During the refurbishment of valves, two primary sealing solutions are typically employed. What are the advantages and disadvantages of packing sets vs packing lengths?

By Ralf Vogel, ESA

Fugitive emissions, which refer to the unintentional release of gases or liquids from pressurised systems, pose a significant challenge in industrial settings, especially within the oil and gas, chemical, and power generation industries. Effective sealing of valves is essential for managing these emissions. During the refurbishment of valves in site revisions, two primary sealing solutions are typically employed. What are there advantages and disadvantages?

Valve packing sets

Valve packing sets consist of pre-cut and pre-measured rings of packing material tailored to fit specific valve stem and housing dimensions. These sets are generally designed to comply with strict fugitive emission regulations, including ISO 15848-1, API 622, and EPA LDAR standards. The advantages of packing sets for fugitive emission control include:

- Precision and consistency – The pre-cut nature of packing sets guarantees uniform compression and mitigates the risk of incorrect installation, resulting in enhanced sealing performance.

- Compliance with standards – Numerous packing sets are engineered and tested to meet international fugitive emission standards, ensuring compliance with regulations.

- Enhanced sealing performance – These sets are crafted for optimal seating, which reduces leak paths and minimizes emissions.

- Reduced installation errors – The pre-cut design helps avoid over- or under-packing, which can cause excessive friction or insufficient sealing.

- Longer service life – Engineered packing sets often utilize high-purity graphite or hybrid materials that improve durability and decrease maintenance intervals.

- Easier and quicker installation.

Packing lengths

Packing lengths are available in continuous spools or coils, requiring manual cutting and installation. They provide flexibility for various applications and can be customised to fit different valve types.

The challenges of packing lengths in fugitive emission applications include:

- Inconsistent Installation – Manual cutting and packing may result in uneven compression, heightening the risk of emissions.

- Potential for gaps and leak paths – Improperly cut or installed packing can lead to leak paths, complicating the achievement of low fugitive emissions.

- Increased maintenance requirements –Packing lengths typically necessitate more regular adjustments and replacements because of uneven wear.

- Restricted compliance – If not installed and compressed correctly, packing lengths might have difficulty adhering to strict fugitive emission regulations.

Table 1 illustrates the differences discussed as well as additional ones.

Table 1. Advantages and disadvantages of packing lengths vs packing sets

| Criteria | Packing lengths | Packing sets |

| Flexibility | ✔ High – can be cut to fit many valve sizes | ✘ Low – each set fits a specific valve size |

| Inventory requirements | ✔ Lower – fewer sizes needed | ✘ Higher – many different sets required |

| Installation time | ✘ Slower – requires manual cutting && fitting | ✔ Faster – ready-to-use rings |

| Skill level needed | ✘ High – needs trainer personnel to install correctly | ✔ Lower – preformed rings reduce error |

| Sealing performance consistency | ✘ Variable – depends on installer | ✔ High – uniform factory-made rings |

| Cost per unit | ✔ Lower – bulk material is cost-effective | ✘ Higher – per-piece cost is greater |

| Critical valve suitability | ✘ Less suitable for high-risk valves | ✔ Preferred for emissions or high-pressure service |

| Turnaround efficiency | ✘ Slower for large critical jobs | ✔ Speeds up shutdown and revision work |

| Availability & lead time | ✔ Readilyy available in bulk | ✘ May need to wait for specific set deliveries |

Research Project

The Packings Division of the European Sealing Association initiated a research project aimed at evaluating the leakage performance of various packing lengths and sets in a laboratory setting.

The goal was to determine whether packing lengths can ensure a similar fugitive emission performance when properly installed as an emergency measure. Two widely used valve packings were examined on a packing test stand. The first was an expanded graphite packing reinforced with Inconel wire, typically utilised in high-temperature refinery valve applications. The second type of packing was a pure PTFE packing, primarily employed in chemical service.

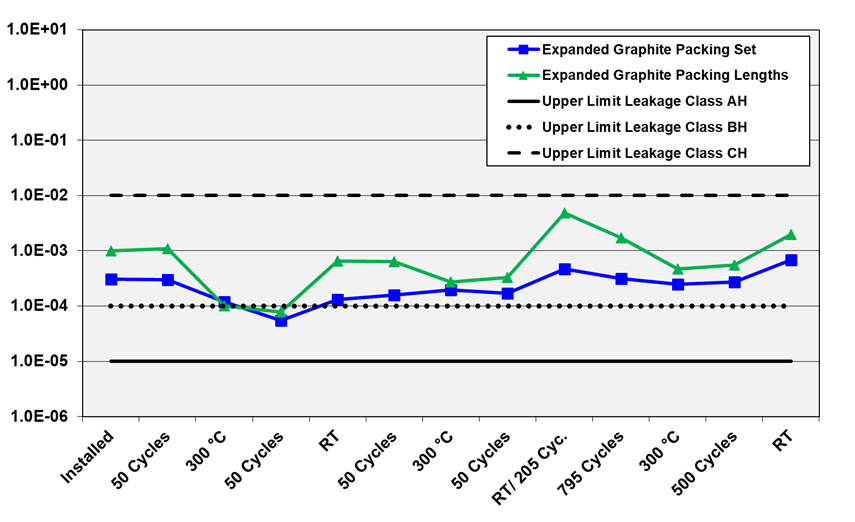

The graph depicted in Figure 1 illustrates the leakage performance of a packing length and packing set produced from identical expanded graphite material. The measurements were taken during an ISO 15848 CO2 test cycle using 40 bar helium. Both packing samples were subjected to the same initial gland pressure of 50 MPa.

The packing set demonstrates superior leakage performance overall; however, the packing length values are only slightly elevated and fall within the same leakage category CH. Figure 2 shows the leakage results for the PTFE packing.

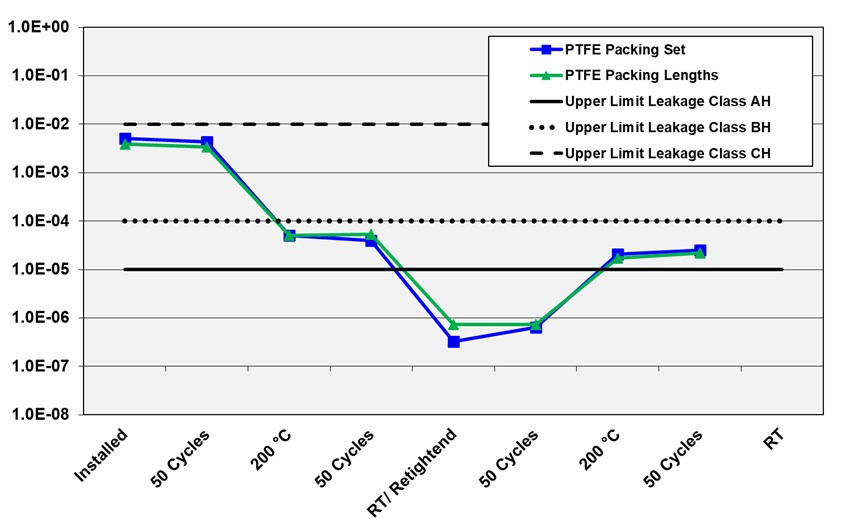

This test was conducted solely with a reduced CO1 cycle at 200 °C. The leakage performance of both samples is almost the same. Because of the significant temperature difference, the packings needed to be retightened after the initial cooling due to cold flow and gap extrusion, which is characteristic of PTFE packings.

Both tests conducted on these packing types revealed only minor variations in leakage performance when installed correctly. In the context of fugitive emission applications, valve packing sets offer considerable benefits in terms of regulatory compliance, sealing efficiency, and installation consistency. The testing indicated that packing lengths offer both flexibility and cost-effectiveness, achieving satisfactory emission performance when accurately cut and installed, particularly as an emergency solution during shutdowns when appropriately sized packing sets are not accessible.

About the author

About the author

Ralf Vogel is a mechanical engineer and has been working in the sealing industry for 30 years. Currently, he is the Technical Director of the European Sealing Association.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, August 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”

About the author

About the author