Discover how advanced pressure management techniques, particularly smart valve control systems, are revolutionising municipal water supply networks by significantly reducing water leakage while maintaining service quality.

By Guenter Oexler

Water leakage in municipal supply systems is a critical issue faced by utilities worldwide. With increasing water scarcity and the need for sustainable resource management, innovative solutions are required to minimise losses and optimise distribution networks. This article explores the concept of pressure management and the implementation of smart valve control systems as an effective strategy for leakage reduction in municipal water supply networks.

Understanding pressure management in water supply systems

Municipal water supply systems are typically designed to meet peak demand periods while maintaining a minimum pressure level at the critical point – the location with the lowest pressure in the network. This design approach often results in higher-than-necessary pressures throughout the system during off-peak hours, leading to increased water leakage.

The fundamental principle behind pressure management is simple: leakage is directly influenced by pressure. By reducing water pressure, even for part of the day, leakage can be significantly decreased. However, the relationship between pressure and leakage is complex and varies depending on the types of leaks and pipe materials present in the system.

Pressure leakage and discharge types

To understand the impact of pressure management on leakage reduction, it’s essential to consider the Fixed and Variable Area Discharges (FAVAD) theory. This theory describes two main types of leaks:

- Fixed area leaks: Typically found in iron or steel pipes, these leaks maintain a constant hole size regardless of pressure changes. In such cases, doubling the pressure results in approximately a 40% increase in leakage.

- Variable area leaks: Common in plastic or asbestos cement pipes, these leaks expand as pressure increases. Doubling the pressure can lead to a leakage increase of up to eight times the original level.

Most water supply systems contain a mixture of fixed and variable area leaks, with the proportion depending on the types of pipes in the network. This complexity highlights the importance of implementing sophisticated pressure management techniques to effectively reduce leakage.

Evolving pressure management techniques

Several pressure management techniques can be employed to reduce leakage in water supply systems. Each method has its advantages and disadvantages, and the choice depends on factors such as system requirements, available resources and technical capabilities. Let’s explore these techniques in order of increasing complexity and effectiveness:

1. Fixed outlet pressure control

This basic approach involves using a pressure reducing valve (PRV) to control the maximum pressure entering a zone.

Advantages:

- Simple installation requiring only a PRV

- Low cost with no electronic equipment needed

- Easy maintenance and operation

Disadvantage:

- Lack of flexibility to adjust pressures at different times of the day, limiting potential savings

2. Time-modulated pressure control

This method builds upon the fixed outlet system by adding a device to further reduce pressure during off-peak periods.

Advantages:

- Greater flexibility, allowing pressure reduction at specific times

- More cost-effective than flow-modulated options

- Relatively easy to set up and operate

Disadvantage:

- Does not react to real-time water demand, which can be problematic in emergencies like fires

3. Flow-modulated pressure control

This advanced technique provides greater control and flexibility than time-modulated systems.

Advantages:

- Offers more significant savings potential

- Adapts to changing water demand, ensuring adequate pressure for emergencies

Disadvantages:

- Higher cost due to more expensive electronic controllers and the need for a properly sized meter

- Requires a higher level of expertise to operate and maintain

4. Smart valve control with flow-modulated pressure management

The most advanced and effective approach, smart valve control systems combine flow-modulated pressure management with real-time data from critical points in the network

Advantages:

- Provides the ultimate level of control and maximum potential savings

- Self-adjusting system that adapts to demand fluctuations 24/7

- Can be integrated with existing SCADA or process control systems

Disadvantage:

- Most complex form of pressure control, requiring advanced technical capabilities

Smart valve control implementation

In collaboration with SAMSUN Makina Sanayi in Turkey, we conducted a simulation on test benches to demonstrate the benefits and functionality of a smart valve control system for leakage reduction. The system design incorporates two circuits with fully automated, smart control of the valves:

- Main line: Open for high demand/consumption periods

- Bypass line: Open for low demand/consumption periods

This smart system self-adjusts within given pressure parameters, continuously optimising the network’s performance regardless of demand quantity or time of day. The result is a water supply system that maintains the required pressure while minimising leakage around the clock.

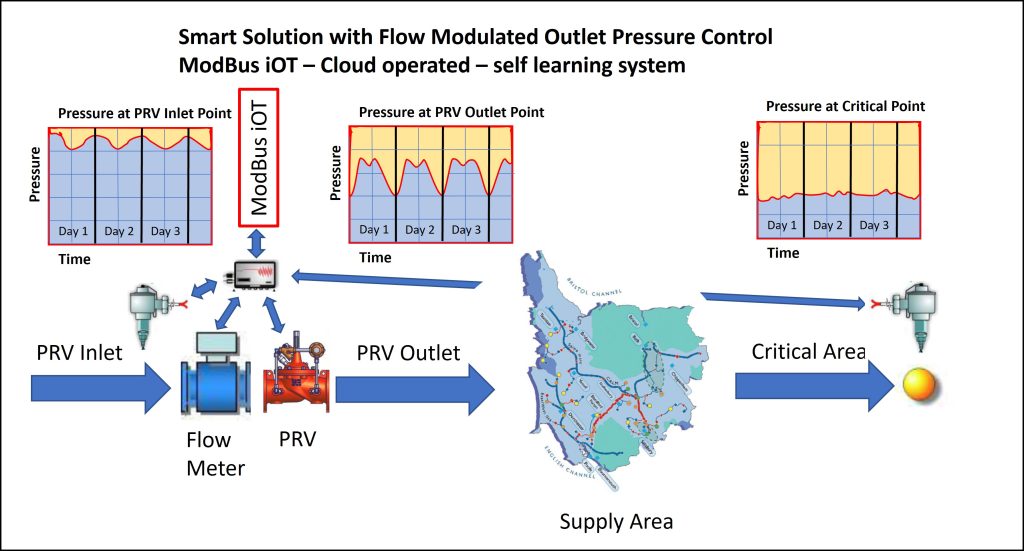

Figure 1 illustrates the concept of flow-modulated outlet pressure control with smart device integration. This sophisticated setup allows for real-time adjustment of pressure based on flow demands, ensuring optimal pressure management throughout the system.

To validate the effectiveness of this smart valve control system, we designed a comprehensive test bench setup that simulates various scenarios typical in municipal water supply networks. This experimental arrangement allowed us to measure and analyse the system’s performance under different demand conditions, providing valuable insights into its leakage reduction capabilities.

Figures 2 and 3 provide an overview of the test bench layout and equipment used in our simulation. The setup includes smart valves, flow metres, pressure sensors and control systems that mimic real-world conditions. This configuration enables us to accurately assess the performance of the smart valve control system in managing pressure and reducing leakage.

Figures 4 and 5 demonstrate the system’s ability to adapt to varying demand scenarios. During high demand periods, the main line remains open to ensure adequate flow and pressure (Figure 4). Conversely, during low demand periods, the system automatically switches to the bypass line (Figure 5), which allows for finer pressure control and maximises leakage reduction.

This adaptive approach ensures that the water supply system maintains optimal pressure levels at all times, effectively reducing leakage without compromising service quality or system responsiveness to changing demands.

Quantifiable benefits and savings

The implementation of smart valve control systems for leakage reduction offers significant benefits in terms of water conservation and cost savings. While specific calculations depend on factors such as system characteristics and local water prices, our experience shows that the return on investment (ROI) is typically achieved within months.

To assist water utilities in evaluating the potential impact of smart valve control systems, we have developed calculation data sheets in collaboration with the engineering department of SAMSUN Makina Sanayi. These tools allow for precise estimations of water savings, cost reductions and ROI for specific areas.

Conclusion

Smart valve control systems represent a significant advancement in pressure management for municipal water supply networks. By combining flow-modulated pressure control with real-time data and automated valve operation, these systems offer unparalleled flexibility and efficiency in reducing water leakage. As water scarcity becomes an increasingly pressing global issue, the adoption of such innovative technologies will play a crucial role in conserving this vital resource.

Water utilities looking to optimize their networks and reduce losses should consider implementing smart valve control systems as part of their comprehensive water management strategy. For those interested in exploring this solution further, we have developed a pre-fabricated stack system, designed to fit within a standard 40-foot container. This turnkey solution allows for easy transportation and implementation, making advanced pressure management accessible to water utilities worldwide.

About the author

Guenter Oexler brings decades of experience in valve design, process engineering, and customized solutions for water management applications worldwide. His current focus lies in optimizing municipal water supply systems through smart valve solutions, emphasizing long-term efficiency and sustainability.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, November 2024 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”