superduplex – which became the stainless steel cast grade 6A – was invented around the same time as 6Mo but as a cast material for pumps and valves. Its sudden popularity then created the need for a wrought version for pipes, fittings and flanges.

It is a unique example of an alloy developed specifically for improved castability and in-service performance in cast products as opposed to simply modifying materials that were designed for another purpose entirely. The metallurgist behind the superduplex invention has since adopted this same principle more than 40 years later – although this time for a whole family of grades.

Breaking new ground

Dr Ces Roscoe, who pioneered the first superduplex grade whilst at pump manufacturer Mather + Platt in 1983, has invented and patented an entire series of high strength austenitic stainless steels tailored for cast product forms as well as wrought. Grades in the N’GENIUS Series possess all the typical benefits of conventional austenitic stainless steels including excellent ductility and toughness at ambient, sub-zero and cryogenic temperatures. But with vastly superior strength and corrosion resistance.

It provides engineers with an extensive choice of high-performance, high strength austenitic stainless steels including some materials which are cost-effective alternatives to certain nickel alloys.

Dr Roscoe, CEO of N’GENIUS Materials Technology, said: “The 6Mo grades and superduplex have been well utilised over many decades and will continue to be in the future. But like with any material, there is a limit to their technical capabilities.”

“The industries they were originally intended for use in such as the oil and gas sector now often require piping systems with better corrosion resistance beyond the normal range for these grades.”

“Examples of this are sour gas developments in Middle East countries including Qatar, Saudi Arabia and UAE which can contain high levels of CO2, H2S and chlorides.”

“6Mo also lacks the mechanical strength properties required for high pressure service. So there is clearly a need for more high-performance stainless steels that have these features and some of the N’GENIUS high strength austenitic grades are the perfect solution.”

A world first in castings

Stainless steel manufacturers have already started noticing this trend. It’s one of the reasons why British steel foundry Furniss & White became the first company in the world to manufacture castings in the N’GENIUS Series.

The Sheffield-based firm, which serves the valve, pump, filter and engineering industries with high integrity castings from approximately 0.5kg to 2,600kg finished weight in a range of materials including carbon and low alloy steels, stainless steels and nickel alloys, is now producing castings for engineering products using various N’GENIUS grades under license.

Sam Scholes, Managing Director at Furniss & White, said: “We have had enquiries from customers wanting stainless steels that contain higher nitrogen and have improved castability. It is great to be able to offer them exactly that with N’GENIUS.”

“Some of these grades completely outperform 6Mo on strength and corrosion resistance, which is very exciting from a manufacturing perspective.”

“We expect them to be extremely popular with our existing customers and help open up new opportunities in other markets such as the US and Canada.” Among the company’s cast offerings, Furniss & White manufactures components for a range of valve types including globe, control, choke, ball, butterfly and through conduit gate valves. These can now be provided in various grades of the N’GENIUS Series, with one alloy in particular proving to be an ideal cast alternative to 6Mo alloys.

The new challenger to cast 6Mo

Containing less molybdenum and a higher level of nitrogen than 6Mo, the chemical composition of N’GENIUS 326L35M4N has been carefully selected to optimise castability and performance. The result is an alloy that possesses significantly higher mechanical strength properties and far superior resistance to pitting and crevice corrosion.

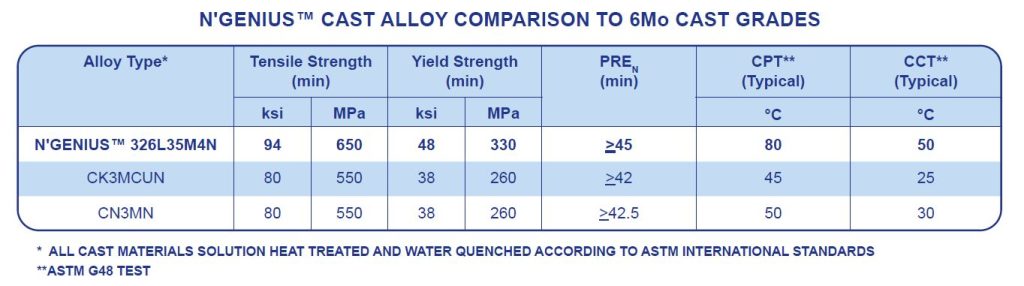

The strength properties, pitting resistance equivalent number (PREN), critical pitting temperature (CPT) and critical crevice temperature (CCT) of N’GENIUS 326L35M4N is shown in the Table, along with that of CK3MCuN and CN3MN for comparison.

As with all grades from the N’GENIUS Series, 326L35M4N can be manufactured in a vast array of cast and wrought product forms allowing all the various components of piping systems including valves, pumps, filters, pipes, fittings and flanges to be specified in the same material.

Compared to 6Mo grades, the improved mechanical properties of N’GENIUS 326L35M4N will allow some of these products to be designed with a reduced wall thickness, giving engineers the opportunity to make significant weight savings on piping system projects. Alternatively, for those components in which wall thickness is difficult to reduce – including cast valve bodies – these can simply be designed with a higher degree of safety.

Weight savings are particularly important for subsea and offshore structures where piping systems tend to be heavy and difficult to handle. By utilising products manufactured in N’GENIUS 326L35M4N these structures could become lighter, making the installation and construction easier and reducing project costs. Valves are fundamental to any piping system and choosing the right material for these components gives the best chance of it being a safe, durable and easy to maintain structure. With the availability of N’GENIUS, those prospects have now improved even further.

About the author

A former broadcast journalist, Philip Roscoe is Communications officer at N’GENIUS Materials Technology. The UK-based company specialises in the invention of next-generation stainless steels.

A former broadcast journalist, Philip Roscoe is Communications officer at N’GENIUS Materials Technology. The UK-based company specialises in the invention of next-generation stainless steels.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, September 2024 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Technical Story on Valve World online and in print.”