As elastomeric seals are used in extreme conditions, their performance at low temperatures is crucial. This article explores recent advancements, including ISO 5119:2023, a standardised method for evaluating low-temperature sealing capabilities.

By Ozan Devlen Chairman of ESA

Elastomeric seals are increasingly employed in demanding applications involving aggressive media, high pressures and wide temperature ranges. While compatibility is usually ensured through established testing, performance at sub-zero temperatures remains uncertain. At low temperatures, elastomers stiffen and lose resilience, reducing sealing capability. Although test methods such as torsion modulus, brittleness, compression set and temperature retraction provide useful material data, they do not directly indicate sealing performance. Proprietary tests attempt to determine minimum operating temperature, but these generally assume pressure energisation before cooling. In real applications, seals exposed to low temperatures before pressurisation may become too rigid to form an effective seal.

The aim, for the first time, is to produce an industry-agreed specification that all reputable seal suppliers can adopt, providing end-users with reliable guidance on the low-temperature operating limits of their compounds.

About the author

About the author

Ozan Devlen is a mechanical engineer M.Sc. and has been working in the sealing industry for more than 15 years. He is currently the Technology Director of Kastas¸ Sealing Technologies and serves as the Chairman of the European Sealing Association.

Effect of low temperature on material microstructure

Elastomers are polymers of long-chain molecules chemically cross-linked into a three-dimensional network. At normal operating temperatures, chain segments remain flexible but decreasing temperature restricts molecular mobility and reduces system energy. At the glass transition temperature (Tg), the material ‘freezes’ without becoming fully brittle, while further cooling promotes crystallisation and embrittlement. At this stage, determining the critical operating limit is essential.

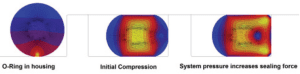

Principles of O-ring operation

The majority of elastomeric seals used in high pressure applications in the oil and gas industry are for static or pseudo-static duties and are of the squeeze type. The most common is of course the versatile O-ring, which is placed in a rectangular housing and is ‘squeezed’ by initial compression to form a seal. The sealing force applied by this initial squeeze is then augmented by the reaction of the seal to system pressure. The initial sealing force created by the compression of the seal and maintained by the residual stress that keeps the overall sealing force above system pressure. It is this balance of forces that ensures effective sealing.

Low temperature test methods

There are two types of testing for determining the low-temperature operation limits for elastomers.

- Firstly, are methods that determine changes in the properties of the elastomer material itself and then set arbitrary limits to the changes to derive an operating limit.

- Secondly, methods which are more relevant to the actual mechanism of sealing but still do not represent the usual mode of operation of low-temperature environment.

Material test method:

- Temperature Retraction (TR)

- Gehman Torsional Modulus

- Dynamic Mechanical Thermal Analysis (DMTA or DMA)

- Differential Scanning Calorimetry (DSC)

- Bend Brittle Test

- Brittleness Temperature by Impact

Sealing test method:

At the time, there was no standardized test method available that could replicate real-life operating conditions.

Several members of the ESA Elastomeric and Polymeric Seals Division (ESA EPSD) have also developed in-house low-temperature sealing test methods of varying sophistication.

Details of ESA proposed test method (ISO 5119:2023)

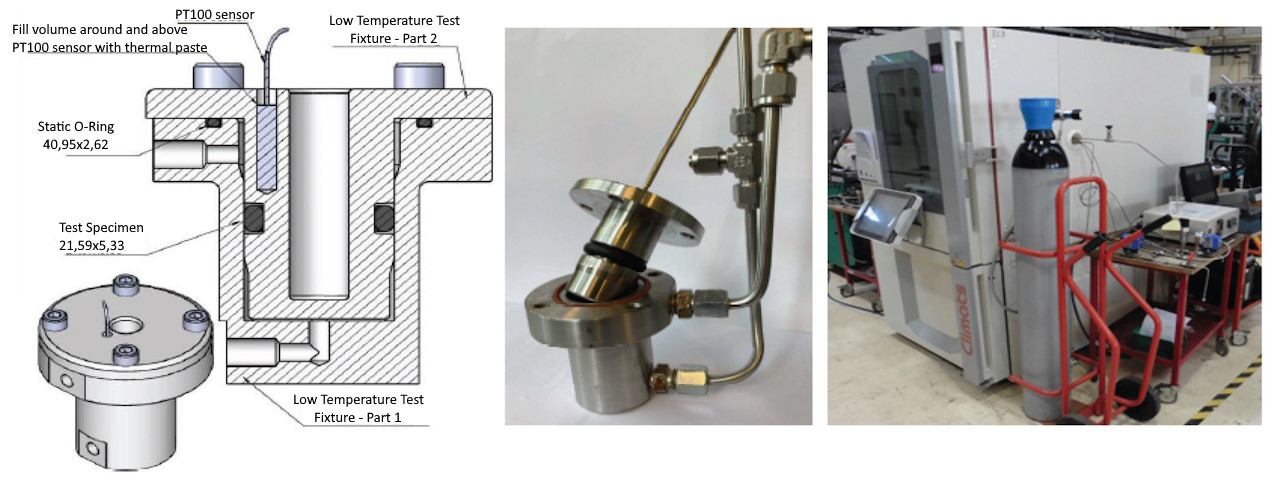

ISO 5119 establishes the methodology for testing elastomeric O-ring seals exposed to pressurised media at low temperatures. It defines the requirements for test apparatus design, standard operating parameters and the criteria for documenting and reporting test results.

Table 1: Precision data

| Material | p | m ° C |

sr ° C |

sR ° C |

Cv,ra | Cv,ra | No. of Laboratories |

| NBR | 3 | -26,93 | 0,93 | 2,11 | -0,03 | -0,08 | 5 |

| FKM | 3 | -15,73 | 0,52 | 1,69 | -0,03 | -0,11 | 5 |

p = number of measurements;

sr = repeatability standard deviation;

sR = reproducibility standard deviation;

m = mean for the level

a Cv,r and CV,R = denote relative standard deviation: that is, the standard deviation, s, divided by the mean, m, for the level.

Test conditions

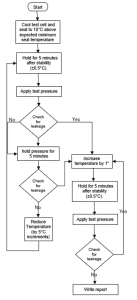

The testing procedure shall be conducted over a temperature range extending from room temperature to at least 10 °C below the anticipated minimum operating temperature of the seal. The minimum operating temperature may be determined through complementary material or functional characterisation methods, such as the Temperature Retraction Test or Differential Scanning Calorimetry (DSC). Nitrogen gas shall be employed as the test medium. The seals shall be subjected to a test pressure of 15 MPa, with an allowable tolerance of +5 % / -0 %.

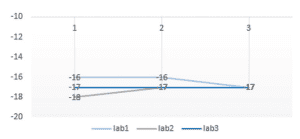

During testing, HNBR, FKM and FFKM materials were evaluated across different laboratories, and variations both between laboratories and between samples were carefully analysed. Revisions to the standard have been made to minimise variation. As an example, FFKM sample has been tested by 3 different laboratories. The results are shown in Graph 1. The variation between results is a maximum of 2 °C.

Precision calculations for repeatability and reproducibility were conducted in accordance with ISO 19983. Outliers in the original dataset were identified and treated at the 5 % and 2 % significance levels, following the procedures specified in ISO 19983.

An interlaboratory test programme (ITP) was conducted in 2021 to evaluate the low-temperature performance of O-rings. ISO 3601-1-316A-21 (59 X 5.33-N) O-ring samples from the same production batch were prepared using two elastomer compounds, NBR and FKM, which exhibit different expected minimum seal temperatures. Five laboratories participated in the ITP, located in Türkiye, France, China, and the United Kingdom (two laboratories). Fully prepared test O-rings were distributed to each laboratory for evaluation, and type 1 precision was determined.

The precision results obtained from the ITP are presented in Table 1.

The study of ESA EPSD that started in 2014, which led to the development of ISO 5119:2023, showed that the development of a testing method that gives a closer link to ‘real world’ low temperature sealing capability than existing laboratory tests is achievable.

The study resulted in an industry-agreed specification that all reputable seal suppliers can use to give end-users reliable guidance on the low-temperature operating limits of their compounds.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, October 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”