Clean, dry instrument air is critical for pneumatic instruments and actuators to work properly. In remote, dirty process control environments, like refineries, chemical plants, power plants, water treatment facilities, pulp & paper mills, or mining facilities, providing clean instrument air is challenging, costly and problematic.

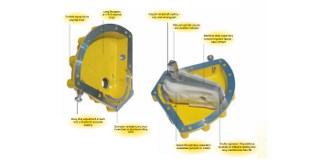

Kinetrol rotary vane actuators with their simple design, one moving part, and an elegantly engineered vane, inherently protects the actuator from bad instrument air. Kinetrol’s use of double opposed polyurethane lip seals, backed by stainless steel expanders, ensure long-term lip seal contact and effective sealing for years of maintenance free life. The vane, lip seals, and expanders actually provide a self-cleaning, or wiping, mechanism for any moisture, dirt or dust entering the interior of the actuator. In effect, the vane actuator’s design “sweeps away” the debris that will cause other actuators to fail.

Kinetrol actuators have a well-earned reputation for operating trouble-free for years in the most difficult environments. Considering their years of maintenance-free service, it’s easy to understand the significantly lower total-cost-of-ownership they deliver.