The IOGP JIP33 program has been a great success in the short time it has been active, and is now actively engaging with operators and EPCs to further adoption across the industry.

By Adri Postema, Engineering and Standards Director & JIP33 Programme Director IOGP; and David Harris, Specifications Manager JIP33, IOGP

The basic premise for JIP33 procurement specifications is to have standardised technical, quality and information requirements that overlay a recognised industry standard (Figure 1). JIP33 specifications also have a standardised Data Sheet for each specification that should increase efficiency and help simplify communication between purchaser and supplier regarding requirements and product configuration.

Case studies performed by equipment suppliers on behalf of JIP33 have shown that standardisation of quality and information requirements is as impactful on cost and schedule for the manufacturer as are the technical requirements. Of the 54 JIP33 specifications published, 24 have API as a parent standard, 8 have IEC as a parent, 9 have no parent standard, and the remaining are to various other Standards Development Organizations.

The content of IOGP specifications will be offered for consideration to be included in the underlying parent standards once these get updated. This reduces the overall maintenance activity of JIP33 specification and ensures wider use of the JIP33-specific requirements. Since 2019 JIP33 has included the digital aspects of specification development and publication (see article in Valve World, March 2023). Developing specifications as digital data files, using digital requirement management tools, provides an opportunity for quick feedback loops for users of the JIP33 specifications.

Changing the future of specifications

Both the move to authoring specifications to a defined set of digital rules, as well as publishing the specifications so they can be incorporated into a company’s business system, is a journey that Standards Development Organisations (SDO) are all embarking on. The IOGP has had a Task Force looking at standardising Requirements for Digitization since 2018 and JIP33 is an early adopter sharing experiences in digital specification writing and using digital exports of the JIP33 specifications for importing into a company’s established systems. JIP33 are actively sharing the best practices with the SDOs with the aim that there will be a common set of rules for digital requirements in the future.

This digitisation, as well as the cultural and behavioural mindset that standardised procurement specifications needs, requires strategic management of change within organisations. Subject Matter Experts and engineers have the opportunity to think and work in a significantly more efficient way than how the industry has traditionally operated for decades. Given the fact that the twelve sponsoring operating companies who are actively participating in JIP33 development have their own business, organisational systems and cultural differences, getting them all to move in the same direction and compromise their traditional practices has been a transformational change for the industry.

Within the 12 JIP33 sponsoring companies, there has been strong leadership from the top, setting a consistent set of expectations of ‘using JIP33 specification without change’ throughout an organisation. Successful JIP33 implementation is beyond engineering, and requires involvement from the company’s supply chain organisation and adaptation from information and quality functions. Managing these expectations has been best shown by introducing Key Performance Indicators (KPI) through the organisational structure that align with the company’s overall strategy and objectives. This helps drive the engagement and cultural change needed. As the JIP33 program has developed, the KPIs used by the sponsoring companies have also developed, and they are now looking at pushing the KPIs further into the supply chain.

Supply chain & stakeholders

The oil & gas supply chain for capital projects is complex, as it tends not to have a direct purchase-supplier structure. Instead, requirements go from an owner/operator to an EPC, then a packager and finally to manufacturers (and sometimes their sub-suppliers).

This means that recognising and maintaining the integrity of a JIP33 specification through the supply chain is not simple, especially when requirements are imported into a company’s business system. This can make gathering KPIs on how JIP33 implementation is evolving both internally and externally complex. Setting up expectations and systems to collect the necessary data for KPIs should be done at the beginning of a company’s implementation journey. This should extend to company expectations on gathering relevant data from their supply chain.

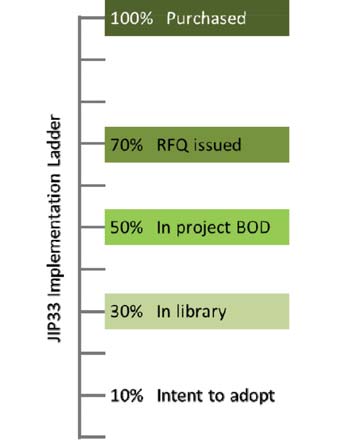

Initial KPIs for JIP33 sponsoring operating companies’ focus were leading in nature and focused on the level of implementation of specifications within the owner/operators, from the adoption of the specification through to purchasing (Figure 2).

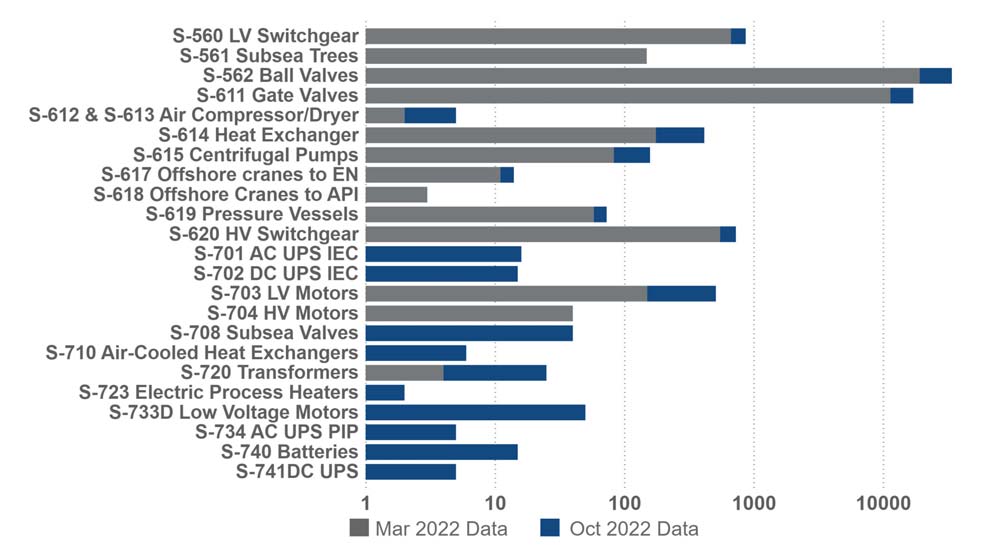

Now that implementation is maturing in most of the sponsoring operating companies, the program is looking to establish more result-focused KPIs on the volume of equipment purchased (Figure 3), projects utilising JIP33 specifications, and the percentage of value captured. The sponsoring operating companies are now asking their EPC partners to track and monitor comparable data within those organisations to demonstrate how JIP33 specifications adoption is expanding.

The KPIs are intended to show JIP33 adoption throughout the supply chain, but it is also possible to monitor the value derived from JIP33 implementation. Due to supply chain complexity, market fluctuations and oil price, baselining cost and demonstrating the cost impact of JIP33 can be challenging. However, what can be determined are the engineering hours required to issue a Request for Quotation (RFQs) for a standardised product, as well as tracking the reduction in clarifications that result in issuing standardised requirements. For manufacturers, having standardised requirements and Data Sheets means there should be less administration needed in responding to RFQs.

Over the years, JIP33 has organised industry events to discuss the initiatives with key supply chain stakeholders. Recent engagement activities include inviting senior management from regional suppliers, EPCs and non-sponsoring Operating Companies to the IOGP Engineering Leadership Council to discuss their real-world experience with JIP33 to date and to discuss recommendations on driving adoption further. JIP33 has a communication plan for more in-person events and webinars, and will continue this outreach throughout the coming years.

Implementation guides and training videos have been developed to help companies better understand the JIP33 process and how best to implement the specifications. Increased engagement with supplier partners has improved the overall JIP33 development process and the quality of the specifications. Initially, supplier input was limited to the draft specification public review. That has now evolved significantly, and there is more opportunity for suppliers, EPCs and non-sponsoring companies to actively contribute to the JIP33 process.

Supplier questionnaires and user feedback reviews on current specifications are being used as input to the process. In addition, there are public reviews of draft specifications and post-review town halls to provide feedback to commenters on the changes made to the document. For certain specifications, suppliers even actively participate in shaping the draft specification where anti-competition rules allow.

Lessons learned

Besides needing strategic management of change and associated KPIs to monitor adoption, some other fundamental principles have been identified to successfully adopt and implement JIP33 specifications. These include ensuring that the ‘brand’ visibility of the JIP33 specification is maintained as it moves through the supply chain so that it will be recognised, and suppliers can respond appropriately. It is also important that the specifications are being used ‘as-is’; overlaying or modifying the JIP33 specifications will erode their value. JIP33 is continually updating its processes, including how to minimise overlays to specifications when maintaining or expanding the scope of existing specifications.

Looking forwards

The application of JIP33 specifications is not limited to greenfield upstream capital projects. The specifications are also being actively used in brownfield and low-carbon applications. One of the selection criteria recently added for development topics was low carbon/energy transition applicability. This helps broaden the application past the traditional oil & gas usage into new businesses that many in the sector are now active in. For the flow control industry, this means that standards will need to meet environmental objectives such as:

- Address the reduction of fugitive emissions and define the respective quality requirements

- Include data requirements that certify the carbon footprint of flow control equipment

- Include information requirements to mitigate material fraud in the energy sector

- Define new scope to cover applications in Hydrogen and CCUS

- Leave space for further innovation (like additive manufacturing)

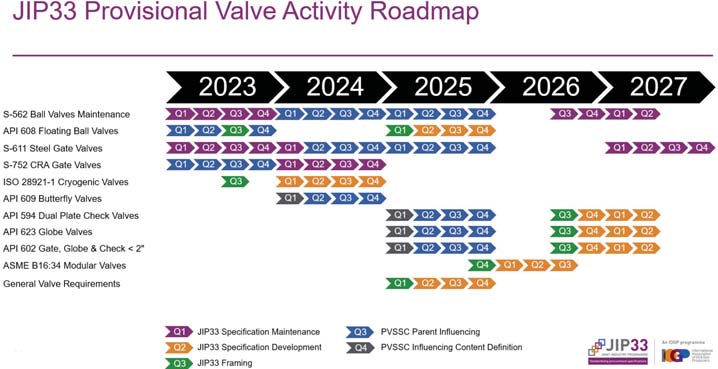

These elements will be covered in JIP33 in new and existing specifications as long as they form existing gaps in industry standards. A provisional roadmap for developing JIP33 specifications for valves is shown in Figure 4.

Conclusion

JIP33 has been a great success in the short time it has been active. The JIP33 Program is now actively engaging with additional operators and EPCs to further adoption across the industry. A large number of projects are now using JIP33 specifications, and large volumes of equipment specified by JIP33 have been procured since the oil & gas industry started to recover from the pandemic.

While there is still a journey for many companies to go through to get the full cultural and behavioural changes required throughout their organisation, there is the full support of executives from the major international and national oil & gas companies driving this program and making it go from strength to strength. The program continues to welcome increased participation of suppliers in the program, welcomes their input at all stages of the process, and actively encourages those who wish to know more to reach out to the JIP33 Project Team in this exciting endeavour.

JIP33 beyond oil & gas

David Harris has been the Specifications Manager of the JIP33 project at IOGP since 2020. He highlighted how the project is having a positive effect well beyond the oil & gas industry.

David Harris has been the Specifications Manager of the JIP33 project at IOGP since 2020. He highlighted how the project is having a positive effect well beyond the oil & gas industry.

“When JIP33 was set up, it was aimed at large upstream oil & gas projects that, in terms of global expenditure, are second only to aerospace. However, it’s now also being applied to the maintenance and upgrades of existing facilities.”

“Beyond oil & gas, the program is also relevant to low-carbon projects, from the electrification of existing facilities to carbon capture. JIP33 specifications have already been applied to some publicly announced carbon capture projects in the UK and Europe, and several of our new topics will have applications for net zero and low carbon projects. For example, specifications for power cables to offshore oil & gas facilities have applicability to offshore wind farms.

New energy projects will benefit from the standardisation, experience and competency present in traditional oil & gas engineering. While they may have a different economic base and risk profile, much of the subsea knowledge required for e.g. carbon capture is well-known within oil & gas. Notably, for new energy projects to succeed, they need to operate long-term, and the oil & gas industry understands long-term engineering reliability very well.”

“An important advantage of JIP33 and the IOGP, in general, is that we can publish best practices and guidelines in a reasonably short period of time. We’re happy for these to be picked up by international standards organisations to form the basis for international standards. There’s a lot of exciting innovation in the global low-carbon energy industry, and some of the foundational principles from big oil & gas projects also apply to them. We have a thorough understanding of operational integrity and excellence.”

About this Featured Story

This Featured Story is an article from our Valve World Magazine, May 2023 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”