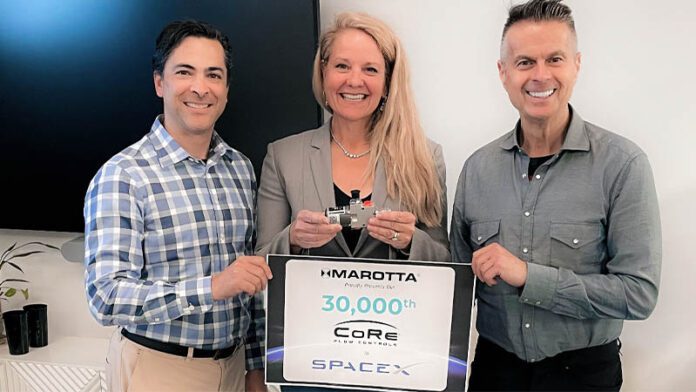

Marotta Controls, a rapidly growing aerospace and defense supplier with a 65-year-plus heritage in spaceflight, celebrated another production milestone recently. The supplier delivered its 30,000th CoRe® valve to SpaceX at its rocket development site in McGregor, Texas. The milestone marks a 50% increase in demand for the high-performance, reusable solenoid valves in less than 18 months, underscoring Marotta Controls’ deepening footprint in the spaceflight market.

The CoRe Flow Controls series includes 10 of the company’s most versatile solenoid valves capable of supporting various industrial flow control applications. These range from Attitude Control and Propellant Systems to Landing Leg Deployment and Stage Separation.

The CoRe series’ popularity is largely driven by its quality and flexibility along with product accessibility. The CoRe products stand as one of the only catalog valve portfolios for spaceflight. They are built with common, high-volume production components—an approach that allows for a cost-effective valve option with short production lead times.

CoRe valves are currently found in more than 10 vehicle platforms for customers launching more than 100 rockets per year, both domestically and internationally. They continue to be used in ground control and deep space applications, as well.

CoRe valves are designed for one- to three-quarter inch lines; handle fluids such as helium, methane, nitrogen, and oxygen; and are qualified to the Air Force Space Command’s (AFSC) SMC-S-016 standard for 10-flights. The latest models—the direct-acting MV100X and the pilot-operated MV524X—are designed for cryogenic temperatures.