In the practice of desalination, control valves are used to assist in the process of reverse osmosis. In Israel’s quest to supply the country with enough clean water, Butting has stepped in to provide Israel’s latest desalination project with their products.

By Alexandra Kist, Valve World

The drinking water supply has been a major challenge for Israel for years. The country’s natural water resources are scarce – water consumption is increasing.

With the help of five large seawater desalination plants, Israel wants to counteract this trend in the future. For the construction of the latest plant south of Tel Aviv, Butting is supplying entire mod-ules and connecting pipelines as a one-stop shop.

Prefabricated solutions

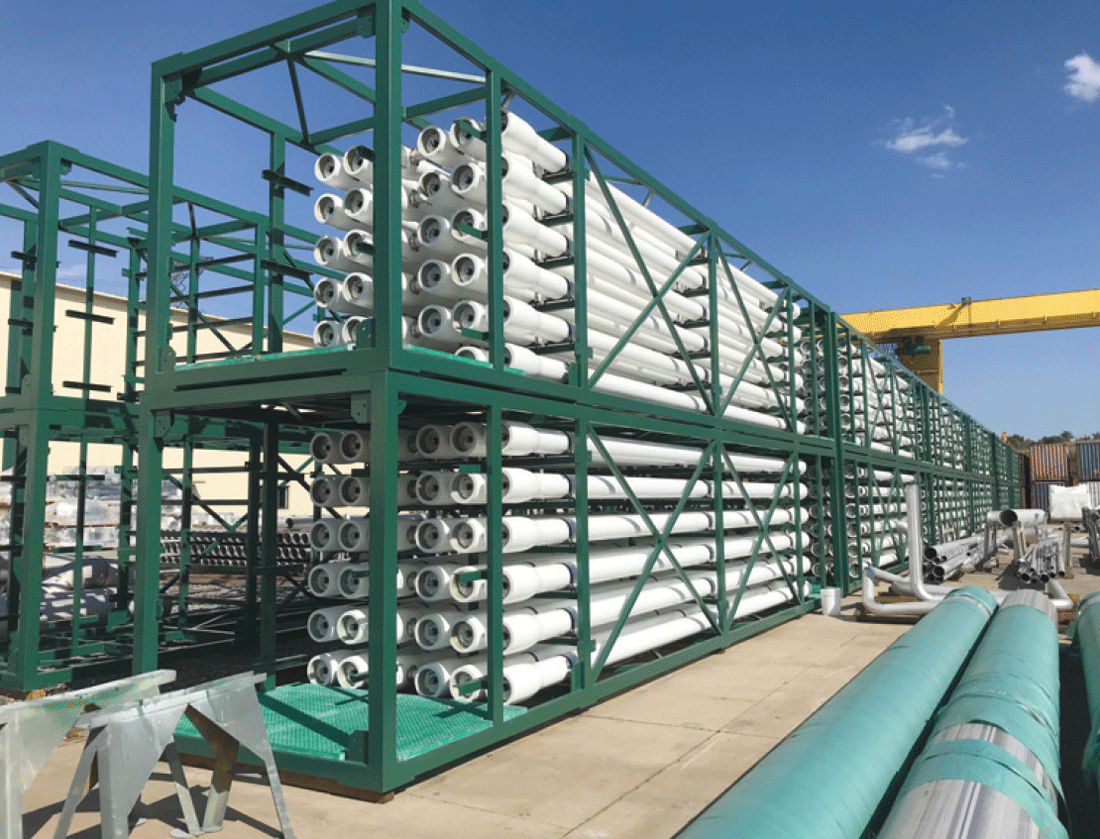

A total of 192 modules are manufactured in Butting’s factory in Tieling, which are then delivered to Israel and assembled. The piping components (ranging from 1/2” to 24”) were nearly five kilometres long and weighed 200 metric tons. The 2800 stainless steel fittings weighed close to 100 metric tons and were mainly made of superduplex. All of these were 100 percent prefabricated in Tieling, Germany. They were then non-destructively tested and mounted in the base frames in carbon-manganese steel. 3500 high-pressure filters had to be installed, aligned and inserted, and a good 900 control valves, flow meters, etc. had to be installed and wired to the more than 390 control cabinets. Butting aims to provide customers with a complete solution by assembling not only the piping components in the base frame, but also all the equipment provided, such as valves, vessels, pumps, apparatus, other components, fittings, expansion joints and electrical field devices, etc. The modules are used as a central component in the desalination and treatment process of the plant and have to withstand heavy stresses very reliably in an extremely corrosive environment. At the customer’s request, an elaborate three-coat paint finish was therefore applied to all modules. Furthermore, high demands with regards to dimensional accuracy are to be met to ensure that the materials arrive on site ready for installation, with an absolutely precise fit.

Advantages

Jens Ellermann, Managing Director of Butting in China, reports that “the advantages of Butting prefabrication pay off here: more than 95 percent of the welding seams are produced in-house by Butting. This shop welding and the pickling of whole components ensure the required seam and surface quality. In addition, non-destructive tests are already carried out on Butting’s premises. This means that pressure tests, dye-penetrant tests and X-ray testing are not required on the construction site. The result is higher quality and shorter throughput times for the benefit of our customer.”

The modules and pipelines are called off depend-ing on the construction progress.

Future plans

Commissioning of the plant is planned for 2023. Then it will get noisy in the new halls on the industrial site near the Mediterranean coast south of Tel Aviv. Large pumps will pump salt water at high pressure from the Mediterranean Sea through 5 kilometres of pipelines at a depth of 21 metres into dozens of basins. Each pressure vessel is equipped with membranes that filter out salt and minerals to produce drinking water.

The physical process is called reverse osmosis. Every year, 200 million m3 of seawater are to be treated in this way to become drinking water.

Israel’s thirst for water

Israel experiences inconsistent precipitation, which means that the amount of rainfall differs per year. The country sees a constant growth in the population and the standard of living. As a result, the various sectors bring a continuous rise in demand for water. The country currently has constructed five desalination plants over the years, located in Ashkelon (2005), Palmachim (2007), Hadera (2009), Sorek (2013) and Ashdod (2015), with total production capabilities of some 585 million m3. A second Sorek desalination plant, south of Tel-Aviv, is scheduled to be completed in 2023, and The Western Galilee water desalination plant is set to be established in 2025.

Source: gov.il