Valmet will deliver a complete tissue line including a tissue making line and converting equipment to Suzano Papel e Celulose in Brazil. The order also includes a biomass boiler. This is Valmet’s first combined order with tissue making and tissue-converting lines after the acquisition of tissue converting business in late 2023. The tissue order also includes an extensive automation package, flow control valves, and Valmet Industrial Internet solutions.

The tissue making line and biomass boiler orders are included in Valmet’s orders received for the fourth quarter of 2023 and the tissue converting equipment order for the first quarter of 2024. The value of the total order will not be disclosed, but such an order is typically worth around EUR 100M.

The tissue making line, converting equipment, and biomass boiler will be installed at the Aracruz mill in Espírito Santo, Brazil. The target of the investment is to meet the Brazilian consumers’ increasing demand for high-quality tissue products with low environmental impact. The start-up is scheduled for the first quarter of 2026.

The new Valmet bubbling fluidized bed (BFB) boiler, which is scheduled to start operating in the last quarter of 2025, will use biomass to produce steam, which in turn is used in the cellulose process and in the generation of electrical energy.

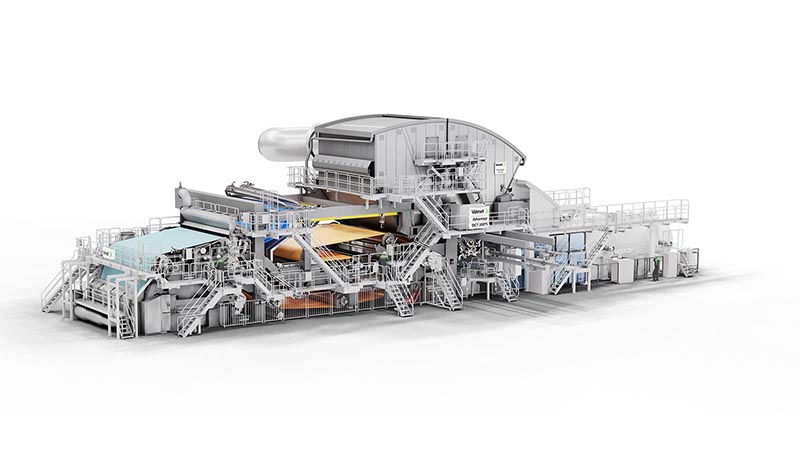

Valmet’s scope of supply comprises a complete tissue production line including Advantage DCT 200 tissue machine with OptiFlo headbox and Yankee cylinder. It will also be featured with the Advantage tissue technology including ViscoNip press, ReDry, AirCap hood with Air system, WetDust systems, and a SoftReel reel. Valmet will also deliver detailed mill engineering, stock preparation equipment as well as automation, including Valmet DNA Distributed Control System (DCS) with built-in machine condition monitoring, Valmet IQ Quality Control System (QCS), and Softness sensor.