Jewellok Technology Co., Ltd., an innovator in ultra-high purity (UHP) gas delivery systems and fluid control solutions, has unveiled its groundbreaking Photovoltaic Specialty Gas Cabinet and VMB Gas Cabinet. These cutting-edge products are poised to revolutionize the photovoltaic (PV) industry by enhancing safety, efficiency, and precision in gas handling processes critical to solar cell manufacturing and renewable energy production.

The Photovoltaic Specialty Gas Cabinet represents a leap forward in UHP gas storage and distribution. Designed specifically for the rigors of photovoltaic production, this cabinet features fully automatic gas monitoring and control systems that ensure zero contamination and optimal flow rates. Built with electropolished 316L stainless steel interiors achieving a 5Ra surface finish, it prevents particle generation and maintains gas purity levels exceeding 99.9999%—critical for preventing defects in solar cell efficiency. Advanced sensors integrated into the system provide real-time data on pressure, temperature, and leak detection, allowing for predictive maintenance and reducing downtime by up to 30%, according to internal testing.

One of the standout innovations is the cabinet’s modular design, which allows for easy scalability. Manufacturers can customize configurations to handle multiple gas types simultaneously, supporting the transition from traditional silicon-based PV to emerging technologies like perovskite and thin-film solar cells. This flexibility not only streamlines operations but also aligns with sustainability goals by minimizing gas waste through precise dispensing mechanisms.

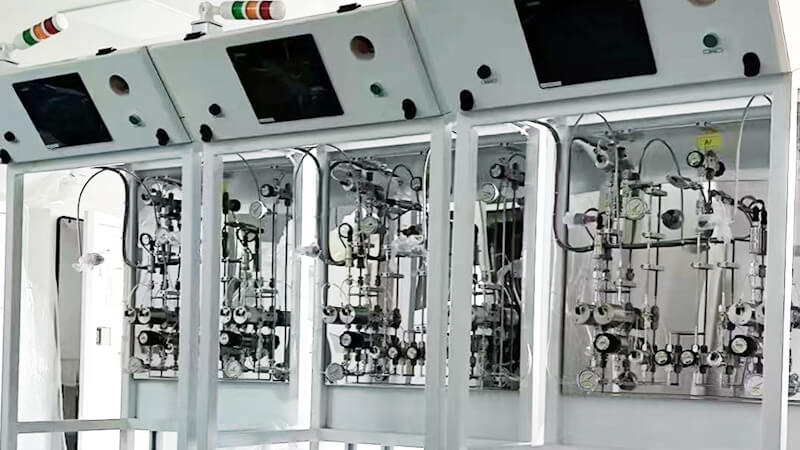

VMB (Valve Manifold Box) Gas Cabinet, which focuses on precise gas mixing and delivery. This semi-automatic or fully automatic system incorporates high-pressure pneumatic diaphragm valves and pressure regulators engineered for extreme conditions, including corrosive media and temperatures up to 200°C. The VMB’s fast-response control valves guarantee consistent flow rates, even under fluctuating demands, making it ideal for integrated circuit and optoelectronic applications within the PV supply chain. Its compact footprint and user-friendly interface enable seamless integration into existing cleanroom setups, reducing installation time by half compared to legacy systems.