Cryo testing of control valve

Prioritising custom engineering, investing in employees and leveraging global synergies within the KOSO Group, KOSO India takes to the cover of Valve World Magazine to showcase its journey and share its new developments.

By Lyndsey Denton-Fray, Valve World

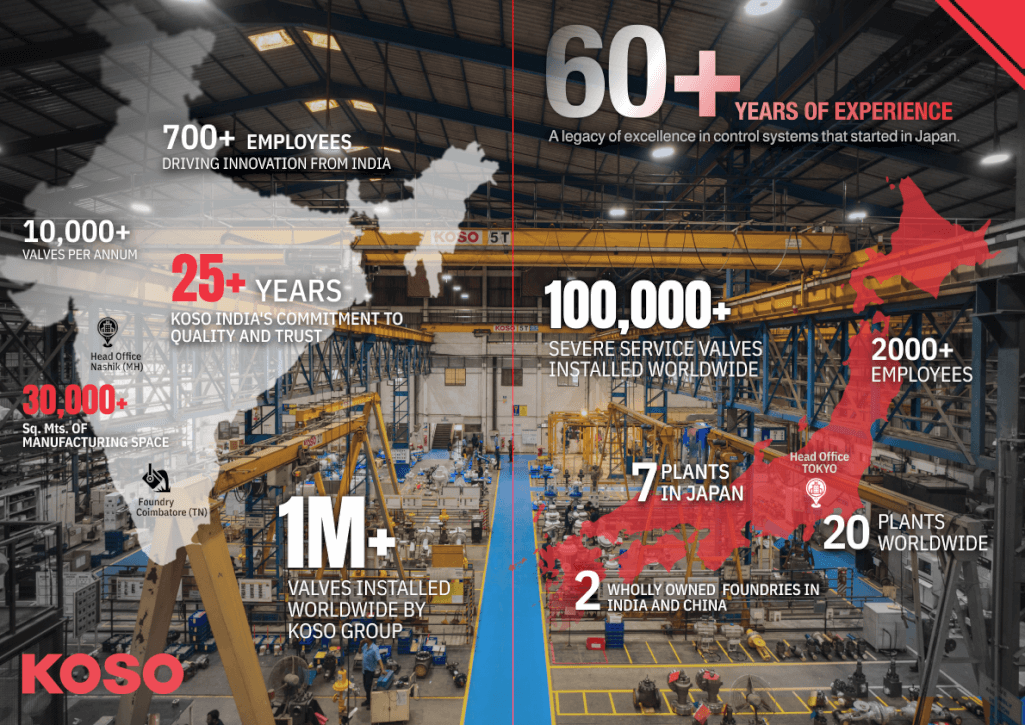

When a manufacturing company in India becomes one of the largest producers of control valves in the country, it’s worth asking how it got there. With 60 years in the business, the family-owned Japanese KOSO Group has operations in more than ten countries, with KOSO India employing over 700 people and a USD 100 million plus business.

But let’s rewind to 2005: “We were 28 people, turning over less than a million dollars,” recalls the company’s long-serving Managing Director Gaurav Gupta. “That’s when KOSO Group invested in the business, bringing deep industry understanding and adding resources in land, building, machines and most importantly, people.”

From those modest beginnings, KOSO India now exports 80% of its production, supplying customised valves for mission-critical applications to customers across the globe. It is a transformation driven by strategic clarity, investment in talent and a refusal to compromise on quality.

Strategic growth and family dynamic

KOSO India’s growth strategy has a clear focus on high-performance control valves for oil & gas and power applications. With technology from Japan and the UK and a fully owned captive foundry in India, KOSO India has an edge like no other.

“We want to change the perception and narrative of how people might envisage a plant in India,” voices Mr Gupta. “This is a global manufacturing plant that could be set up anywhere in the world and you wouldn’t know where it was if you were inside. It is a world-class manufacturing facility.” With such a plant in progress and being a family-owned company, one of KOSO India’s number one advantages is speed in decision-making.

“Being a family-owned company enables us to create a long-term strategic focus, not just looking from quarter to quarter,” explains Mr Gupta. “We have the space to make quick decisions and can invest in capacity or technology without short-term shareholder pressure. And with the KOSO Group’s global reach, we have the resources and market access of a large enterprise but the agility of a startup.”

That agility shows in KOSO India’s positioning. While some KOSO Group companies produce higher volumes, KOSO India specialises in customised, engineered-to-order valves for critical applications designed for a specific process, not pulled from a catalogue.

Winning in demanding markets

One of the company’s most impressive success stories is its expansion into the Middle East, a market where technical compliance and delivery reliability are paramount. While these companies need quick deliveries, they often need very technically reliable products. This is where KOSO India have been able to supply deliveries with strict time limits and continuous before and after support.

“When we entered the Middle East market in 2009, the first thing we did was establish a strong aftermarket service presence,” explains Mr Gupta. “Our team is available 24/7, and that level of commitment is a big reason customers choose us over the competition. It is often not on price but rather on trust and performance.”

KOSO India has developed anti-surge valves and choke valves tailored for offshore platforms, ensuring zero failure tolerance. The company is also looking at supplying HIPPS and ball valves in the area.

Engineering achievements

The delivery of a 30-inch, 1500# globe valve for a Middle Eastern oil major was one of the largest and most complex valves ever produced by the KOSO Group.

“Many companies would shy away from such an order,” says Mr Gupta. “We took it on because I knew our engineering and execution teams could deliver. That’s the kind of challenge we thrive on.”

The entire internal surface was Inconel-clad, including areas inaccessible to machines, requiring skilled welders to work day and night. Weighing 26 tonnes, the valve was designed, built and tested entirely in-house, passing all inspections on the first attempt.

“What made this possible was the strength of our team and I’m proud to lead a group of such motivated, solution-orientated engineers,” beams Mr Gupta. “Their dedication and problem-solving mindsets give me the confidence to make bold strategic decisions. It’s this combination of technical excellence and human commitment that continues to fuel the growth and reputation of KOSO India.”

The company is also developing valves for green hydrogen applications, focusing on advanced sealing materials to prevent leakage and degradation. Its acquisition of Italy’s Paladon Systems, specialists in electrohydraulic and pneumatic actuators, has enabled full integration of actuation and valve systems for demanding applications like HIPPS.

Expansion and coordination

To meet rising demand, KOSO India is building a new facility and reorganising its current facilities.

“The new facility we are building, which should be ready by November, will be a dedicated machine shop for the company,” explains Mr Gupta. “This will make space for plant one to be a completely dedicated ball valve facility and for plant two to be a space dedicated to control valves.”

Whilst expansion is on the horizon, this does not mean a shift of focus.

“This isn’t about shifting into mass-produced standard valves,” stresses Mr Gupta. “Our focus remains on high-end ball valves – metal-seated, soft-seated, top-entry, suited to LNG, high temperature and other critical applications. The new facility will give us layout efficiencies, a dedicated machining area and room to innovate without compromising our customised approach.”

Quality in its culture

For KOSO India, quality is not a departmental goal but embedded in the company’s culture.

For KOSO India, quality is not a departmental goal but embedded in the company’s culture.

Every valve for oil & gas or power projects undergoes multi-tier validation, rigorous documentation and often real-time third-party inspections. Remote testing, first adopted during the COVID-19 pandemic, is now standard practice, with HD video feeds, ERP integration and the ability to record and share test results. “The certainty of outcome is why customers come to us,” says Mr Gupta. “When you place an order with KOSO India, you know you’ll get the right product, with the right quality, on time.”

Sustainability in practice

KOSO India is more than aware that valve manufacturing is resource intensive. With that in mind, the company is continuously building on its ability to be sustainable and efficient.

Sixty percent of KOSO India’s power comes from solar, and its effluent treatment plant (ETP) ensures zero discharge. Packing boxes are made out of recyclable material where possible and globally acceptable materials are used when available.

Zero-leak sealing systems are now standard for hazardous applications involving ammonia, hydrogen or cyanide, and most valves meet Class A fugitive emission standards. R&D continues to explore environmentally friendly materials and longer-lasting designs that reduce lifecycle impact.

“It’s not about one-off initiatives but about maintaining what we’ve achieved and constantly improving,” says Mr Gupta. “We are continuously trying to reduce our footprint without compromising on quality.”

People programmes

Whilst taking care of its customers and the environment are big priorities for KOSO India, so is taking care of its employees. One of the programmes that KOSO India runs is the Kaisen programme, where employees are invited to share their ideas for improvement from the shop floor, with the best presented and rewarded each quarter.

Whilst taking care of its customers and the environment are big priorities for KOSO India, so is taking care of its employees. One of the programmes that KOSO India runs is the Kaisen programme, where employees are invited to share their ideas for improvement from the shop floor, with the best presented and rewarded each quarter.

“This programme is a huge benefit for the company,” shares Mr Gupta. “Nobody can bring these kinds of ideas just by sitting in an office and we as a company recognise this and the ideas of our people who are working on the shop floor.” Another programme is an employee-run welfare society that helps contribute to employee livelihoods, such as money for weddings, housing or higher education. Each employee pays into the fund and can then loan money for specified needs. This society has strengthened loyalty and engagement for the company, with attrition being exceptionally low and employees serving 20 years or more. “Employees are not just part of the company, but they are the very foundation it stands on,” says Mr Gupta. “When you look after people, they stay. And when they stay, they give back even more.”

Digital transitions

Digital systems developed during the pandemic have become part of daily operations. Remote testing and ERP integration now offer customers greater transparency and efficiency.

Looking ahead, KOSO India is investing in IoT-enabled smart valves with embedded sensors for real-time condition monitoring. These will enable predictive maintenance, reducing downtime and improving asset performance, particularly in remote or high-risk environments.

The company is also targeting the nuclear sector, especially Small Modular Reactors, with valves designed for stringent safety and redundancy standards, sealing, corrosion and temperature variation, alongside continued innovation in green hydrogen systems.

Part of something bigger

KOSO India’s philosophy is simple: grow without losing identity.

“We’re not chasing volume for the sake of it,” concludes Mr Gupta. “We’re expanding capabilities where it makes sense, but our core will always be high-performance, custom-engineered solutions. That’s what makes us trusted in mission-critical industries. ‘Part of something bigger’ isn’t just a phrase but a mindset for us. We have a shared mission to solve real-world, high-stake challenges.” KOSO India’s family-owned presence resonates in its performance, care and perseverance with its employees and clients alike. Whilst decisions can be made quickly, responsibility for its work, people and performance are at the heart of what the company contributes.

Dive Deeper into Valve World

Enjoyed this featured article from our October 2025 magazine? There’s much more to discover! Subscribe to Valve World Magazine and gain access to:

Advanced industry insights

Expert analysis and case studies

Exclusive interviews with valve innovators

Available in print and digital formats.

Breaking news: Digital subscriptions now FREE!

Join our thriving community of valve professionals. Have a story to share? Your expertise could be featured next – online and in print.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”