A technology integrating sensors, engineered safety controls and best practices to remotely operate accumulator valves down-well has been awarded.

By Joanne McIntyre, Editorial Manager Valve World

Intelligent Wellhead Systems Inc. (IWS), a supplier of digital technologies that im-prove oil and gas well completion opera-tions, has received a Special Meritorious Award for Engineering Innovation (MEA) in the Digitalization category from Hart Energy for its inVision® Digital Valve Control™ technology. The technology was one of only 22 selected this year by Hart Energy for its special signifi-cance to the future of the upstream petroleum industry.

Improving wellsite safety

“I find it very inspiring that our inVision technology has been honoured as one of the industry’s game-changing innovations of 2022,” said William Standifird, CEO of IWS. “From the beginning, the IWS team set its sights on opti-mizing completions performance and wellsite safety by developing technologies that help to achieve these goals. To have our efforts recog-nized by Hart Energy is certainly a fitting way to demonstrate our commitment to improving HSE performance at the frac site, as well as enhancing efficiencies,” he added.

Mitigating risk

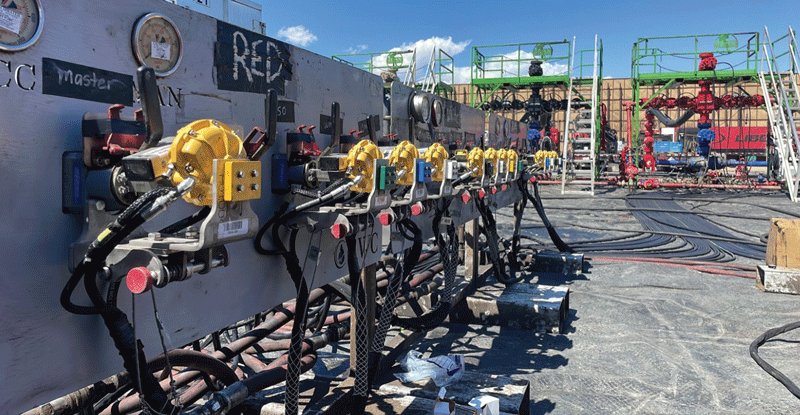

According to Hart Energy, inVision Digital Valve Control technology helps mitigate the risk and improve the efficiency of hydraulic fracturing, wireline and pressure control operations. The technology integrates a wide variety of sensors, engineered safety controls and best practices to remotely operate accumulator valves using digitally enhanced standard operating procedures. With this approach to remotely operating accumulator valves, it is possible to open or close access multiple wells to increase efficiency while reducing the risk of human error that can cause catastrophic failures that lead to loss of life, injury and equipment damage.

Over 50,000 incident-free stages

The technology platform has helped achieve over 50,000 incident-free stages on 1,000 completions in Canada and the US. The latest innovation to the platform, inVision Digital Valve Control technology, was introduced in February 2022 and implemented by Aethon Energy in its Haynesville wells. The new technology has continued to achieve a zero-incident performance track record with Aethon, experiencing zero cut wirelines, zero well shut-ins, zero pressure control incidents and zero injuries to date. Wellsite personnel no longer need to manually open or close accumulator valves. Frac, wireline, pressure control and Aethon stakeholders can now visualise wellhead valve status and control valve readiness for frac fluids or wireline tools going into – and out of – the well on handheld inVision SIMOPS tablets. Safety situational awareness of operations is improved, and continuous improvements in well swap and pumping times can now be enabled. The technology is helping demonstrate that digital technologies play a vital role in reducing risk in hazardous operations because humans cannot be situationally aware 100% of the time.