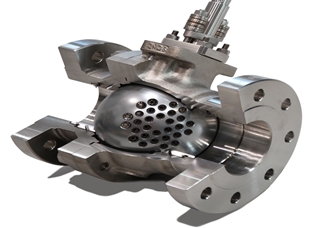

Metso’s new Neles Q2-Trim ™ reduces noise up to 30 decibels compared to a typical control valve helping process industry customers to improve personnel and plant safety while simultaneously increasing efficiency and reliability.

Metso’s new Neles Q2-Trim ™ reduces noise up to 30 decibels compared to a typical control valve helping process industry customers to improve personnel and plant safety while simultaneously increasing efficiency and reliability.Metso’s frontrunning Q2-Trim technology is combination of various techniques resulting multiple benefits for customers. By eliminating the damage that high noise can cause to process plants, employees and surroundings Q2-Trim ensures safe working environmental for personnel and stabile process control and longer uninterrupted plant runtime.

By reducing noise and related vibration to acceptable levels Q-Trim technology also protects process equipment thus lowering the operating costs and minimizing the need for spare parts for valves and other accessories.

Combining Q-Trim technology with quarter-turn valves results in emission levels that meet all relevant industry standards. Compact size and selection of mounting positions means less pipeline support and easier piping layout design.

New Neles Q2-Trim is an addition to the existing Q-Trim technology and is available for pressure classes ASME 150 – 600 in sizes 2″ – 16″ and PN 10 – PN 100 in sizes DN 050 – DN 400 in standard ball valve offering. The standard trim material is stainless steel, Q-Trims made of special alloys and larger sizes are available on request. Q2-Trim has several key application in various fields in power, oil & gas, petrochemical, industrial gas and chemical industries.