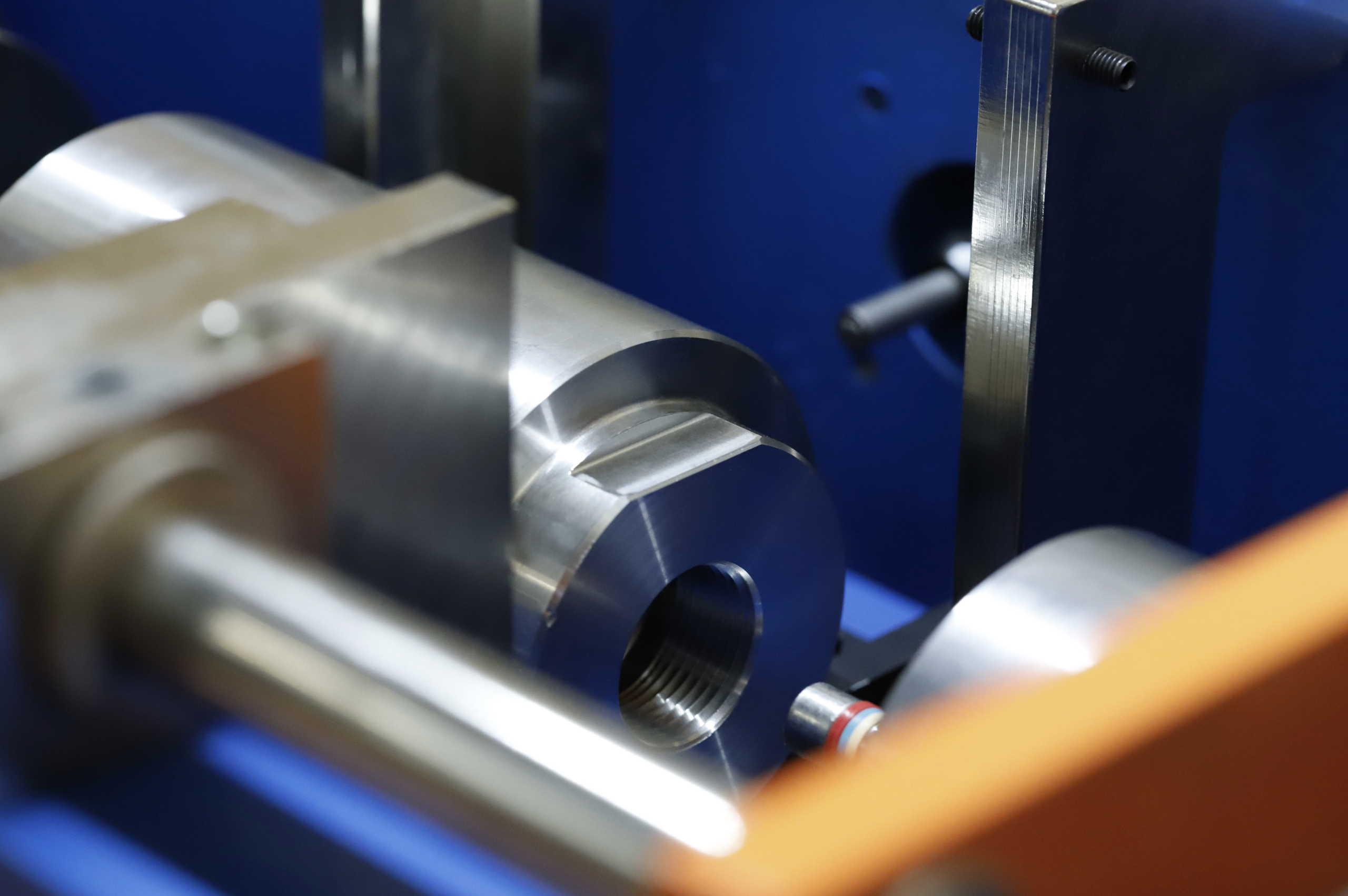

OMAL’s production plant

In Italy, the production of valves and actuators is a serious business, especially in Brescia, a hub of excellence in the sector. Italian companies set global benchmarks in quality and innovation, and OMAL S.p.A. Società Benefit is an important player in this field, constantly aiming to combine advanced technology and a long-term experience to ensure efficiency and durability in every product. Valve World got the chance to speak with Hydrogen Business Development Manager Giorgio Nicolini about OMAL’s developments in hydrogen and its new H2 INVICTUS Valve.

By Lyndsey Denton-Fray, Valve World

Whilst the 1980s might be remembered as a transformative but also at times a tumultuous era for industry, this was the beginning of OMAL, establishing itself as a supplier of high-cyclicity automation packages. Now over 40 years later, OMAL is still pushing innovation and excellence with its continued commitment to sustainability and the new H2 INVICTUS ISO 19880-3 certified valve.

In OMAL’s most recent interview with Valve World, Mr Nicolini explains how OMAL is proactively meeting the needs of the evolving hydrogen market, the importance of ensuring the environment is still put first in OMAL and how the ISO 19880-3 certification has been a game-changer in both its R&D department and market position.

Dealing with the demand of hydrogen

OMAL has been a long-term supporter in the supply chain in hydrogen. “We engineer and deliver the technology that helps companies distribute gas, but before this, you need the infrastructure in place,” explains Mr Nicolini. Whilst Mr Nicolini acknowledges that the hydrogen industry in Italy needs more investment in infrastructure, that won’t be holding back OMAL. “The use of hydrogen is a must,” states Mr Nicolini, “the demand for energy worldwide is growing, and so is the environmental impact. The advantage of using hydrogen is clear; when created by electrolysing water using green sources such as wind or solar power, then hydrogen truly is a green energy source.”

OMAL is passionate about ensuring the environment is considered in these next decisions, especially when it comes to hydrogen. “There are so many benefits to hydrogen that we appreciate. Its combustion doesn’t release carbon dioxide, it can be obtained from water through electrolysis, and it can be stored and transported at high energy density in a liquid or gaseous state,” explains Mr Nicolini. “With this in mind, it’s impossible not to consider using this gas and why we believe hydrogen is the resource capable of meeting energy needs while respecting the planet.”

Staying sustainable

Sustainability is a top priority in OMAL, which can be seen with its focus on hydrogen, but also in its implementation of the Environmental Management System in accordance with the UNI EN ISO 14001 standard in 2012. This standard is there to ensure continuous improvement of

its environmental performance with compliance of laws, strict risk analyses and further research and development solutions. “We understand the footprint of the industry we are in, so we want to address this and put the environment at the centre.”

OMAL furthered its sustainability promises in becoming a “Società Benefit” (Benefit Corporation) in 2021. Companies that achieve this status ‘combine the goal of profit with the purpose of creating a positive impact for society and the environment and operate in a transparent, responsible and sustainable way’.

“One of the purposes of investing in product and process innovation is to ensure the right balance between people and the environment. We want to build a better world for future generations,” says Mr Nicolini. “In terms of product development, it means that OMAL strives to reduce the environmental impact of its products and increase worker safety, both through product characteristics and production methodology.”

Standing out with the H2 INVICTUS

The H2 INVICTUS is the latest innovation from OMAL. “It is the result of intensive R&D work supported by a strong know-how; it is the pinnacle of our hydrogen solution,” states Mr Nicolini. “When we speak about hydrogen, high pressure generally means improved efficiency.

In fact, if we talk about hydrogen in its gaseous form, you need to compress it at high pressure if you want to store it or use it as a fuel.” Mr Nicolini states that this was the reason why it was so important to develop a new valve to accommodate these needs.

The H2 INVICTUS is a PN700 ball valve that must withstand a pressure of up to 700 bar. The valve is available from 1/8” (DN06) to 1” (DN25) with NPT end connections as standard. The valve is completely manufactured in OMAL’s own production facilities, using top-quality materials certified for hydrogen use. “All our materials are validated through a Material Assessment accredited by TÜV SÜD, meaning all materials selected to the produce the H2 INVICTUS are suitable for hydrogen services,” states Mr Nicolini.

“With over 40 years of experience in the industry, the H2 INVICTUS has been a new turning point for OMAL.”

At high pressures, hydrogen can penetrate the surface of many metals which can lead to hydrogen embrittlement. With this in mind, OMAL use a special alloy called Nitronic 50. This austenitic stainless steel is known to perform well in applications where other metals suffer from hydrogen embrittlement. “Nitronic 50 is expensive, but it’s worth it to produce a valve to the specifications and needs of the industry,” explains Mr Nicolini.

No detail is too small for OMAL. “The sealing of the valve was also carefully considered. After intense work between our engineering department and compound manufacturer, one of the main components that ensures the proper tightness of the valve was finally selected,” continues Mr Nicolini. “We are lucky to be close to one of the most important hubs of rubber compound. So, in a range of a few kilometres, we have access to a wide range of sealing solutions.”

ISO Certification

Although there are other PN700 ball valves on the market, the H2 INVICTUS is the first to be ISO 19880-3 certified by TÜV SÜD.

“This is a huge achievement for OMAL and speaks volumes for our engineering and manufacturing skills,” says Mr Nicolini. This certification is no walk in the park. The H2 INVICTUS is certified as a shut-off valve for designation up to H50 acc., meaning that the valve has to undergo a series of high-pressure tests. One of the tests was a ‘hydrogen gas pressure cycling test’, which simulated the repeated opening and closing of the valve in a hydrogen environment. The objective was to ensure that the valve could withstand more than 102,000 cycles without leakage: 100,000 cycles at room temperature, 1,000 cycles at -40°C and 1,000 cycles at +85°C.

Another test was the ‘operation test under a full pressure load’, which consisted of applying the rated pressure within 6 seconds: 10 cycles per minute, until the required 102,000 cycles were completed, with no maintenance permitted within the testing period.

A further test was the ‘worst case failure cycle test’, which simulated the worst-case scenario where the valve is closed under pressure, ensuring that it did not leak under these conditions.

Another test was the ‘hydrostatic strength test’, which applied pressure to the valve to evaluate its ability to withstand high pressures (PN x 2.4).

After this barrage of testing, the H2 INVICTUS emerged victorious. And amongst all of these pressures, the H2 INVICTUS was equipped with OMAL’s own pneumatic actuator. “We were very happy with the result,” chimes Mr Nicolini. “This certification is known for its rigorous standards and comprehensive testing. With this achievement, we demonstrate our commitment to quality and innovations, and also the choice to rely on a company like TÜV SÜD that is recognised worldwide, which enhances the trust and credibility of certified products.”

High pressure

Valves are not the only ones that need to withstand the pressures of the industry but the manufacturers too. OMAL’s endurance and perseverance in quality testing showed just how well it could manage under pressure with the prestigious ISO 19880-3 certification. “The six to seven months of certification were tough,” explains Mr Nicolini. “Our technical department faced the most significant challenges but handled it all very well. The tests that the valve had to undergo were very stringent, and the fact that the certification took seven months may seem long but was actually quite a quick time frame for this kind of testing.”

All the valves and actuators produced by OMAL, even more so with the H2 INVICTUS, are designed to work in critical applications and need to be subjected to a monitored production process. “We have implemented several quality and safety procedures inside our facilities to ensure that our valves are produced to meet the requirements set out in the ISO 19880-3,” explains Mr Nicolini. To keep up with quality expectations, OMAL have also invested in a new high-pressure test bench that will allow the company to carry out more vigorous valve production tests.

Continuing the success

After basking in the achievement of the ISO certification, OMAL is not slowing down. “The H2 INVICTUS is our starting point and the pinnacle of our movement right now,” explains Mr Nicolini. “We are focused on the developments of the market where the H2 INVICTUS plays a role and the needs and developments of the hydrogen market.”

OMAL considers contact with its customers the most important part of understanding the needs of technology. “We participate as a visitor and exhibitor at events all over the world and plan to be present at the Hydrogen Expo 2025 in Piacenza, and the Hydrogen Technology Expos in both North America and in Europe this year.”

Nor has the importance of being members of associations and networking gone unnoticed with OMAL. “Networking enables continuous exchange in information between technology providers and plant constructors,” explains Mr Nicolini. “We are members of the most important Hydrogen Association in Italy, H2IT, and through our US branch, we are also a member of the Ohio Fuel Cell and Hydrogen Coalition (OFCHC).”

Forward thinking

In looking ahead for OMAL, “anticipation is key,” claims Mr Nicolini. Whilst the ISO 19880-3 certification is not yet mandatory, Mr Nicolini expects that this will change in the future, and when or if it does, OMAL will be ready. In anticipating future changes, OMAL understand how important its R&D department is. “R&D play a crucial role in driving innovation and maintaining a competitive edge for the company.

This is the heart of the product because this is where it starts,” explains Mr Nicolini. “If you are too slow, you develop a product that is too old and behind the developments of the market. We know that taking the time but staying efficient is what will keep us competitive.” Ensuring consistency and focus was seen in developing the position of Hydrogen Business Development Manager. “We introduced my position to ensure that there was a dedicated person for the growing hydrogen market,” explains Mr Nicolini. “We want to anticipate changes and be prepared; we are confident and know where we want to be and so we are constantly working towards this.”

OMAL is clearly in a place of appreciation and excitement within its team, ensuring that moving forward customer needs, reliability and sustainability are still continuously at the heart of what OMAL does.

Dive Deeper into Valve World

Enjoyed this featured article from our April 2025 magazine? There’s much more to discover! Subscribe to Valve World Magazine and gain access to:

- Advanced industry insights

- Expert analysis and case studies

- Exclusive interviews with valve innovators

Available in print and digital formats.

Breaking news: Digital subscriptions now FREE!

Join our thriving community of valve professionals. Have a story to share? Your expertise could be featured next – online and in print.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”