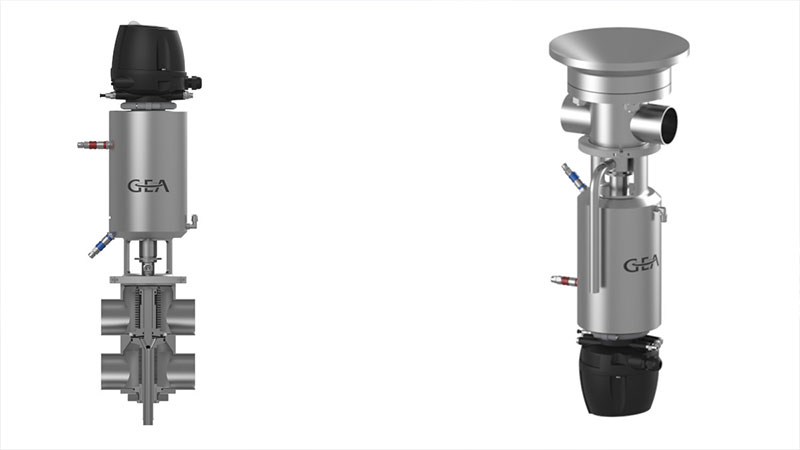

GEA is expanding its valve portfolio with the GEA Aseptomag® LV leakage valve. The mix-proof double-seat valve is designed for manufacturers of foods and beverages, as well as pharmaceutical products, who maintain high safety standards in their UltraClean process lines. Typical examples are products with an extended shelf life (ESL) such as soft drinks, fruit juices, and milk-based and lactic acid fermented products, along with plant-based alternatives sold chilled by retailers. Focusing on equipment flexibility, the design features significantly mitigate the risk of contamination in this hygiene class. In addition, products become more durable – with less preservatives.

The new leakage valve closes the gap in GEA’s valve portfolio between media that need to be processed hygienically and those where a consistently aseptic process is called for. The former applies to applications with lower microbial risk, and the latter to highly sensitive products used as for medical and infant feeding purposes. “Most customers create products that are at the second-highest hygiene level, ‘UltraClean’. These products carry a greater hygiene risk than classic hygienic applications, but they still have no need for the high-end version of a complete aseptic process chain,” explains Pascal Bär.

Just like the entire GEA Aseptomag® range, the new LV valve uses stainless steel bellows. These block microorganisms from being drawn uncontrollably into the product chamber, which keeps the process and the product safe. With hermetically sealing valve stems, bellows valves achieve a higher hygienic standard, which makes for better product quality and a longer minimum shelf-life.