This article follows [

Part 1] of a series by Mr Neeraj Batra from Chiyoda Corporation.

Definition: There is no definition of tight shut off (TSO) with respect to valves in API 6D or ASME B16.34 and this is where the confusion arises. Vendors often claim that the valves offered are tight shut off without commenting on the leakage rates or the type of test conducted (low pressure or high pressure) or the testing medium(air or gas).

Vendors try to introduce more confusion when they mention leakage class I to VI of ANSI/FCI-70-02: Control valve seat leakage for the manual valves. Although it is possible that the vendor can achieve a tightness class V or VI we still need to know the pressure at which the valve was tested and the testing medium, be it air and water or inert gas like helium.

Purpose: As explained above in the section on plant isolation philosophy, the tightness level required during the isolation activity depends on the fluid to be isolated. Isolation for hazardous fluid like H2S, HCl, and sulphuric acid has a direct impact on human beings, isolation of flammable services has consideration for fire whereas the isolation of utility services like air or water only has a potential impact in terms of fluid loss and hence the acceptable leakage rate levels will vary.

What the process and valve specification engineer can do: The purpose of this article is not to explain what leakage rates shall be specified for the different fluid services but rather to highlight that different leakage class and different pressure testing methods are based on the testing standard selected. So, the requirement of leakage class shall be checked in an end user’s isolation philosophy and if the vague term-TSO exists then the definition of TSO shall be specified in the updated Isolation philosophy. The definition is complete when the following two terms are clearly specified:

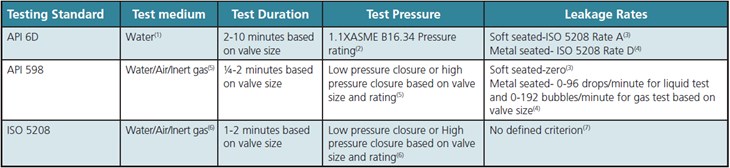

a) Testing standard for the valves and applicable leakage rates. The following three standards are widely used for testing the valves:

API6D: Specification for pipeline and piping valves

API 598: Valve inspection and testing

ISO 5208: Industrial valves – pressure testing of metallic valves

b) Test details-What will be the test medium and required leakage rates if not clearly specified in the test standards.

Table 1 is an attempt to summarize the requirements in the above-mentioned standards but in no case should this data be considered as a substitute to the above standards.

Notes:

1. High pressure gas seat testing option is available as per Annex-H/Supplementary test requirements. Gas testing should be considered for high pressure pipeline valves or valves carrying flammable services like LNG. Leakage rates for gas testing shall be discussed with vendor.

2. Reduced test pressure=1.1x design pressure can be used for valve testing after agreement with the end user to reduce the valve cost.

3. There are disagreements among the high performance butterfly valve suppliers about the classification of laminated seal ring as soft seat or metal seat. End users, EPC contractors and valve users should have an aligned understanding. (See Figure 3.)

4. Some metal seated valves like torque seated expanding gate valve, fine machined/lapped ball valves or lubricated pressure balanced plug valves can meet the requirements of leakage rates for soft seated valves.

5. Refer to API 598 /Table-1&2 for applicable pressure test. A low pressure closure test means that seats will be tested with air or inert gas at 4-7 Barg of pressure whereas high pressure closure means that seats will be tested with air, inert gas or liquid at 1.1x pressure rating of the valve.

6. Refer to API ISO 5208/Table-1 for applicable pressure test. A low pressure closure test means that seats will be tested with air or gas with 4-7 Barg of pressure whereas high pressure closure means that seats will be tested with liquid at 1.1x pressure rating of the valve.

7. The valve specification engineer has the responsibility to define the required leakage rates. Generally valve vendors can achieve leakage rates A/AA for

soft seated valves and leakage rated D for metal seated valves. Table-4 of ISO 5208 should be referred to for available leakage rates.

Unidirectional / bidirectional

Definition: There is clear definition in API 6D about unidirectional and bidirectional valves, the testing method for these valves and finally the marking method. However, API 6D does it best to confuse its readers by introducing more details such as block and bleed, double block and bleed, double isolation and bleed etc. We will discuss about DBB/DIB in next section.

The following definitions are taken from API 6D:

• bidirectional seat: Valve seat designed to seal against pressure source in either direction.

• bidirectional valve: Valve designed for blocking the fluid in both downstream and upstream directions.

• unidirectional seat: Valve seat designed to seal the pressure source in one direction only.

• unidirectional valve: Valve designed for blocking the flow in one direction only.

ASME B16.34 gives very less or rather no information about unidirectional or bidirectional valves.

Purpose: Often the end user engineer requires all valves to be bidirectional without understanding the real rational for

a bidirectional valve. This results in the EPC contractor buying costly bidirectional valves whereas in actual fact a unidirectional valve would serve the required purpose.

When are bidirectional valves required?

• Process requirements: Some process services will require a bidirectional valve. However, for isolation valves where a maintenance activity is required downstream of the valve, a unidirectional valve is sufficient. So, specifying “All Isolation valves shall be bi-directional” shows a lack of engineering judgement on the part of the end user or the EPC contractor.

• Installation constraints: Some end users have apprehensions that if the unidirectional valve is installed in the wrong direction then the whole purpose of the isolation valve will not be achieved when a maintenance activity is required.

• Required tightness in isolation direction: Some valves like triple offset butterfly valves and eccentric ball valves have a favorable direction of sealing based on their mechanical construction. If the valve is not installed in the right direction then the required tightness class cannot be achieved.

What the process and valve specification engineer can do:

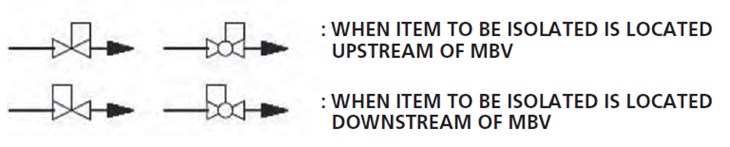

First, the most important thing is to understand the basic functioning of the valve and its impact on the unidirectional bidirectional isolation feature. For requirement 1 discussed above, only a bidirectional valve shall be selected but for requirement 2 and 3 a proper indication is required on the P&ID, piping isometric, 3D model and physically on the valve itself such that valve is installed correctly. (See Figure 4). Appendix 1 summarizes the basic features of the most commonly used isolation valves.

Appendix 1 will be included in Part 3.