Explore the critical role of valve auxiliaries in maintaining valve functionality and reliability and discover effective strategies for mitigating associated risks throughout the valve’s service life.

By Essam Arfaj, Bader Jarallah, and Mohanned Tarabzouni – Aramco

Valve piping auxiliaries, including drains, vents, bypass and equalizing lines, are essential elements that ensure valve functionality and reliability throughout the intended service life. To achieve the intended functionality, valve auxiliaries must be properly designed and maintained. Failure to maintain healthy piping auxiliaries will not only affect valve functionality but may also impose serious risks to operating facilities, such as external leaks. In this paper, actual failure case histories are examined to determine root causes and provide guidelines on how to design and maintain these auxiliaries throughout the valve’s design life.

Understanding valve auxiliaries

Valve auxiliaries are connections and components fitted to main isolation valves to support operations and ensure sustainable production without interruption. These typically include small piping, extended tubing, and emergency injection lines, in addition to associated fittings. The following are the most commonly used auxiliaries in pipeline applications:

- Drain and vent: A connection provided in a valve body, bonnet, or for the purpose of releasing fluid.

- Bypass/equalizing line: Lines utilized to isolate mainlines for maintenance/stroking activities, acting as secondary mainlines. They can function as a piping loop to permit flow around a valve closure member in its closed position.

- Relief lines: A connection designed to actuate automatically to reduce internal pressure when its pressure setting is exceeded.

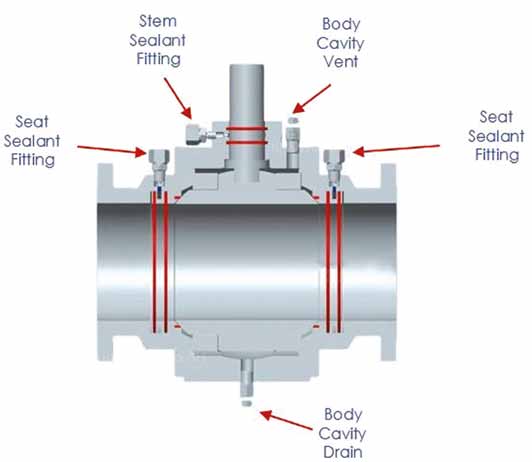

- Injection fittings: Utilised to inject products into the valve packing and seat systems

to achieve isolation or protect them from damage.

These auxiliaries experience high pressure and, in some cases, high temperatures, in addition to being exposed to hydrocarbons. To maintain operations and prevent failures, all associated auxiliaries need to be properly designed, selected and inspected.

Associated risks

Failure to maintain healthy valve auxiliaries can lead to serious risks in operating facilities. These risks range from operational interruptions to severe outages. The primary failure modes include:

- External corrosion

- Internal corrosion

- Environmental cracking

- Third-party damage

External corrosion

External corrosion is a common failure mode in valve auxiliaries, especially in buried and insulated valve installations. The extent of the concern includes multiple factors such as soil characteristics, environmental conditions, coating specifications and selection, in addition to the material suitability of these components. Figure 3 shows an example of an external leak in a drain connection of a buried pipeline valve due to external corrosion.

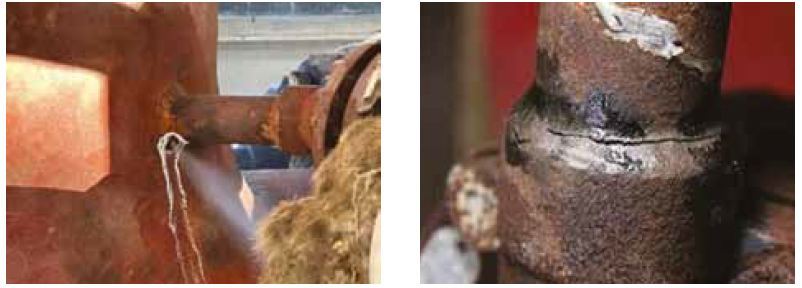

Internal corrosion

Internal corrosion is another common risk in valve auxiliaries, which are considered operational dead legs: stagnated corrosive fluids within areas of accumulation can lead to accelerated localised corrosion. Figure 4 demonstrates a typical failure of valve auxiliaries due to internal corrosion. To prevent corrosion, the material of the valve auxiliary should be made of proper corrosion-resistant alloys that can withstand both internal and external environments. As a rule of thumb, valve auxiliaries should have corrosion resistance at least equal to the trim material of the main valve. In some severe services, such as buried and insulated applications, auxiliaries should be protected from external corrosion with a suitable coating system.

Environmental cracking

As these auxiliaries are exposed to corrosive fluid environments and are subject to tensile hoop stresses, they are prone to environmental cracking mechanisms. Stress corrosion cracking (SCC) is commonly encountered in sour environments. Ensuring proper material selection is a key factor in preventing such failures. As there is limited control in these environments, the main prevention methods involve choosing a non-susceptible material as defined in the applicable design codes.

Fatigue

Fatigue due to flow-induced vibration is another risk, especially for small-bore equalising lines. Mitigation methods include increasing system rigidity through greater pipe wall thickness and providing a robust support configuration.

Third-party damage

Third-party damage is another risk, especially in the valve’s early stages when improper handling can cause damage to valve auxiliaries. Figure 6 demonstrates examples of damage to valve auxiliaries due to improper handling and transportation. To minimise the risk of third-party damage, valve auxiliary piping should follow the valve contour as closely as possible and be rigidly connected to the valve body.

Risk mitigation methods

Mitigation starts at an early stage during valve design: Valve auxiliaries require robust and solid design in terms of material selection and corrosion resistance to withstand the designated pressure conditions and function as intended. Periodic and preventative maintenance should always be part of ensuring their condition and performance across the design life of the main line.

To maintain the condition of the auxiliaries throughout the intended valve life, valve auxiliaries should be subject to robust inspection programs. These include visual inspections for signs of rust, external corrosion, oxidation, external leakages, damage, cracks and general condition and integrity of the coating. Non-destructive examination (NDE) methods such as wall thickness volumetric examination (RT/UT) are recommended to confirm the remaining wall thickness. When feasible, a cavity flushing program is recommended to drain accumulated products and minimize dead leg impacts.

The frequency of inspection and maintenance for auxiliary systems can vary depending on several key factors, including material of construction and pipeline operating conditions.

Specifications and design considerations

To prevent the highlighted risks and associated failures, valve auxiliaries should be designed and specified through robust standards. Key considerations include:

- Appropriate features for buried service (e.g., stem/shaft extensions, sealed interfaces)

- Suitable sealant injection fittings with safety features

- High-grade materials (e.g., SS 316L minimum for piping, valves and fittings)

- Consistent coating systems

- Proper configuration of drain, vent and sealant injection lines

Inspection and maintenance

Develop comprehensive inspection programs covering both the main valve and associated auxiliaries. Key aspects include:

- Regular cleaning, lubrication, and gasket replacement

- Integrity checks of piping and connections

- Visual inspections for damages and abnormalities

- Periodic non-destructive examination (NDE) methods, such as ultrasonic testing

- Flushing programs to minimize dead leg impacts

- Monitoring for corrosion, leaks or blockages

The frequency of inspection and maintenance should be tailored based on factors such as:

- Pipeline operating conditions

- Environmental factors

- Valve usage patterns

- Material durability and corrosion resistance

Conclusion

Ensuring the integrity and reliability of valve auxiliaries is as crucial as maintaining the main valve itself. Any risk imposed on these components can lead to unplanned outages and shutdowns. By implementing proper design, material selection, specification, inspection and maintenance practices, operators can ensure the readiness of valve auxiliaries and prolong their design life, ultimately sustaining operations and production.

About the authors

Bader Al-Jarallah is a Valve Engineering Consultant at Saudi Aramco Central Engineering. He served as the Chairman of the Valve Engineering Standards Committee and is a member of several engineering standards committees. Bader holds a B.S.

in Mechanical Engineering and an M.S. in Materials Engineering. Since joining Saudi Aramco in 2000, he has dealt with various aspects of design, commissioning, operations, troubleshooting and maintenance.

Essam Arfaj is an Engineering Consultant with 25 years of experience in the oil and gas industry. His expertise spans technical leadership, management, professional engineering and human resources.

Mohanned Tarabzouni is a Piping and Valves Engineer in the Pipeline Technical Support Division of Saudi Aramco. He holds a B.S. in Mechanical Engineering and an M.S. in Pipelines, working for the Projects & Technical Support Department.

Dive Deeper into Valve World

Enjoyed this featured article? There’s much more to discover! Subscribe to Valve World Magazine and gain access to:

- Advanced industry insights

- Expert analysis and case studies

- Exclusive interviews with valve innovators

Available in print and digital formats.

Breaking news: Digital subscriptions now FREE!

Join our thriving community of valve professionals. Have a story to share? Your expertise could be featured next – online and in print.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”