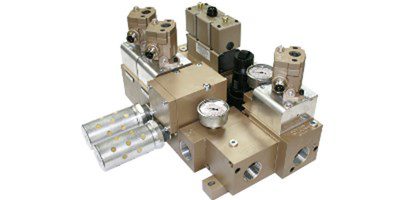

ROSS Controls® introduces its new Automatic Systems Series Valve Manifold Assemblies for Automatic Pressure Control, Press Metal Forming Applications.

The new ROSS Automatic Die Cushion Control System integrates modern air valve technology with electrical controls to monitor and control pressure in the die cushion. This new base mounted valve manifold complements the ROSS family of Automatic Systems Series assemblies for press metal forming applications.

The ROSS automatic die cushion control system is available in 1-1/2” inlet port size, units include butterfly control valve, slow raise cushion circuit, and are furnished with M12 or Brad-Harrison connectors. Fill/Dump Valves Interfaces with controls to monitor/maintain correct die cushion pressures.

Die cushion requirements can vary depending upon the tooling and parts. An automatic die cushion control assembly can quickly and easily control pressure in the cushion accumulator tank, open and close a large butterfly valve between the tank and cushion cylinder and provide a slow raise function that will fully extend the cushion cylinder without excessive, damaging force.