Utmost Alloy is a high-end precision metal + metallurgy technology enterprise integrating R&D, production, sales and service. We are a leading manufacturer of high-precision, high-complexity and mission-critical casting and machined components for global diverse end-markets.

With a production site of 25,000 square meters, 300+ employees and 7500+ tons capacity per year. We are a foundry with global market which produces investment castings, sand castings, offers squeeze casting, precise machining, 3D printing, computer simulation and detection analysis, surface treatment, assembling services and casting-related solutions. We contribute to the development of the global industry by providing high quality castings, machined parts and professional casting engineering solutions to the petrochemical, marine, food & pharmaceutical, energy & power and aviation industries.

Building a people-oriented, science and technology-based innovative, customer’s pain point focused enterprise.

We use 3D printing, casting simulation and ceramic core to develop new products efficiently, science and technology enables complicated products to be implemented, it improves quality and efficiency, and achieve lightweight engineering at the same time. We use advanced science and technology to optimize production technology and alleviate labour intensity, trying our best to produce products in line with customer market demand efficiently. Our efforts gained customer’s favour, and their favour give us the power to move forward.

We are committed to building an environmental protection enterprise – the steel itself is recycled, wax reclamation, sand reclamation system and so on. Also, we are a class A foundry with strict requirement for environmental protection, all exhaust emissions should be collected in closed room to achieve environmental protection level 3 capture, fresh air + constant temperature, make sure the sand does not fall to the ground, gas does not escape.

Foundry

Method Investment + Sand

Annual Output 7,500Ton

Product weight Unit Wgt.: </=1,500kg

Surface Roughness Inv’ Ra1.6-6.3

Sand Ra25-50

Main Equipments WMS-AGV-WCS,Moulding Automatic Line, Auto Pouring,Wax Injection,Wax Recycling System, Automated Shell Line, Shot Blasting Equipment, Automated Pickling Line, Sand Reclamation System, Inspection Equipments…

Main Materials

Austenitic & Martensitic Stainless Steels

ASTM CF8M(316), CF3M(316L), CF8(304), CF3(304L), CA6NM, 17-4PH

DIN-EN 1.4408, 1.4409, 1.4581, 1.4308

BS 316C16, ANC4B, 316C12, 304C15

JIS SCS14, SCS16, SCS13

Duplex Steel

ASTM 4A(CD3MN), 5A(CE3MN), 6A(CD3MWCuN)

DIN-EN 1.4470, 1.4410,1.4469,1.4517

BS ANC21

JIS SCS10

Carbon Steel

ASTM WCB, WCC, WC6,WC9,LCC

DIN-EN 1.0619, 1.7357, 1.7131

MACHINE SHOP

Range Diameter 2100 * 1500

Main Equipments: Automatic Truss Production Line

Automation Flexible Production Line – 800*1700

Vertical machining centers – 1300*570

CNC Lathe – 1000*2000

vertical Lathe – Φ2000*1400

Inspection Equipments: CMM Inspection

Hydro/Air Pressure Test,

Dynamic Balancing

Industries Served

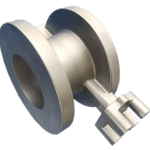

Product Type: Valves, Pumps, Mechanical Components

Related Industries: Oil,Gas&Chemical, Marine & Offshore, Food and Pharmaceutical, Aerospace, Energy & Power, Automobile

CERTIFICATES AND QUALIFICATION

ISO9001:2015

IATF16949:2016

PED 2014/68/EU & AD 2000-Merkblatt-W0

Marines Society Approval

Foundry:

UTMOST ALLOY (Shandong) Co., Ltd.

Foundry: #1, Futang Road, Beisu, Zoucheng, Jining, Shandong, P.R.C.

Tel: 0537 – 5181885

Sales Center:

Room 408, Hongqiao Ali Center, Shenchang Road, Minhang District, Shanghai, P.R.C.

Email:enquiry@utmost-alloy.com

Mobile:137 5118 5621

Web:www.utmost-alloy.com