By Ingolf Holmslet

Most industries are characterized by rapid new product development, for example regarding product quality.

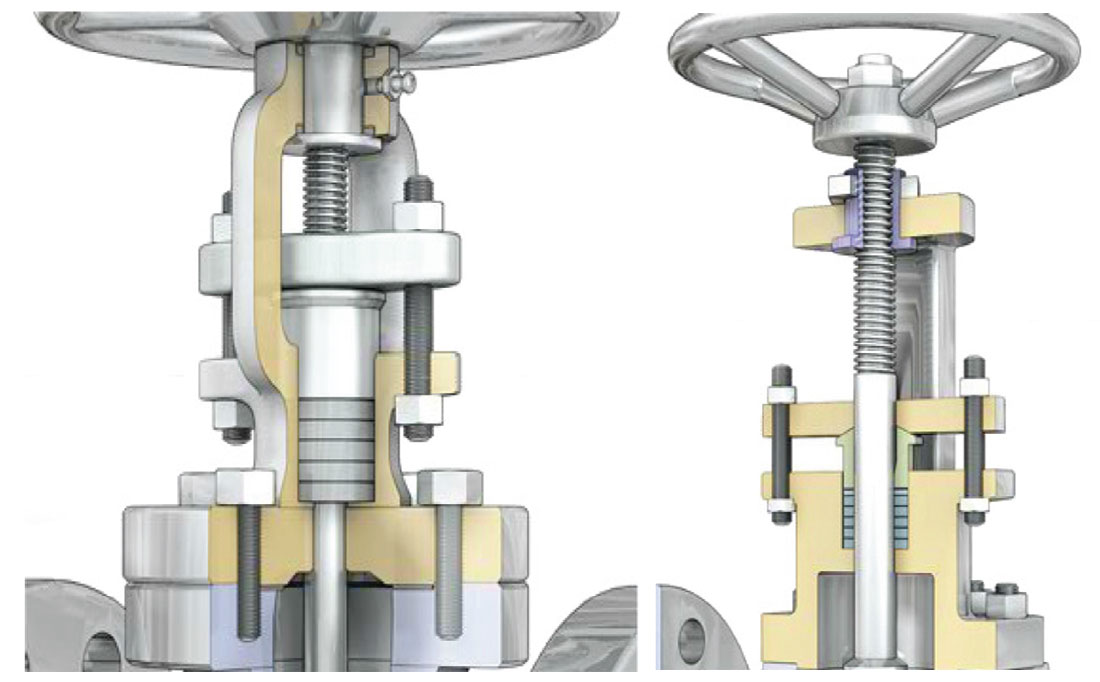

It is interesting to see whether the valve industry has done the same, taking the wedge gate and globe valve (see Figures 1 and 2 – see PDF) as examples. Recently, Téchne and yours truly designed a balanced stem construction that leads to a considerable improvement in operation.

Wedge gate valves are generally used to completely shut off fluid flow or, in the fully open position, provide full flow in a pipeline. Thus it is used either in the fully closed or fully open positions. A (wedge) gate valve consists of a valve body, seat and disc, a spindle, gland, and a wheel for operating the valve. The seat and the gate together perform the function of shutting off the flow of fluid.

A globe valve is primarily designed to stop, start and regulate flow. It is comprised of a movable disk-type element and a stationary ring seat in a generally spherical body. The seat of a globe valve is in the middle of and parallel to the pipe, and the opening in the seat is closed off with a disk or plug. Globe valves can be structured to handle flow in either direction.