Springs are also subject to corrosion from atmospheric conditions and degradation from constant compression. Industry experts and end users are aware of an alternative to the use of springs to accomplish the fail-safe mode of operation. This is accomplished with the use of external air reservoirs to store compressed air needed to supply the required force to fail the valve to the fail-safe position. Applications for such fail-safe setup can be observed in applications for actuating large emergency shutdown valves.

With the proper pilot assembly, the reservoir would be constantly pressurized and available to

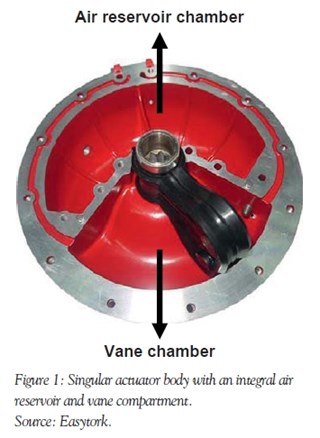

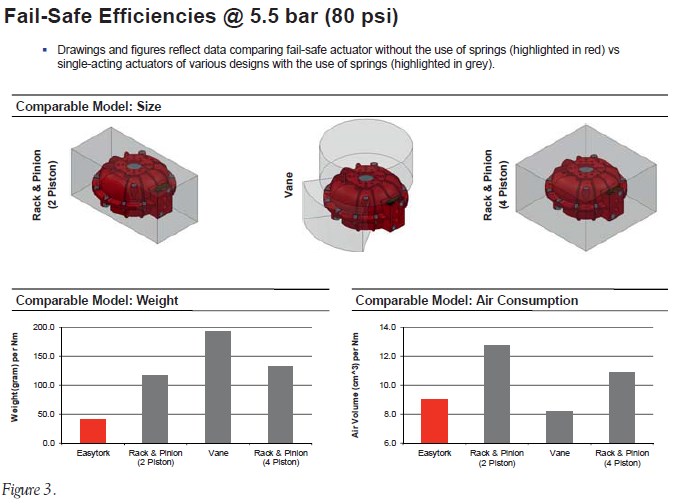

This reservoir is internal to the actuator and is sized to allow for the fail-safe operation. With the reservoir internal to the actuator, springs are not required, therefore reducing the size, weight and footprint of the actuator (Figure 3).

Traditionally, actuators can only accommodate two ISO patterns on their housing bodies, but by manipulating the space created by the air reservoir, some manufacturers have been able to add three or more flange patterns per model size for mounting to valves. This addition leads to a better valve adaptation experience, reduced valve adaptation hardware cost, and reduced model size requirements.

To read the complete article, please contact Roy van IJzendoorn for a PDF copy.