Increasing demand for thermal energy storage systems has put pressure on water utilities and private infrastructure to supply these facilities with large amounts of water. Control valves are used in water production, transmission and storage.

By Bill Moore, Cla-Val Company

Thermal energy storage (TES) systems are growing in demand due to their ability to provide cost savings, expanded cooling capacity, resiliency, and sustainability for commercial and industrial facilities. In a nutshell, TES systems store thermal energy (chilled water or hot water) for later use, which can be beneficial in managing energy supply and demand by storing excess energy produced during periods of low demand for use during peak times.

TES systems are used in centralised campuses, large hospitals, and military installations to meet increased cooling loads without investing in additional chillers, cooling towers, and pumps. Another area of increased demand for TES is large data centres, which require cooling systems to manage the significant heat generated by their IT equipment. There are over 5,300 data centres in the US, and the market is projected to grow from USD 26.67 billion in 2023 to USD 55.83 billion by 2028, with a compound annual growth rate of 15.92%.

All this demand for TES has put pressure on water utilities and private infrastructure to supply these facilities with large amounts of water. Control valves are used in water production, transmission and storage facilities. Integral to the design of a TES system, is the proper selection and configuration of valves that control flow and pressures. Selecting the proper valves is vital to the performance of a TES system.

Automatic control valves

Due to the volume and size of these systems, automatic control valves can provide many advantages over actuated ball or butterfly valves:

- Greater range and precision of modulating control: Globe-style automatic control valves have greater rangeability for flow and pressure applications. Due to the linear design, automatic control valves excel at modulating flow and maintaining tight control, providing infinite positioning capabilities. In contrast, ball and butterfly valves have a more limited control range.

- Improved resistance to cavitation: Cavitation can be an issue in some TES systems, causing valve damage, noise, and reduced efficiency. Automatic control valves are less susceptible to cavitation and can be supplied or retrofitted with anti-cavitation trim if needed.

- Simpler and more cost-effective maintenance: Automatic control valves have fewer moving parts and are generally less complex than actuated ball or butterfly valves. This makes them cheaper and easier to maintain over the long term, requiring less frequent overhauls or repairs.

- Versatility to perform multiple functions: Many automatic control valves can be configured to perform additional functions beyond just flow control, such as pressure regulation, metering, and more.

- Reliable backup functionality: Automatic control valves often incorporate backup hydraulic functionality, ensuring continued operation even during a power or control system failure.

- Customisation and upgradeability: Automatic control valves can be easily modified in the field to add new features or capabilities, without requiring a full valve replacement.

- Durability and reliability: TES systems operate continuously, so the selected valves must be durable enough to withstand extended use without frequent maintenance or replacement. Features like drip-tight closure and field-retrofittable upgrades can help ensure long-term performance.

Software Integration

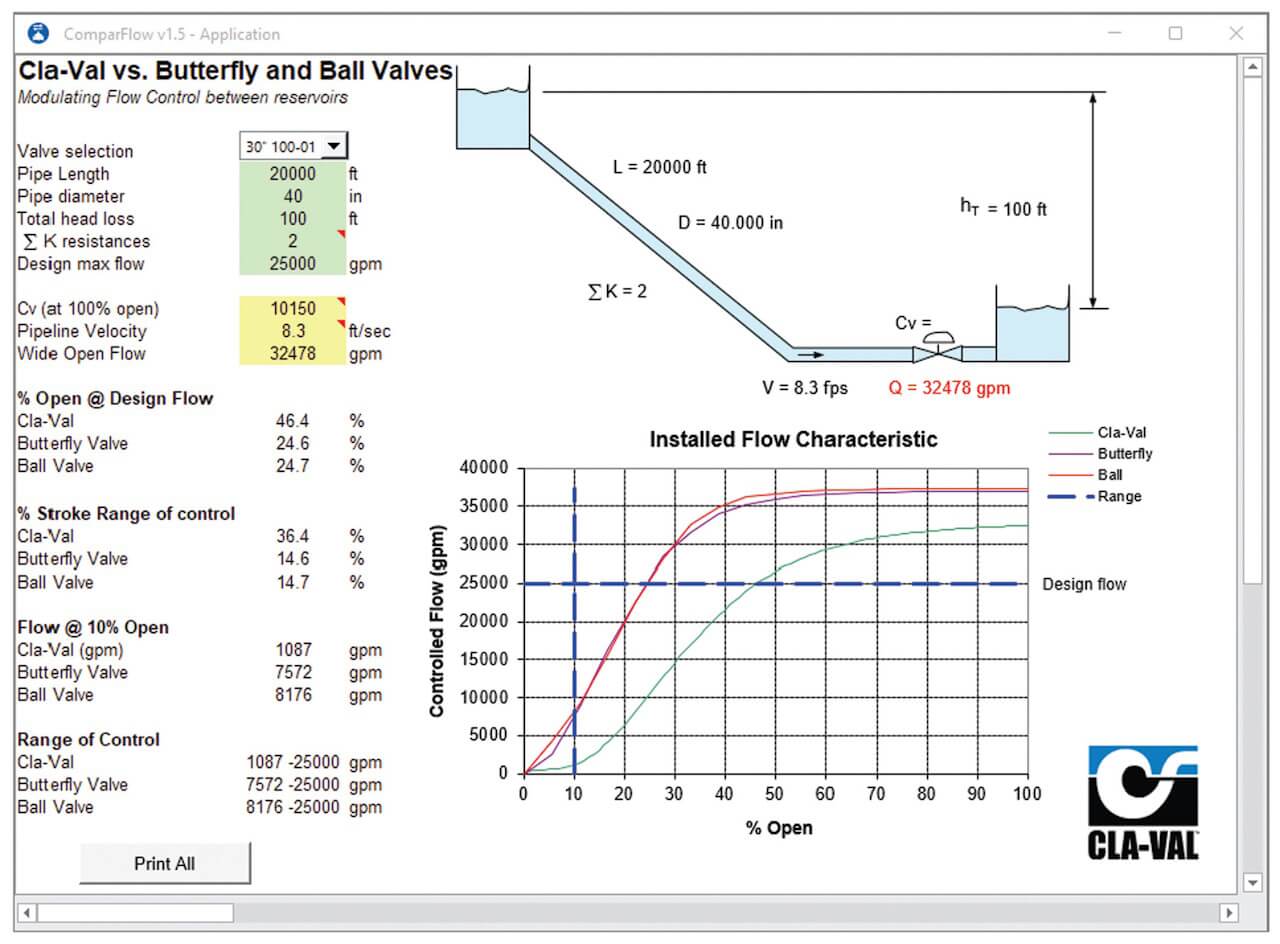

Consider valves that integrate with advanced sizing software, such as Cla-Val’s ComparFlow and Cla-cav. These software programs can model and compare the control capabilities of different valve types in a specific TES application, helping engineers make informed decisions about the most suitable valve solution.

It is also worth considering Revit drawings for implementation into the design; some manufacturers have this capability, which can save a lot of time.

Mark Gimson, Director of Marketing and International Sales says, “We have supplied hundreds of these automatic control valves for TES systems. These range in size from mega projects with Google and Microsoft to universities like Princeton, as well as commercial buildings like offices, and research facilities. We typically work with engineering firms to spec out the best configurations and can supply Revit drawings.”

TES systems contribute to the decarbonisation of energy systems, which is one of the many reasons industries and utilities are embracing this new wave, as it is yet another tool for transitioning to more sustainable energy practices. According to Allied Market Research, the global thermal energy storage market size was valued at USD20.8 billion in 2020 and is projected to reach USD51.3 billion by 2030, growing at a CAGR of 8.5% from 2021 to 2030. Mechanical, electrical, and plumbing engineers should collaborate with local valve manufacturers to harness the full potential of these TES systems. This partnership can help with the selection of an appropriate valve type tailored to the specific conditions, correct size, and configuration to meet flow demands, improving the system’s reliability and efficient performance.

About the author

About the author

Bill Moore is Eastern Regional Manager at Cla-Val Company. Bill has been with Cla-Val for over 30 years and has an in-depth knowledge of thermal energy storage systems, and works with clients to find the right valve for the right application.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, November 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”

About the author

About the author