As the European Union considers sweeping PFAS regulations, industries reliant on fluorinated sealing materials face mounting uncertainty. This article explores the implications new regulations, examining material requirements, potential alternatives and the evolving response from manufacturers and regulatory bodies alike.

By Christian Geubert, Angst+Pfister Group

PFAS, perfluorinated and polyfluorinated alkyl compounds, are on everyone’s lips due to global regulatory efforts. Industry associations warn that a sweeping PFAS ban in the EU could affect key sealing materials like FKM, FFKM, PTFE, or PVDF. These materials are used extensively as reliable and durable sealing solutions where the customer’s application requires properties that only fluorinated materials possess in this entirety. In addition to their high temperature and chemical resistance, these materials are also toxicologically harmless due to their chemical inertness, which makes them suitable for contact with regulated products in the process industry. In this combination, the food and beverage, pharmaceutical and chemical industries place particular demands on the properties and purity of the materials. As PFAS are to be withdrawn from the market precisely because of possible risks to the environment and health, it becomes clear how imprecise the collective term “PFAS” actually is for such regulation.

Due to the wide range of different compounds and applications, not all “PFAS” are the same – polymeric and non-polymeric ones differ considerably. While the environmental and health risks of some PFAS compounds are cited, there are also indispensable applications. For example, in medical technology where PFAS have a clear benefit and their use is extensively validated, such as in endoscopes, cardiac catheters, implants, stents and many more highly regulated products, alternatives are lacking. A differentiated approach is necessary in order to minimise risks without sacrificing life-saving technologies.

The European Chemicals Agency (ECHA) is still reviewing the more than 5,600 comments submitted on the planned regulation. The first statements of the responsible committees for risk assessment (RAC) and socio-economic analysis (SEAC) on various applications of PFAS emphasised persistence as the main hazard of this wide-ranging group of substances, in addition to possible additional effects of a few PFAS on the environment and human health.

So far, however, the committees have not yet addressed the applications of sealing technology; food producers, machine manufacturers and seal manufacturers are facing the uncertain situation by examining all options between the hope of a complete or partial exemption of polymers from the planned regulation due to their inertness and the feared ban of all PFAS and also polymeric fluorinated materials in the most comprehensive manner. In the latter case, once the regulation comes into force, these applications would only be equipped with significantly shorter-lived sealing materials, if at all, with all conceivable consequences.

The ECHA communication of 20 November 2024 now acknowledges the extensive efforts of industry and associations and specifically recognises the unsurpassed benefits of fluoropolymers in sealing technology. This application in particular – with sealing tasks in consumer, professional and industrial applications as gaskets, pipe linings, flat gaskets and valve components – is explicitly mentioned as a new, previously unidentified use of PFAS.

The notification also opens up new possibilities with regard to the further course of proceedings. For example, alternatives to bans will also be discussed as part of the further procedure, which was not previously envisaged.

ECHA’s update is promising, but further evaluation is essential. Possible alternatives for the respective application with the respective parameters must still be sought and evaluated in all aspects, if at all possible. Food producers, machine builders and seal manufacturers are also hoping that the two committees, RAC and SEAC, will be able to give them an indication of which path to take. It remains to be seen whether – as criticised in Regulation (EU) No. 10/2011 – the focus will be on the more consumer-oriented packaging issues with moderate conditions

and long-term contact, or whether sufficient consideration will also be given to the food industry applications, which tend to have shorter, more aggressive process conditions and therefore require completely different mechanical, thermal and chemical assessments.

A comprehensive examination of both aspects would be important in order to reduce the uncertainties of the entire food industry and its suppliers from the mechanical engineering sector. In this respect, the food industry must be seen as a forerunner of the other branches of the process industry, as many of the mechanical engineering companies concerned also supply the other branches, albeit in varying proportions.

The manufacturers of fluorinated polymers are now reacting to this unclear situation and are reviewing their product ranges and production processes, improving them to avoid critical short-chain PFAS, especially fluorinated surfactants with water-soluble properties, or phasing out the production of fluorinated materials completely.

As downstream users of polymer PFAS, compound manufacturers are now facing up to the challenge of a reduced supply chain that can also change at very short notice, reviewing their materials portfolio and developing new materials in order to be able to offer their customers all the options, regardless of the path that global regulation may take in the coming years.

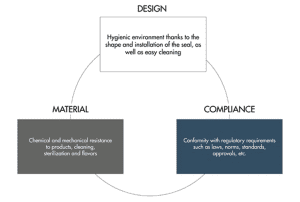

The Three Aspects of Seal Selection for Food, Beverage and Pharmaceutical

On the one hand, the chemical resistance of the elastomer is essential in addition to the mechanical resistance in order to obtain seals that are resistant to aggressive products with a wide variety of ingredients. Aggressive products do not necessarily have to be hazardous substances such as the cleaning chemicals in the form of heated alkalis, acids, oxidizing sterilization media or steam that are essential in the food and beverage industry. In fact, beverages with flavour mixtures or foods with solid ingredients such as nuts, seeds or fruit pulp can also pose a major challenge for sealing technology.

On the one hand, the chemical resistance of the elastomer is essential in addition to the mechanical resistance in order to obtain seals that are resistant to aggressive products with a wide variety of ingredients. Aggressive products do not necessarily have to be hazardous substances such as the cleaning chemicals in the form of heated alkalis, acids, oxidizing sterilization media or steam that are essential in the food and beverage industry. In fact, beverages with flavour mixtures or foods with solid ingredients such as nuts, seeds or fruit pulp can also pose a major challenge for sealing technology.

On the other hand, the material must meet the necessary legal requirements for contact with food. Globally harmonizing compliance helps reduce material variants. However, differing legal standards – like 21 CFR 177.2600 (FDA), China’s GB regulations, or Germany’s BfR recommendations – mean materials must satisfy diverse safety expectations without mutual recognition.

Ultimately, once the above material requirements have been met, the final geometry must also be suitable for use as a seal in a regulated industry such as the food and beverage industry, which is summarised under the keyword “hygienic design”. Seals should not represent a design weakness from a hygienic point of view and should not, for example, unduly hinder the cleanability of the system.

The avoidance of incorrect installation or over-pressing should also be prevented by the design; aspects that can easily be taken into account if the gasket supplier is involved at an early stage.

The currently looming regulation on PFAS now threatens this first aspect of material durability. Fluorine-containing polymers are unique in their thermal and chemical resistance and cannot be replaced by other materials, even if other materials can be used in individual cases. However, this depends on the process conditions of this individual case, so that the original reason for using fluorine-containing polymer materials as a universal material for (almost) all applications is no longer given and several variants may have to be selected depending on the product and cleaning conditions, temperature or load case.

New FKM Materials without Fluorine Surfactants

Angst+Pfister is developing new peroxide cross-linked FKM as a successor to the materials PERTEC® CIP FKM 75.501-04 and PERTEC® UP FKM 70.501-07, which are used in the food industry, among others, as so-called NFS versions (non-fluoro-surfactant) in the hoped-for case of an exemption of polymer materials from the existing regulations. The background to this is that the polymer manufacturers also used water-soluble fluorosurfactants for peroxide-crosslinked FKM. New processes from the polymer manufacturers do not require these substances but make a polymer replacement necessary, making this material development unavoidable for all peroxide cross-linked FKM from all gasket manufacturers. Angst+Pfister’s new materials are expected to have almost the same properties as their predecessors due to their great similarity.

In the hoped-for case of an exemption of polymeric PFAS from the regulations, the proven FKM material HITEC® FKM 75.16-04, for example, would remain available, which as a bisphenol-crosslinked material is fortunately not affected by the described issue of fluorosurfactants.

Taking into account the currently estimated time periods until a regulation comes into force not before 2028, but perhaps not until 2030 or later, there is still sufficient time for the usual maintenance cycles of one or two years in many cases and there is no need for a “headlong” changeover, even if a complete ban on fluorinated polymers will have a significant impact on the expected maintenance cycles and the safety of machines and systems. Nevertheless, it now makes sense to examine materials that are not affected by the planned PFAS regulation in order to be prepared for a complete ban. On the one hand, this is the only way to assess the changes to be expected for the worst-case scenario in each individual case; and on the other hand, to derive the necessary steps for design and product management, such as a greater number of variants, a design change for faster replacement or even measures to reduce potential damage in the event of an expected leak.

Exploring PFAS-Free Materials: Angst+Pfister’s EPDM, VMQ, and HNBR Solutions for Food, Beverage and Pharmaceutical Industries

The materials available from Angst+Pfister’s material portfolio for these applications include, among many others, materials from the EPDM and VMQ groups. While HITEC® DW EPDM 70.503 00 was originally optimised for contact with drinking water and designed for durability in this application, it also meets numerous additional approvals for the food industry and even the pharmaceutical sector (see illustration).

The materials available from Angst+Pfister’s material portfolio for these applications include, among many others, materials from the EPDM and VMQ groups. While HITEC® DW EPDM 70.503 00 was originally optimised for contact with drinking water and designed for durability in this application, it also meets numerous additional approvals for the food industry and even the pharmaceutical sector (see illustration).

On the other hand, PERTEC® UP EPDM 70.503 04 is tailored for ultra-pure applications and additionally complies with Chinese and French food safety approvals. A harder version of this material, PERTEC® UP EPDM 80.503 01, is also available. Alternatively, PERTEC® UP VMQ 70.501-01 offers better fat resistance than EPDM, with broad international approvals.

For softer solutions, the variant PERTEC® UP VMQ 50.501-02 is available. When comparing these materials directly with FKM materials, there are naturally material-specific limitations: EPDM shows reduced performance with high-fat content, and VMQ has lower resistance to steam sterilisation processes.

To complement this range of PFAS-free materials, Angst+Pfister developed a next-generation HNBR, aiming to reintroduce this material class – largely replaced by FKM materials since the mid-2010s – using modern technology.

Summary and Conclusion

The currently unclear situation regarding the planned regulation of all PFAS is unsettling food producers, machine manufacturers, seal manufacturers and their suppliers.

A rapid improvement of this situation through clear regulations is not yet in sight, even though the latest communication from the ECHA recognises the importance of fluoropolymers for applications in the sealing industry. Associations are seeking clarification and, in particular, a complete exemption of polymeric PFAS from the planned regulations, as they are safe to manufacture, use and dispose of. In fact, in many sealing applications, fluoropolymers often have no equal, and alternatives may shorten service life and increase failure risk. To prepare for potential regulation, users should consult gasket suppliers to evaluate current fluorinated options and viable alternatives.

Dive Deeper into Valve World

Enjoyed this featured article from our September 2025 magazine? There’s much more to discover! Subscribe to Valve World Magazine and gain access to:

Advanced industry insights

Expert analysis and case studies

Exclusive interviews with valve innovators

Available in print and digital formats.

Breaking news: Digital subscriptions now FREE!

Join our thriving community of valve professionals. Have a story to share? Your expertise could be featured next – online and in print.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”