In the oil and gas industry’s midstream and downstream sectors, valve automation is crucial for efficient, safe and reliable operations. Universal couplings play a key role in linking actuators to valves, offering flexibility and compatibility across various valve types and actuator models. This article explores the benefits, features and applications of universal couplings in enhancing automation systems.

By Donald Clark, GCISPRO

In the world of industrial automation, particularly in the midstream and downstream sectors of the oil and gas industry, efficiency, safety and reliability are of paramount importance. Valve automation plays a crucial role in regulating flow, pressure and other vital parameters in pipelines, storage tanks and processing units. In these applications, the seamless integration of valves with automation systems ensures smooth operations, reduces downtime and enhances control over critical processes.

One of the most essential components in valve automation is the coupling system that links the actuator with the valve. A universal coupling for valve automation offers a flexible and versatile solution, allowing different valve types and actuator models to be paired together regardless of manufacturer specifications or designs. This article explores the significance of universal couplings in valve automation, their benefits, key technical features and their application in midstream and downstream facilities.

The importance of valve automation in midstream and downstream facilities

In the midstream and downstream sectors, valves control the flow of crude oil, natural gas and refined products across vast pipelines and in storage tanks. These facilities require a high degree of automation to optimise their operations, improve safety and minimise environmental impact. In pipeline systems, valves are used to control the flow of product and prevent spills or leaks. In refineries and chemical plants, they manage the flow of raw materials and finished products, ensuring the smooth operation of complex processing units.

Automating these valves allows operators to control them remotely, often from a central control room, and respond to changes in conditions instantly. Automated valves can open or close based on pre-set parameters or control signals from supervisory control and data acquisition (SCADA) systems. This automated control minimises human error, increases precision and allows for quick responses to system failures or anomalies.

As facilities become more complex and diverse in their operations, it is critical that valve automation solutions be adaptable, scalable and able to work across different valve types and actuator systems.

The role of universal couplings in valve automation

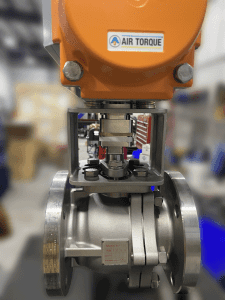

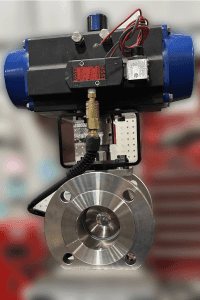

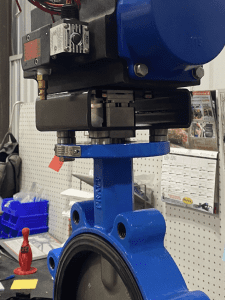

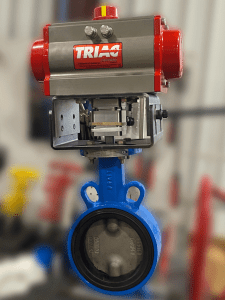

A universal coupling is a mechanical interface that connects the actuator to the valve in an automated system. Actuators, typically pneumatic, electric or hydraulic, are used to open or close the valve. The coupling serves as the intermediary, ensuring that the motion generated by the actuator is properly transmitted to the valve, causing it to move as intended.

In traditional valve automation, each type of actuator and valve may have its own specific connection standard, making it necessary to use custom couplings for each combination. This can lead to inefficiencies, increased inventory costs and compatibility issues when trying to pair actuators with valves from different manufacturers. A universal coupling solves these challenges by providing a standardised connection that works with a wide range of valve types and actuator models.

The role of universal couplings in valve automation

Key benefits of universal couplings in valve automation

1. Increased flexibility

One of the primary advantages of a universal coupling is its versatility. In facilities where different types of valves are used for various processes, a universal coupling ensures that the automation system can be easily adapted to work with all of them. Whether the valve is a ball valve, gate valve or globe valve, the same coupling can be used to integrate different actuator types, reducing the need for specialised couplings for each combination.

2. Reduced inventory and maintenance costs

By using a universal coupling, operators can significantly reduce the number of spare parts they need to keep in stock. With fewer specific components required for valve-actuator connections, facilities can streamline their inventory and lower maintenance costs. This simplification also makes it easier for maintenance teams to perform repairs, as they are not required to search for rare or custom components when a part needs to be replaced.

3. Enhanced reliability and performance

A universal coupling is typically designed to provide reliable, durable connections, ensuring that the actuator and valve work together as intended over the long term. This reliability is especially critical in midstream and downstream facilities, where system downtime can result in significant financial losses and safety hazards. Universal couplings are engineered to withstand the extreme pressures, temperatures and other harsh conditions typical of these environments, ensuring stable performance even in demanding applications.

4. Standardisation across multiple manufacturers

The ability to standardize coupling interfaces across different manufacturers is another major advantage. Facilities often use a mix of valves and actuators from different suppliers, and without a universal coupling, this could create compatibility issues. A universal coupling simplifies the process of integrating these components and ensures smooth communication between the actuator and valve, regardless of their brand or design.

5. Reduced installation time and costs

With fewer components to source and match, installation times are shortened, and the overall cost of installation is reduced. Installers no longer need to spend time customizing couplings or performing complex adjustments to make different components work together. As a result, automation systems can be deployed more quickly and efficiently, allowing facilities to achieve operational readiness sooner.

Technical features of universal couplings

To ensure the seamless integration of actuators and valves, universal couplings must possess certain technical features that enable them to function effectively across a wide range of equipment. Some of the key characteristics of these couplings include:

1. Adjustable mounting interfaces

Universal couplings often feature adjustable mounting interfaces that can accommodate different valve designs and actuator sizes and manufacturers. These couplings are typically designed to be compatible with a variety of flange patterns, shaft diameters, and attachment methods, making them suitable for a wide array of applications.

2. Torque transmission capability

A universal coupling must be capable of transmitting sufficient torque to operate the valve with precision. The coupling must be able to withstand the force generated by the actuator without slipping or degrading. This is particularly important in high-pressure systems, where the torque requirements can be substantial.

3. Corrosion and wear resistance

Given the harsh conditions in which midstream and downstream facilities operate, a universal coupling is typically made from corrosion-resistant materials, such as stainless steel or specialized alloys. These materials ensure that the coupling can endure exposure to chemicals, extreme temperatures, and abrasive materials, reducing the risk of failure and extending its service life.

Applications

In a midstream and downstream facility, a universal coupling is used in a variety of valve automation applications, from pipelines and compressor stations to storage tanks and refineries. The adaptability makes it suitable for a wide range of processes, including:

1. Pipeline transportation

In pipeline systems, valves are used to control the flow of oil, gas, and other liquids over long distances. Automated valve systems enable operators to monitor and adjust the flow remotely, ensuring that product is transported efficiently and safely. Universal couplings help integrate actuators with different valve types, ensuring that the entire system works seamlessly.

2. Compressor stations

Compressor stations are critical in maintaining pressure within a pipeline, ensuring that product flows smoothly even over long distances. Automated valves in these stations control the release of pressure or the isolation of specific sections of the pipeline. Universal couplings are essential in these systems, allowing different types of valves and actuators to be used interchangeably.

3. Refineries and chemical plants

Refineries and chemical plants require precise control over the flow of raw materials and refined products. Automated valves are used extensively in processes such as distillation, cracking, and catalytic reforming. A universal coupling allows for the integration of actuators and valves from different manufacturers, helping to optimize operations and improve system flexibility.

4. Storage facilities

In storage tanks, automated valves control the flow of liquids into and out of the tanks, maintaining the proper levels and preventing overflows or contamination. Universal couplings make it easy to connect actuators to different valve types used in these applications, ensuring reliable operation and reducing the need for specialized components.

Conclusion

In the midstream and downstream sectors of the oil and gas industry, efficient and reliable valve automation is crucial for ensuring smooth operations, maintaining safety, and minimizing downtime. A universal coupling will provide a flexible, cost-effective solution for linking actuators and valves across a range of different systems, sizes and manufacturers by enabling compatibility between various valve types and actuator models, a universal coupling reduces the need for custom components, simplifies maintenance, and enhances the overall reliability of automated systems.

As the complexity of industrial facilities continues to grow, the ability to standardize coupling interfaces and integrate a wide variety of equipment will be increasingly important. A universal coupling would represent a key innovation in valve automation, offering significant benefits in terms of cost savings, operational flexibility, and long-term reliability, all of which are critical to the success of midstream and downstream operations in the oil and gas industry.

About the author

Donald Clark has built a distinguished career in the valve and automation industry over the course of 33 years. In 2013, he conceptualised the idea for the ‘Universal Coupling’, an innovative solution that he believes will later transform the industry of automation assembly. In 2021, Donald partnered with Ian Brown, a mechanical engineering graduate from the University of North Texas, to bring the Universal Coupling to life. Ian brought a wealth of experience across automotive, aerospace and automation sectors. Together, they founded B&C Innovations LLC in January 2023, to deliver cutting-edge solutions that truly make a difference for their customers. Their partnership exemplifies a commitment to innovation, problem-solving and a forward-thinking approach to the ever-evolving valve and automation industry. Contact dclark@GCISPRO. com for additional information.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, May 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”