Special process application utilising Neway 96” triple-offset butterfly valve

Neway Valve has consistently made strides in valve technology since its inception. From its early focus on general manual valves to its current position as a global leader in comprehensive industrial valve solutions, Neway has continually advanced what’s achievable in valve manufacturing.

By Melonie Dodaro and Laura Wang, Valve World

Neway Valve was founded with the vision of becoming a world-class valve manufacturer. The company has built its reputation on a foundation of exceptional quality. Elvin Feng, President of Neway Valve, explains, “For us, quality isn’t just about meeting international standards. It encompasses our entire business operation, from raw materials to customer service.”

This commitment to quality is evident throughout Neway’s operations. The company owns its foundries and forging plants, enabling stringent quality control from the very beginning of the production process. With three R&D centres worldwide and over 200 research personnel, Neway continuously invests in innovation and technical competence.

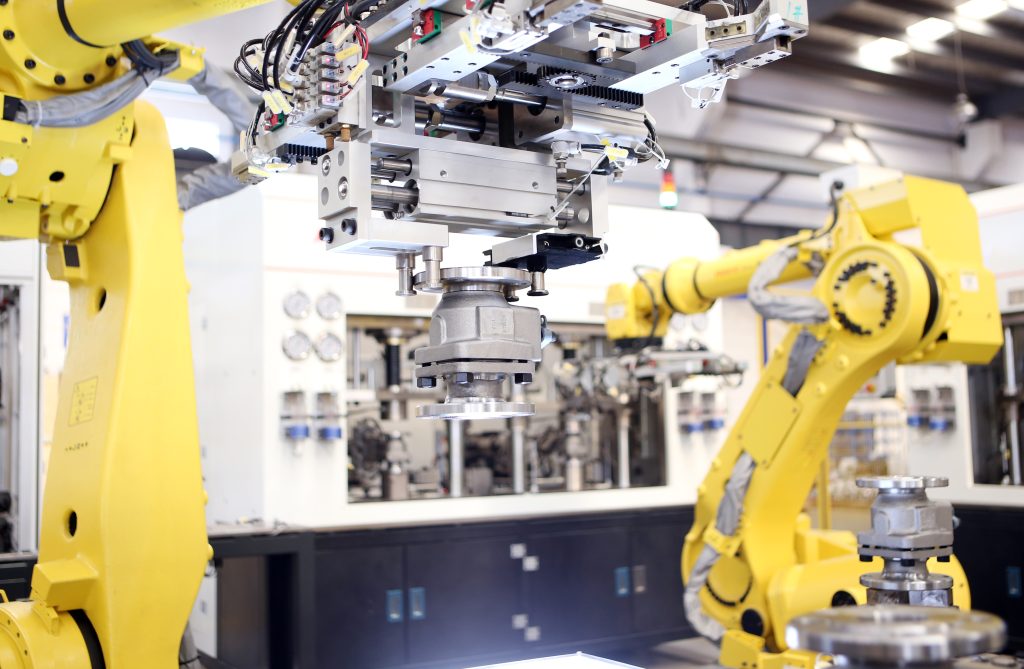

Automation the key to consistency and efficiency

Neway recognised early that automation would be crucial for maintaining consistent quality while increasing efficiency. The company has invested heavily in automated production lines for welding, coating treatment and pressure testing. Recently, Neway completed the commissioning of an automatic production line for floating ball valves.

For Neway, automation extends beyond robotic assembly lines. “Our goal is to optimise our entire operational process through IoT technology and big data,” Feng explains. “This approach will lead to higher efficiency, flexibility and responsiveness, ultimately driving innovation and sustainable development.”

The company is currently planning to upgrade its logistics and warehousing automation capabilities. This investment in automation is part of Neway’s broader strategy to enhance its competitive edge and ensure sustainable growth in the global market.

Setting the standard in valve technology

Neway’s expertise is recognised not only by its customers but also by industry bodies. The company has been invited to participate in the IOGP Standardisation project, becoming the one of the first valve manufacturers to do so. This involvement allows Neway to contribute its technical knowledge and quality control experience to industry standards, further cementing its position as a leader in valve technology.

Feng elaborates, “As the one of the first invited valve manufacturers, Neway has been participating profoundly in the IOGP Standardisation project. This means we have the chance to incorporate our technical advantages and experience in quality control into the related standards and realise further improvement.”

Diverse products for demanding applications

From its origins in general manual valves, Neway has expanded its product range to include automatic on/off valves and control valves. Today, the company offers solutions for a wide array of challenging conditions, including ultra-high temperatures, cryogenic environments, super-high pressures and highly corrosive applications.

This diverse product portfolio has enabled Neway to serve a broad range of industries, including oil and gas, chemical processing, power generation (including nuclear power), water treatment and new energy sectors. What sets Neway apart is its ability to offer differentiated products for specific market segments, showcasing the company’s technical prowess and market understanding.

Breakthrough in liquid hydrogen valves

One of Neway’s most significant recent achievements is in the field of liquid hydrogen valves. In 2023, the company became the first valve manufacturer to obtain certification for liquid hydrogen valves using the body-cavity cooling method. This breakthrough led to the development of a series of liquid hydrogen valves, including -253°C liquid hydrogen vacuum angle pattern globe valves, vacuum check valves, and emergency shut-off valves.

The successful delivery of nearly 100 liquid hydrogen valves marks a significant milestone for Neway and the industry as a whole. These valves met rigorous performance indicators and passed

third-party inspections, paving the way for wider application of such products globally.

Neway’s achievement in this area is particularly noteworthy. The company was awarded a special equipment type test certificate by the National Special Pump and Valve Engineering Technology Research Centre for its vacuum-jacketed cryogenic globe valve for liquid hydrogen service. Neway was the first valve manufacturer to use the liquid hydrogen internal cooling method for type testing, with the results meeting all standard requirements.

The test was performed according to T/CGMA 0405-2022 “General Test Method of Low Temperature Valve with Hydrogen Medium” at China’s aerospace product test centre. After 100 cycles of life testing with pressure, all performance metrics met the standard requirements of T/CGMA 0407-2022 “General Technical Specification for Hydrogen Cryogenic Valves”.

Innovation in high-temperature valves

Neway’s innovation extends to high-temperature applications as well. In 2023, the company successfully produced and tested a large-diameter pneumatic high-temperature triple offset butterfly valve for a domestic customer’s propane dehydrogenation project. With a design diameter of 96 inches and a design temperature of 704°C (1300°F), this valve represents a significant technical achievement.

To meet the challenging requirements of this application, Neway employed advanced techniques such as finite element analysis, thermal field analysis and fluid analysis. The company’s engineers developed a special customised design to address issues like stuck resistance and high torque at elevated temperatures.

This successful project demonstrates Neway’s capacity to tackle complex, high-specification valve requirements. It also highlights the company’s commitment to pushing the boundaries of valve technology to meet the evolving needs of its customers in various industries.

Expanding global reach

While Neway has strong roots in China, the company has always had global ambitions. Its “regional diversified strategy” has led to significant growth in markets beyond its traditional stronghold in America. The company has seen success in the Middle East and Southeast Asia and is now focusing on expanding its presence in Africa, Australia and South America.

Feng explains the rationale behind this strategy: “On one hand, this reduces excessive dependence on certain markets and raises overall risk resistance. On the other hand, exploring the potential of emerging markets leads to more points of business growth. The result will be enhanced company strength and brand image influence, and eventually helps to realise sustainable development of the company.”

Europe has become a key market for Neway. The company has been active in oil and gas, chemical, LNG and marine engineering projects in the region for years. More recently, Neway has turned its attention to Europe’s booming new energy sector, participating in projects related

to offshore wind power, carbon capture, hydrogen production and biomass energy. “The European new energy market has very high standards for product quality and performance,” Feng notes. “This challenges us to continuously upgrade our skills, techniques and product quality. It’s an opportunity for us to focus on technical innovation, increasing added value and enhancing our brand influence with the goal of sustainable development.”

Feng also highlights the alignment between Neway’s values and the European market’s emphasis on sustainability: “Being a listed company, Neway always advocates human rights, environmental protection, quality and sustainable development and upholds these factors as our core development principle. These factors are in line with the market trends and they are also key areas where Neway performs its social responsibility.”

Building a sustainable future

Sustainability is a core principle that guides Neway’s operations and future plans.

The company has set ambitious goals for reducing its environmental impact and improving employee well-being by 2030. These goals include:

-

Elvin Feng, President of Neway Valve Operation-related energy & emissions: Reduce absolute greenhouse gas (GHG) emissions from operations by 35%from 2021 to 2030. (By 2023, reached 29.42% / 35%)

- Operation-related waste: Reduce landfill intensity by 30% from 2021 to 2030. (By 2023, reached 7.12% / 30%)

- Operation-related water: Reduce water consumption from operations by 50%from 2021 to 2030. (By 2023, reached 48.67% / 50%)

- Employee health & safety: Reduce recordable injury frequency (RIF) by 30%from 2021 to 2030. (By 2023, reached 12.20% / 30%)

- Training: Increase the number of training hours per person per year

by 50% from 2021 to 2030. (By 2023, reached 25.5% / 50%) - Employee satisfaction: Increase the satisfaction of the company in the eyes of their employees from 90 points in 2021 to more than 95 points in 2030. (By 2023, reached 92 / 100)

As of 2023, Neway has made significant progress towards these goals, with particularly impressive results in reducing water consumption and increasing employee satisfaction.

Customer-centric approach and value-added services

Neway’s success is not just about producing high-quality valves; it’s also about understanding and meeting customer needs. The company has developed a deep understanding of service in the valve industry after serving diverse customers from various markets.

Feng explains, “Traditional manufacturers focus on production and selling of products with basic after-sales service, such as repairing and warranty. Such service model only meets elementary needs and features no advantage in the fierce market competition.” In contrast, Neway has been keen on providing value-adding services such as technical support, product training, standardised service, product traceability and full life cycle monitoring. The company sees this as an opportunity to establish strategic partnerships with its customers.

“This service model is beyond simple business transactions,” FENG says. “It’s about an in-depth cooperation based on common goals, mutual trust and long-term planning. It not only encourages resource sharing and complementing each other but also helps to reduce risk, enhance competitive power and innovation.”

Future focus globalisation and efficiency

As Neway Valve looks to the future, the company remains committed to its core values of quality, innovation and sustainability. A key focus for the company’s next stage of development is creating a sustainable supply chain.

“One of our key words for the next stage is ‘sustainable supply chain’,” Feng states. “As a matter of fact, Neway has outpaced many fellow players and is working on some energy-saving and emission reduction projects, like new energy, with remarkable international influence and pioneering spirit.”

The company plans to enhance its competitive power and reduce costs through globalised production sites and a strategic purchasing strategy. More importantly, Neway aims to leverage scale effects, carry out standardisation, automation, smart operation and upgrade data management to better serve global customers.

These strategies form the essential foundation of Neway’s globalisation and sustainable development. By continuing to invest in research and development, expand its global presence, and focus on environmentally friendly practices, Neway is well-positioned to meet the evolving needs of the valve industry while contributing to a greener, more sustainable future.

With its track record of breakthrough technologies, commitment to quality and focus on sustainable practices, Neway Valve is not just keeping pace with industry trends – it’s helping to shape the future of valve technology for decades to come.

Dive Deeper into Valve World

Enjoyed this featured article? There’s much more to discover! Subscribe to Valve World Magazine and gain access to:

- Advanced industry insights

- Expert analysis and case studies

- Exclusive interviews with valve innovators

Available in print and digital formats.

Breaking news: Digital subscriptions now FREE!

Join our thriving community of valve professionals. Have a story to share? Your expertise could be featured next – online and in print.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”