Turkmenhimiya, a state-owned chemical company is currently building the country’s largest ammonia and urea plant. The required feedstock for the fertiliser project, which integrates an ammonia plant and a urea plant, will be sourced from the country’s abundant natural gas reserves. Upon the commissioning of the facility next year it will be the largest fertilizer production factory in the country with a daily production capacity of 3,500 tons of granule urea and 2,000 ammoniac, most of which will be exported through the port of Turkmenbashi.

The products from the project will be primarily exported, enhancing the country’s natural gas products, as well as expanding and diversifying its exports and sales. The construction of the plant, which occupies an area of 60 hectares, began in December 2014 under an agreement signed by the state-owned Turkmenkhimiya with a consortium consisting of the Japanese company Mitsubishi Corporation and Turkish Gap Insaat, part of Chalyk Holding. The plant is located just outside Garabogaz and is estimated to cost $1,350 billion. It currently employs more than 3,000 employees, of which 2,700 are citizens of Turkmenistan.

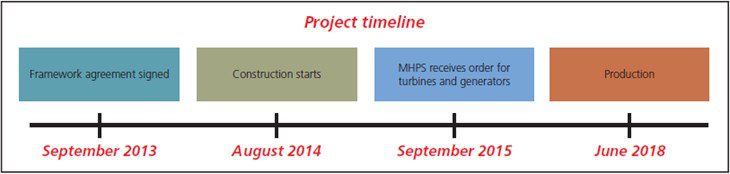

Turkish company Gap İnsaat will provide construction of road, gas, energy and communication connections of the system as well as the 2.5-km conveyor system and road between the facility and the Bekdas¸ Harbour Pier to where the product will be transferred. The Japanese Mitsubishi Corporation and Mitsubishi Heavy Industries will jointly undertake responsibility for the installation, licensing of project production units, management of supply process, equipment supply with cutting edge technology and export of products to be manufactured to global markets. Gap İnsaat will deliver the basic engineering services as well as the entire construction work and supply, assembly and commissioning of materials accordingly. MHPS will supply two sets of its natural gas-fired H-25 gas turbine and generator. The power generation system is scheduled to go on-stream in June 2018. The order marks the first H-25 gas turbine to be supplied to Turkmenistan by MHPS. The H-25 is a high-reliability, low- maintenance, heavy-duty gas turbine. Since receipt of the order for the very first unit in 1987, to date more than 170 units have been ordered by customers in Japan and other countries.

MHI has completed numerous such plants around the world. Recent large-scale fertilizer plant projects ordered include an ammonia/urea plant in Algeria in 2008, an ammonia/urea/methanol concurrent production plant in the Republic of Tatarstan in 2010, an ammonia/urea plant in Malaysia in 2011, and an ammonia plant in Russia in 2013. Going forward, MHI will further strengthen its marketing activities to secure successive orders for synthesis gas and petrochemical plant projects, and enhance its presence in the fields of fertilizer production and fertilizer plant development. GAP Insaat, part of Turkey’s largest conglomerate Calik Holding, is undertaking all construction works including detail engineering and design. Superlit is supplying fibreglass- reinforced polyester (GRP) pipes for the cooling water system and will further supervise the submarine and onshore installation of the pipes. Sarplast is supplying the associated fittings, flanges and spools.

Haldor Topsoe to help minimise environmental impact

Haldor Topsoe is responsible for the engineering design of the ammonia plant with special emphasis on minimizing the environmental impact from production by featuring a SCR (Selective Catalytic Reduction) DeNOx unit which can treat the flue gas from the facility reducing NOx pollution. Besides engineering design and licensing, the delivery from Haldor Topsoe also includes proprietary hardware related to the ammonia process technology as well as catalysts. The award of the contract is a continuation of a successful collaboration between Mitsubishi Heavy Industries and Haldor Topsoe that currently have three other ammonia related projects under construction.

Haldor Topsoe has also won another contract in Turkmenistan – on 26th August 2016 Haldor Topsoe announced they won a contract to construct a major focused on the conversion of natural gas into synthetic gasoline. This plant will be based on Haldor Topsoe’s TIGAS™ (Topsoe Improved Gasoline Synthesis) technology and will become the first full scale large commercial facility in the world using this technology.

Application requirements in urea plants

In the fertiliser industry and especially the urea industry, components such as safety valves have to withstand severe production conditions like high pressures, high temperatures and corrosive media. High on-stream times are main targets of plant operators. Reliable technologies, equipment and machinery are a pre- requisite to guarantee the expected plant capabilities. Safety valves are used for protection of the main sections in urea plants like ammonia and CO2 supply, synthesis section, re-circulation section and also for secondary steam and cooling water supply.

In urea high pressure synthesis sections, CO2 and NH3 react to carbamate which is an intermediate in the Urea production. Carbamate is highly corrosive and can easily crystallise. These major medium properties have to be considered for a proper safety valve design and the correct selection of materials of construction. Carbamate requires the use of special stainless steels. Special stainless steel grades such as 316L urea grade or 1.4466 – UNS S31050 are used for the highly corrosive carbamate at high pressures (up to 200 bar / 2900 psig) and high temperatures (up to 200°C / 392°F). (Source: LESER)

Valves used in fertiliser plants

The various valves used in fertiliser plants include: diaphragm, PTFE sleeved plug, gate, globe, check (lift, swing, wafer, non-slam, dual-plate), ball, pinch and on/off block or isolation valves. UK Process Valves has supplied hard rubber lined diaphragm valves to the Garabogaz project.