Unique steam assist system

Several vendors offered steam converting valves with a steam atomizing design, while one vendor proposed steam converting valves with ring type spray nozzles. The company selected PRDS valves made by CIRCOR/Schroedahl. Only Schroedahl could meet the tight delivery time and offer the technical solution needed to solve the company’s requirements. With a manufacturing site in Germany and a commercial office in China, Schroedahl’s proximity to the petrochemical plant helped it understand the customer needs.

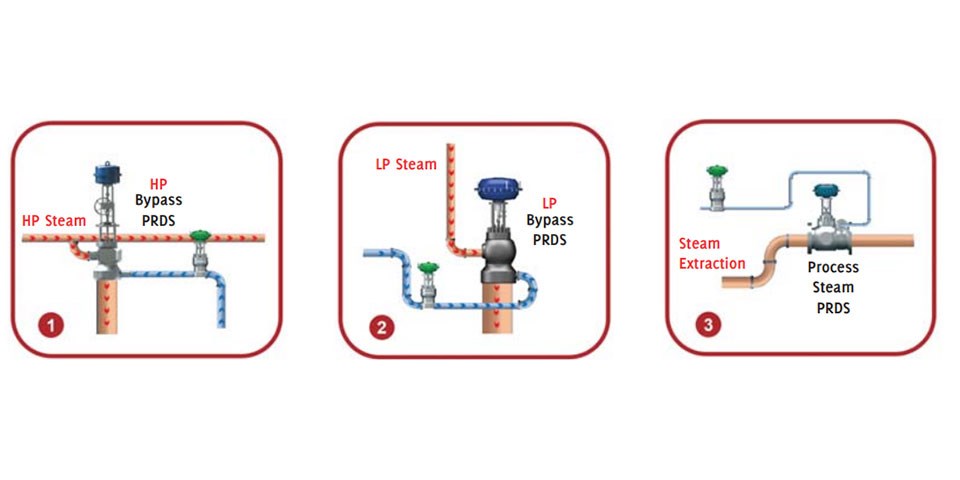

The Schroedahl solution also offered a unique steam assist system that uses high pressure steam with high kinetic energy to crack the injection water into extremely small droplets – similar to a fine fog. The system enables the plant to operate at extremely low load conditions and handle difficult start-up conditions. It also offered thermal shock risk reduction for the downstream piping system with no requirement for a downstream liner. Other options would have required an additional cooling device – which would have resulted in more cost to the customer. The PRDS selection guide shown on Figure 6 provides additional information on the available options, showing that the option selected was the best solution for high downturn duties.

Steam assist advantage

The Steam Assist-system uses high-pressure steam (high kinetic energy) to crack the water into extremely small droplets (like fog). No other system can create such a perfect cooling/evaporation.

The result is the highest rangeability; the system can operate at extreme low load conditions, handle difficult start-up conditions and provide perfect thermal shock risk reduction for the downstream piping system, with no downstream liner needed.

High level precision engineering is required to develop a valve that controls the process and achieves good performance for applications of this temperature and sizing. Developing such a valve typically requires long delivery times, often 50 weeks or more. Achieving the 24-week goal was accomplished using a novel new approach that focuses on the customer, rather than the product.

Decreased delivery times

Whereas in the past an engineering team was tasked with developing a specific valve product, the new approach uses an engineer specialist with a focus on the application-specific customer solution. Engineering teams are working on one product only and the same team works with a manufacturing expert to assemble this particular product for this particular customer.

In effect, the approach combines engineering to order with assembly to order. Achieving the required 24-week delivery time was extremely ambitious for custom valves. Normal delivery time for one DU valve is approximately 28 weeks; projects requiring several valves usually take between 32 and 40 weeks.

The new PRDS valve development strategy is based on a philosophy that PRDS valve needs are highly specialized, and products cannot be developed for standard use. Instead of working on several standard product projects, there is a focus on developing products that meet customer needs and results in dramatically decreased delivery times. In addition to the ethylene unit, the CIRCOR/ Schroedahl PRDS valve has been used at a variety of petrochemical plants in China, as well as paper factories, chemical plants, and wherever steam is produced for production.