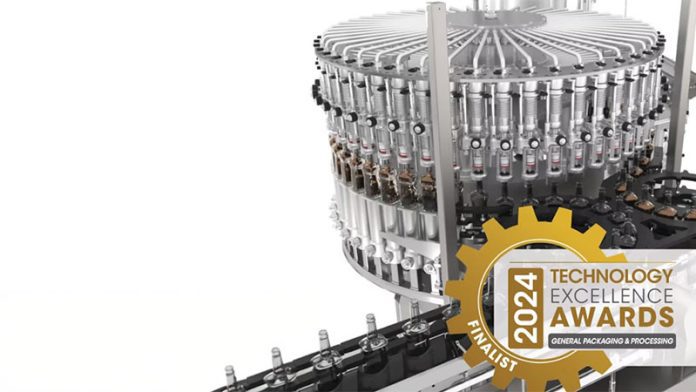

Fogg Filler, a ProMach product brand and market leader in the design and manufacture of rotary filling systems for the beverage industry, is excited to showcase the new PF 1800 model from its new PF Series pressure filling systems at Pack Expo International, at McCormick Place, in Chicago, IL.

Engineered as a hybrid system, the PF series delivers unparalleled performance advantages over traditional gravity bowl and pressure filling designs. At the heart of this innovation is a technological pairing that integrates the precision and product supply pressure of contactless electronic metering valves with the closed-loop bypass process controls of traditional contact filling valves. The result is a more efficient, cleaner, and faster filling process, especially for distilled spirits and hot fill beverage applications.

The PF Pressure Filler’s innovative valve designs and “predictive pumping” technology enable faster and more efficient filling for a wide range of food and beverage products. Fogg’s precision control over product supply and venting systems reduces foam formation, ensures consistent fill weights, and creates a cleaner filling environment. For the spirits industry, this technology ensures proof integrity, while for hot-filled products, it maintains exact temperature control through the entire valve body, even during line stops, resulting in precise temperature management.

The PF Series pressure filler is a finalist for PMMI’s Technology Excellence Awards in the General Packaging and Processing category.