The revolutionary Severn OCT® technology introduces hybrid sealing technology to the Triple Offset Valve (TOV), with interchangeable seals and dual anti-blowout design, ensuring the TOV meets the most stringent of specifications. When comparing Triple Offset valves (TOV) to Double Offset valves, on paper the valves can appear to be very similar. However, there is a distinct advantage to using the more technical offering that comes with a TOV. The conical shape of the disc and seal offers repeatable sealing and extended service life. Severn’s patented OCT® technology enhances the traditional TOV, and these enhancements will be explored further in the article.

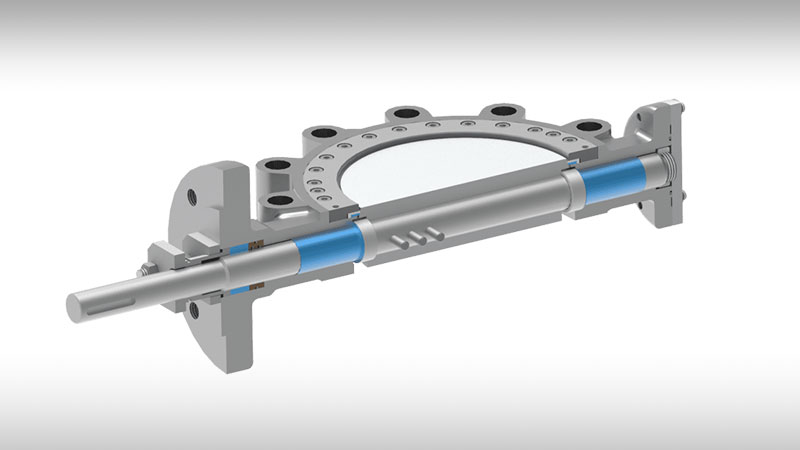

The Oblique Cone Technology (OCT®) moves away from the traditional elliptical shape and provides circular sealing geometry, allowing proven Double Offset sealing knowledge to be incorporated into the TOV. It can utilise trims that are traditionally found on double offset valves, such as an anti-cavitation trim, making the TOV the ultimate valve for both isolation and control application specifications.

The TOV is self-compensating for wear, meaning consistent sealing performance is achieved time after time. The camming action of the third offset reduces seal wear by minimising seal contact. The disc and seal only contact each other in the last 1-2° of operation, not only minimising wear but also reducing friction. Comparing this to a Double Offset valve, which contacts for 10° of operation.