In the August edition, the growing importance of tackling fugitive emissions was explored. These emissions, particularly from Volatile Organic Compounds (VOCs), are not only environmentally damaging but also costly due to inefficiencies and regulatory penalties. Central to leak prevention are stem seals, and ISO 12101 was introduced as a new standard to guide their testing and qualification. In this second part, we take a closer look at the standard itself, its scope and what it means for real-world implementation.

By Colin Zegers, ITIS BV

Many in the industry may think, “Do we really need another standard?” But the answer is increasingly clear: yes. Regulations are tightening. Across the globe, governments and permitting bodies are placing more emphasis on reducing the release of VOCs and even more hazardous substances like Substances of Very High Concern (SVHCs). In some countries, industrial plants are already legally required to implement LDAR (Leak Detection and Repair) programmes. These programmes involve systematic identification, monitoring and repair of leaks, with clear documentation, retesting and follow-up built into the process.

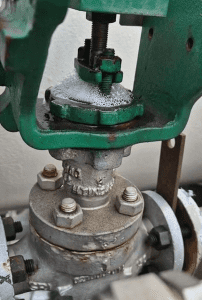

While LDAR has become a standard approach for VOCs, regulatory focus is now expanding to include SVHCs. Within the European Union, these substances are governed by the REACH Regulation. Outside the EU, similar rules exist, such as the U.S. Toxic Substances Control Act (TSCA). In all cases, the message is clear: emissions of hazardous substances must be minimised to protect human health and the environment. Against this backdrop, ISO 12101 offers a practical tool that supports emissions reduction and promotes better stem seal design through clearly defined testing and qualification procedures. The standard defines how to evaluate the performance of stem seals under controlled conditions using a dedicated test fixture. Rather than testing the complete valve, it allows manufacturers to qualify stem seals in a standardised way, ensuring the results can be compared across different suppliers and applications.

Scope of ISO 12101

ISO 12101 applies to stem seals used in industrial valves. It does not replace full valve type testing or valve production testing, nor is it mandatory for qualifying seals before performing ISO 15848-1 testing. However, it offers clarity and structure, especially where valve and stem seal combinations have historically been a guessing game. Importantly, ISO 12101 accommodates a broad spectrum of stem seal technologies. It covers compressible packings (both with and without live loading), elastomeric elements and pressure-energised designs, making it applicable to virtually all commonly used sealing solutions in today’s valve market. The standard is relevant for both on/off and control valves, and it applies to stem seals used in multi-turn, linear and quarter-turn valves. What truly sets ISO 12101 apart is the way it replicates real-world stem movements, something that directly affects the mechanical load and sealing behaviour of the packing. To ensure this realism, the standard includes test protocols for three distinct stem motion types:

• NRRS – Non-Rotating Rising Stem: Common in gate valves, where the stem travels vertically without rotation.

• RNRS – Rotating Non-Rising Stem: Typical of ball valves, where the stem rotates in place without vertical movement.

• RRS – Rotating Rising Stem: Seen in globe valves, where the stem both rotates and rises during actuation

These distinctions are more than just theoretical. A stem seal that performs well under one movement type may show degradation or leakage when subjected to a different motion pattern. ISO 12101 addresses these differences directly by defining motion-specific testing procedures—ensuring performance is validated in conditions that closely mimic actual service.

Transparency

The value of ISO 12101 lies in the transparency it brings. For the first time, valve manufacturers, service providers and end users can ask stem seal suppliers for concrete test results, emission rates and application-specific performance data. For instance, a valve manufacturer aiming to meet AH-level fugitive emission standards under ISO 15848-1 doesn’t need to waste time testing a seal certified only to CH level. Likewise, a seal that has only been tested at room temperature offers no guarantees for cryogenic service at -162°C—the operating temperature of LNG. To illustrate the impact, imagine if car manufacturers had to guess which tyre would work best for each model—testing each one themselves to ensure performance in snow, on highways or under load. That would be unthinkable today. Instead, tyre suppliers provide precise data on speed ratings, tread depth, load capacity, installation direction and environmental suitability. Yet in the valve world, this level of detail has often been missing when it comes to stem seals. ISO 12101 changes that. It encourages stem seal manufacturers to adopt the same level of transparency and performance disclosure that we take for granted in other industries. Stem seal manufacturers stand to benefit the most from ISO 12101. But with that benefit comes responsibility. Manufacturers must now be ready to provide accurate, detailed information on:

• Suitable media, pressure, and temperature ranges;

• Installation instructions (e.g., how graphite packings should be compressed);

• Required compression rates to avoid under- or over-compression;

• Cycling speeds, torque requirements and retightening intervals;

• Behaviour during thermal cycling, such as leakage caused by relaxation;

• Expected number of mechanical cycles;

• Projected long-term performance

In practice, many of these factors were not consistently documented or communicated. But they really matter. Poor installation or missing guidance can lead to leaks, unnecessary downtime and even environmental incidents. ISO 12101 aims to change that by ensuring expectations and performance are aligned—from the manufacturer’s bench to field operation.

Valve manufacturers remain responsible for the overall performance of their products, including the complete assembly and stem sealing system. This responsibility is typically demonstrated through ISO 15848-1 testing. That obligation remains unchanged. However, ISO 12101 now gives valve manufacturers the ability to request verified test results and specific technical data from stem seal suppliers, allowing for more reliable integration and performance assurance.

Upgrading existing valves

Many valves currently in service are leaking—and often unnecessarily. Laboratory testing is useful but usually proves that a valve or stem seal can meet certain conditions once. It says something about a batch, a design or a specific application. This is especially useful for new builds or plant expansions, as often seen in countries like Germany and Belgium where authorities increasingly demand emissions testing.

However, what about the hundreds of thousands of valves already in service? These represent the majority of the installed base and are often overlooked. ISO 12101 presents an opportunity to change that by enabling plant owners and repair shops to bring existing valves up to modern sealing standards. Instead of replacing valves, they can be upgraded using validated stem seal systems, adjusted dimensions and tighter tolerances based on ISO 12101 guidance. Whether it’s during scheduled maintenance or a mid-life overhaul, plant operators now have access to test reports and stem seal data that allow them to make informed decisions. Valve overhaul shops can work with stem seal suppliers to apply validated geometries, installation parameters and stem finishes that reduce emissions, extend seal life and improve valve performance.

Flexibility in test setups

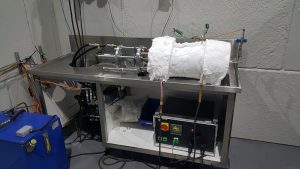

Early drafts of ISO 12101 proposed that stem seals must be tested in a fully standardised test fixture, with exact material specs, dimensions, tolerances and surface finishes. This approach was aimed at ensuring comparability of results. After extensive discussions with the British Valve & Actuator Association (BVAA), the European Sealing Association (ESA) and the Fluid Sealing Association (FSA), Technical Committee ISO/TC 153/WG 5 on Fugitive Emissions agreed to an important compromise: allowing the use of test valves instead of dedicated test fixtures. This approach makes sense, as developing custom fixtures for every seal design would be costly, time-consuming and overly restrictive. Test valves allow for more flexibility as they reflect real-world usage and are especially useful for large or high-pressure valve designs where custom fixtures would be impractical. Stem seal manufacturers or test laboratories must document all design details of the test fixture or test valve in the final report to ensure test traceability.

In short, ISO 12101 now supports three options:

• Standardized test fixture;

• Manufacturer-specific fixture;

• Test valve.

This hybrid approach supports innovation without sacrificing test validity. It recognises the diversity of valve and seal designs across the industry while maintaining the discipline needed for credible performance verification.

Implementing ISO 12101: Practical perspectives

For valve manufacturers and valve repair shops alike, the real value of ISO 12101 lies in how the test method is used to guide decisions and improve outcomes. A valve manufacturer looking to benefit from ISO 12101 should start by working closely with stem seal suppliers. This means asking for ISO 12101-compliant test reports that include real data on emissions, cycling behaviour and temperature performance. Equally important is obtaining the dimensional data, tolerances, surface finish requirements and detailed installation instructions needed to correctly integrate the stem seal into the valve design. Without this information, even a well-qualified seal may fail to deliver its tested performance in the field. These results and specifications should match the actual stem geometry and motion type used in the manufacturer’s valve design. The goal is to verify that the tested conditions and assembly parameters align with the real-world application. Based on these insights, manufacturers can select seals with proven performance and build them into their valve platforms, reducing development risk and increasing confidence during ISO 15848-1 certification. Over time, these validated combinations, including the accompanying dimensional and installation data, can become part of the company’s design standards or preferred supplier programmes.

For repair shops and maintenance contractors, ISO 12101 provides an opportunity to source seals that have been pre-qualified to ISO 12101 instead of relying on general-purpose packing or old repair habits. During an overhaul, technicians can consult the original stem dimensions and match them with ISO 12101 test data, choosing seals that fit and perform reliably under expected loads, motions and temperatures. By following the installation parameters defined in the ISO 12101 report (such as compression rate, stem finish and torque), repair professionals can upgrade valves to modern sealing performance levels, without replacing the valve body itself. In effect, ISO 12101 becomes a toolkit for smarter, cleaner and more traceable valve overhauls. These implementation steps are not theoretical, but represent a practical path to lower emissions, longer seal life and better field performance.

About the author

About the author

Colin Zegers is the founder and managing director of ITIS BV, an ISO 17025-accredited test laboratory and Conformity Assessment Body (CAB) based in the Netherlands. With 27 years of experience in leak testing, valve and product testing, and industrial inspections, he has built a reputation for combining technical depth with practical implementation.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, September 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”

About the author

About the author