To investigate the life prediction and the impact of ageing on elastomer seals, the Elastomeric & Polymeric Seals Division of the European Seal Association (ESA) initiated a new study in 2019.

By Benoît Omnès, Senior Expert in Sealing Technologies, Cetim

An earlier investigation by this team concluded that elastomer life prediction using tensile property ageing could be unreliable, so this new study was carried by a working group (James Walker, Kastas, Dupont, PPE and Cetim) on the effects of thermo-oxidative ageing on compression stress relaxation (CSR) and compression set (CS), which was suggested to be able to give more accurate life prediction data.

Experiments

The group carried out a series of accelerated ageing tests on a specific rubber material in their laboratories. The material, which was selected and supplied by PPE, was a fluoro elastomer (FKM) with a hardness equal to 75 Shore A. Two types of samples were manufactured: ISO 815-1 Type B buttons (6,3±0,3 mm thick and 13,0±0,5 mm diameter], and two sizes of O-ring to ISO 3601-1 (SC-214 and SC-329).

Ageing conditions

To apply accelerated ageing on the samples, three temperatures were selected (100, 150 and 200°C) for CS and the maximum temperature was limited to 180°C for the CSR jig. The six durations of the ageing phase were fixed to 24, 72, 168, 336, 672 and 1008 hours (42 days). The ageing was carried out in an oven equipped with thermocouples connected to continuous recorders.

Compression set

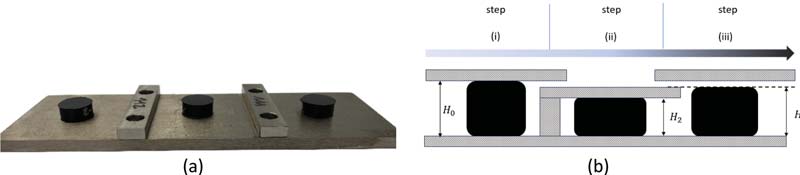

The first to be studied was the compression set (CS) in accordance with ISO 815-1. The test consisted of applying compression on the button and the O-ring (cut to avoid tightness) and to evaluate the elastic recovery of the rubber after disassembly (Figure 1a and b) at different temperatures and durations. Three samples are used to obtain an average and variance of measurement. The initial compression of 25% is applied using standard spacers. The relation is given by:

Here, H₀ is the initial value of thickness, H₁ the final value and H₂ the value of spacer.

Compression stress relaxation

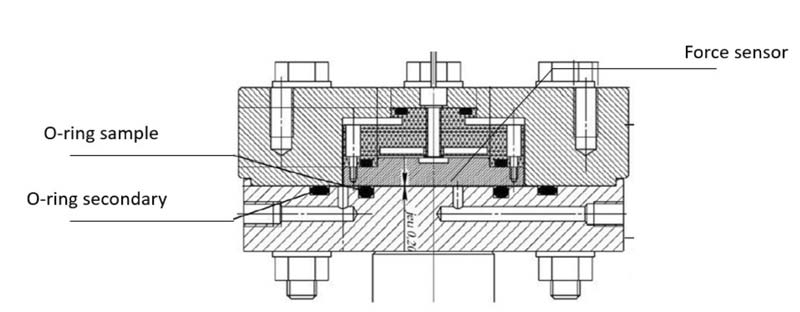

The second test apparatus (Figure 2) was developed by Cetim to measure the continuous change of the sealing force relaxation F(t,T) with time and temperature, using a force sensor to determine the compression stress relaxation (CSR). Once again, the level of compression is 25% on an SC-329 O-ring (50.17×5.33mm). The initial force F₀ is determined and the normalised force values (F/F₀) are investigated with time.

Analysis methodology

The change of CS and CSR depends on the time, the ageing temperature, and the size of the sample. To analyse and compare the values obtained by the working group, and to estimate the lifetime performance of the rubber, several steps were performed on the data as shown in Figure 3.

Modelling compression set and compression stress relaxation

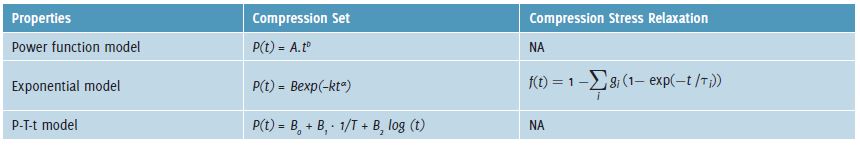

When you study the change of CS and CSR with time and temperature, it is possible to describe the value using different models to extrapolate for long-term prediction. A series of usual models is given in Table 1 for each property. For each configuration, a series of parameters are identified.

Arrhenius approach

Based on the ISO 11346 (Rubber, vulcanised or thermoplastic – estimation of lifetime and maximum temperature of use), the Arrhenius approach could be applied to the empirical model proposed in Table 1.

This approach is used when thermo-oxidative ageing appears in the material. The first step is to fix an end-of-life criterion corresponding to a limit of change of the properties studied. Often, the value of 50% is retained as end-life criterion as proposed in ISO 11346. However, it is possible to select the value of this criterion in relation to an operational function, for example leak-rate. Some authors evaluate the end-of-life criterion for CS at around 80-90% for O-ring. The Arrhenius approach assumes that a chemical damage is induced by the Here, A is the pre-exponential factor, Eₐ the Arrhenius activation energy, R the gas constant (8.314 J/mol-K) and T the absolute temperature.

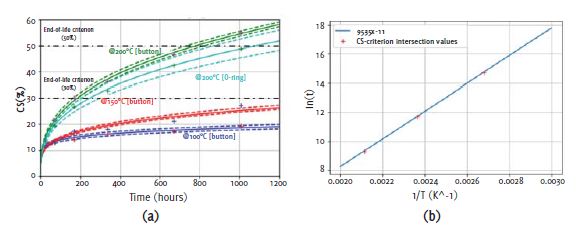

The activation energies are estimated from Figure 4a (for CS) Figure 4b for (CSR) transposed in Figure 4c. The slope of linear regression in ln(t) vs (1/T) allows calculation of Eₐ.

Results and discussions

Compression set

A complete study of the member’s compression set test data was carried out using the Arrhenius approach, using the end-of-life criteria at 30, 50 and 80%. Figure 5a shows an example of processing this data by Cetim using the ‘power law’ model, the use of which is necessary for extrapolation to the long term, particularly for an end-of-life criterion of 50 and 80% for CS. Figure 5b illustrates data processing according to Arrhenius to calculate the activation energy. We note the linearity of the data.

Table 2 gives the activation energy values obtained for the different members (A, B, C, D) for each of the end-of-life criterion values selected. A quasi-linear increase of the criterion is highlighted and a variability of the results according to the members for the same material. This observation can be explained by the ageing condition, which depends on the oven used, notably air renewal and air-circulating speed in the heating equipment.

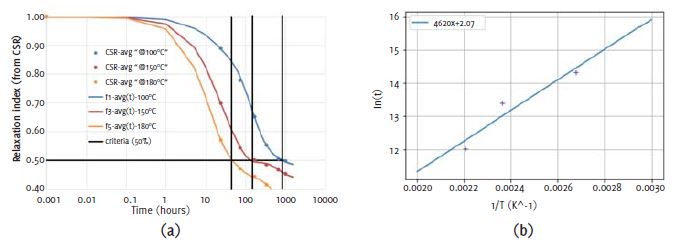

Compression stress relaxation

The analysis continued with a study of the change of CSR and the determination of the associated activation energy for a criterion of 50%. The series of tests was performed by 3 members of the WG and only one case could be treated in its entirety with an SC-329 O-ring (Figure 6a). The activation energy determined for CSR was 38 kJ/mol for the test duration studied (Figure 6b).

If we compare the activation energy between CS and CSR with the same end-of-life criterion of 50%, a difference was observed: Ea (CS) = 117 kJ/mol vs Ea(CSR) = 38 kJ/mol. This difference seems to be explained by the impact of ageing conditions and probably the size of the samples. The CSR apparatus developed by Cetim simulates a normal sealing system, which limits the amount of oxygen in contact with rubber in comparison with the CS apparatus.

Conclusions

The study carried out by the working group explored the accelerated ageing of an elastomer material and highlighted the impact of environmental conditions. The results were processed for the two properties (CS and CSR) to determine the activation energy using the Arrhenius approach. An assessment of the end-of-life criterion was explored, highlighting the impact and the risks of extrapolation to predict lifetime. Differences were found between the members and the properties, prompting further reflection.

The division continues to study the properties using the time-temperature superposition approach with Arrhenius and the possibility to implement into an FEA code to describe the permanent set observed. The differences highlighted encourage us to continue our discussions about the ageing of elastomers (impact of thermo-oxidation, linearity of Eₐ with 1/T, the functional criterion of tightness, etc.).

About the author

Benoît holds a PhD in Engineering Science, specialising in Material Mechanics. He has been a Senior Expert in Sealing Technologies at Cetim’s Fluid & Sealing Technology department since 2007. Benoît’s primary focus is on the modelling, FEA simulation, and experimental characterisation of elastomeric seals in static sealing systems. Additionally, since 2017, he has been responsible for coordinating R&D projects within the lab and partnerships.

Benoît holds a PhD in Engineering Science, specialising in Material Mechanics. He has been a Senior Expert in Sealing Technologies at Cetim’s Fluid & Sealing Technology department since 2007. Benoît’s primary focus is on the modelling, FEA simulation, and experimental characterisation of elastomeric seals in static sealing systems. Additionally, since 2017, he has been responsible for coordinating R&D projects within the lab and partnerships.