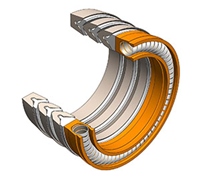

Saint-Gobain Seals has opened a new large diameter seal production facility at its Kontich, Belgium site to further improve quality and reduce lead-times significantly for large diameter, polymer OmniSeal® seals. With this new production facility, Saint-Gobain Seals aims to strengthen the service to the Energy sector for applications such as FPSO turret swivels, large engineered  valves, wind turbines, compressors and turbines. The dedicated area includes a new compression-molding press, sintering ovens, a large diameter CNC lathe, bespoke flexible forming and welding technology for Meldin® 5301 PEEK based components, special transportation racks and a large table for assembly and inspection. The equipment operates in a climatised environment to guarantee optimal dimension consistency throughout the manufacturing process until final shipping.

valves, wind turbines, compressors and turbines. The dedicated area includes a new compression-molding press, sintering ovens, a large diameter CNC lathe, bespoke flexible forming and welding technology for Meldin® 5301 PEEK based components, special transportation racks and a large table for assembly and inspection. The equipment operates in a climatised environment to guarantee optimal dimension consistency throughout the manufacturing process until final shipping.

The addition of the Kontich production facility follows Saint-Gobain Seals’ strategic plan to offer global support to meet emerging oil and gas market requirements and technology demands.

Saint-Gobain Seals manufactures critical sealing parts such as ISO 15848-1 compliant, OmniSeal® stem sealing solution, which is targeted to lower fugitive emissions within ON/OFF valves. Their high-performance sealing solutions are continually used in demanding conditions from cryogenic to 315°C (600°F), 50,000 psi, 10 to 30+ years life and strict industry specifications.