This aim fits the rich heritage of Neles, a well-known brand that has been around for decades. In the summer of 2020, Neles – formerly known as Metso Flow Control – spun out of Metso and became an independent company with a 100 per cent focus on valves.

When asked about R&D/product development, Mr. Isotalo said Neles will expand and improve its product gamma. “Also, we are exploring new manufacturing methods, material science, and materials technologies, e.g. 3D-printing.

There are also programs going on to improve our simulation and design automation capabilities.”

Reliability key

Mr. Isotalo mentioned material science. Jussi Hellman, Manager of Materials Engineering, is an expert in this field. Initially, he started his career in science, heading a group of scientists at Aalto University that was researching wear resistant materials for various applications (mining, etc.). Since 2002, he has been working for multiple departments within Metso, eventually moving to Metso Flow Control, now Neles.

“Reliability is very much a call for material science”. Mr. Hellman says. “Needless to say, safety comes first, but the next important feature of an industrial flow control solution is reliability. This parameter allows for an uninterrupted production without malfunctions or failures.”

More times than often, material wear is the root cause of these failures, which leads to unplanned downtimes and production loss.

Additionally, these failures have additional drawbacks, such as material and energy con sumption (production and transport of spare parts, ed.) that could have been avoided.

Furthermore, the poor performance of flow control equipment often means an increase in fugitive emissions and increased occupational health hazards during production and maintenance, especially if predictive planning and preparation are not possible.

Metal matrix composites

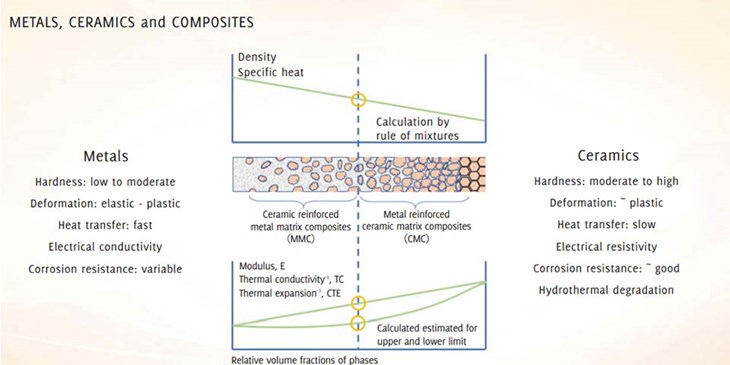

Ceramic materials traditionally play a crucial role in wear protection, Mr. Hellman states. “Various ceramic materials have long been used as a protective lining inside valves, and in many challenging wear applications, ceramic valves offer the best performance available. However, monolithic ceramics have their inherent limitations, such as hydrothermal degradation, limited resistance to thermal shocks, and lack of electrical conductivity.

Metal matrix composite materials (MMC) bundle the superior hardness of ceramics and the toughness of metals to offer the best possible reliability and performance to end-users.

In MMC, the ceramic addition is embedded into metal, and contributes especially the wear resistance, while the metal carries the mechanical load and improves impact resistance.

Challenging

Neles has expertise in technologies, such as advanced powder metallurgy which are needed to integrate metal matrix composite (MMC) materials into products. These MMC’s are then used as an inner layer in multi-material constructions where the outer layer is a standardized construction material. This combination is necessary because valves are pressure equipment, and pressure retaining parts must be ductile to meet PED-requirements.

“One typical challenge for the engineering process is that both metals and MMC’s react differently in terms of thermal expansion”, Mr. Hellman says. “This phenomenon can lead to too high internal stresses unless the materials are care fully matched. We have developed several MMC-grades that have been optimized both for manufacturing and operational functionalities.”

Common issue

Coming back to the subject of wear and corrosion, Mr. Hellman says that it is a common issue in various industry sectors.

“Although the products from pulp and paper- or oil and gas industry are very different from those of mining and metal refining industries, production facilities struggle with similar challenges in finding efficient protection against severe wear and corrosion.”

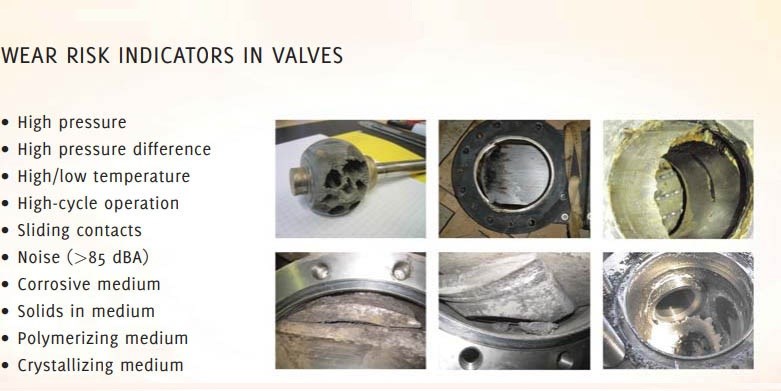

According to Mr. Hellman, it is crucial to detect early signs of wear in valves to address this issue pro-actively.

And, in terms of process conditions, there are several good risk indicators: high-pressure temperatures cycling (fluctuations), high-cycle operation, sliding contacts, or high noise. Needless to say, the wear issues are more likely to arise in the case of corrosive media, solids in media, or when polymerization or crystallization occurs in the medium.

Jussi Hellman is manager Materials Engineering at Neles.

Jussi Hellman is manager Materials Engineering at Neles.