POSV (pilot-operated safety valves) only react to the pressure at the valve inlet and are not affected by the back pressure. The maximum back pressure of a POSV is 70% of the set pressure as standard. But what to do if the back pressure is higher? To secure an injection system, a customer of LESER needed a POSV that could secure a process with 200 bar-g design back pressure at a set pressure of 207 bar-g. This is four times more than the standard API 526. LESER engineers solved this with a block body design that can withstand high outlet pressure.

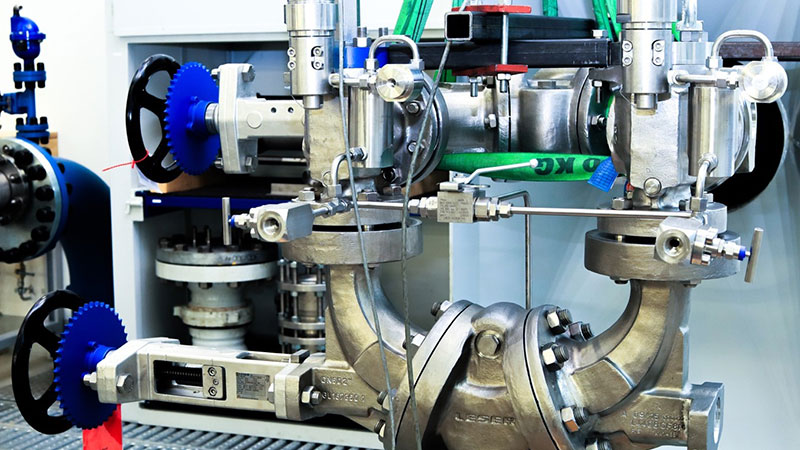

This is because the standard cast bodies are not designed for these high back pressures. In order to prove that the valve bodies manufactured for the first time comply with the regulations, tests were carried out on the LESER water test bench.

This approach expands the LESER POSV portfolio and makes it more flexible for different requirements.

To enable redundant overpressure protection with POSV in a change-over valve combination, the POSV must be equipped with the option “Remote Sensing”. Remote Sensing is a separate pressure tapping.

POSV has a very high capacity, which leads to inlet pressure losses through the supply line and the change-over valve. With the option “Remote Sensing” the pressure tapping is already done at the inlet of the change-over valve. In this way, the pressure loss occurring in the change-over valve is bypassed. LESER carried out validation tests for function, performance, and switching for these combinations on its own test bench in Hamburg.