___

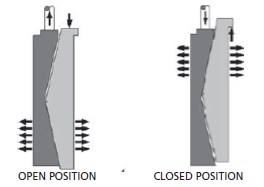

Due to the angle between the gate and segment a sliding movement will push the gate and segment towards the seat to achieve sealability. During travelling for open and closed positions the gate slides over the segment due to the design of the angle and cam arrangement (control arm or lever lock arm) which holds the two parts together to maintain a tight seal.

Full bore is quite achievable in these valves, a feature which makes this valve most suitable for the use of a pig launcher or scraper. Full bore also allows these valves to operate with negligible pressure drop. The valves have drain and relief arrangements (with expanding gate feature), so a gas tight shut off feature is also quite achievable.

The weight of segments can also be enormous (many tonnes) and for higher sizes and ratings this can cause valve stems to bend. A last resort may be modification in the design of valve body altogether, and to consider supporting the gate/segment with an additional arrangement as this will require space between gate/segment and valve body. Such a modification incurs additional cost, schedule and risk implications when running projects, and may not be feasible at all.

The API 600 2015 edition mentions that the design of normal gate valves should ensure correct alignment of gate and stem for all orientations. For sizes DN 650 and above, as a minimum, wedge guides and body guides are hard-faced to allow the valve to take any orientation. But then it also talks about manufacturers providing in their installation and operational manual any limitations as a result of stem and valve orientation. API 6D does not specifically address this issue and dictates for installation and operational manual for valves. Designers should discuss the issue extensively when obtaining technical clarifications from manufacturers, rather than waiting for the installation and operational manual after the purchase order.