Greene Tweed, a global manufacturer of high-performance sealing solutions and engineered components, announces the introduction of Fusion® F07, a performance-enhanced fluoroelastomer. Developed by Greene Tweed material scientists and application engineers, Fusion® F07 is specifically crafted to withstand common Etch and CVD oxygen/fluorine based gases in semiconductor processing subfab lines, at temperatures up to 355°F (180°C).

With an expected lifetime of at least 6 months, Fusion® F07 lasts longer than standard FKM in subfab vacuum system lines. As a result, the new performance enhanced FKM extends the time between planned maintenance activities. Notably, it provides a better total cost of ownership where applications do not require an FFKM compound.

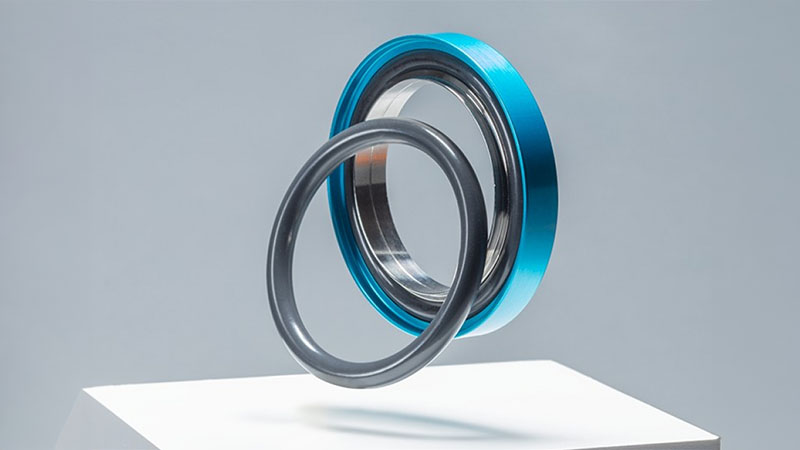

Fusion® F07 can be purchased as a seal assembly or as an individual O-Ring. Customers can effortlessly upgrade to Fusion® F07 and experience the benefits of an extended lifetime and the resultant reduced operating costs as the seals are form-fit replaceable with other industry standard (KF/ISO flange fittings) seals. A blue outer ring allows for easier identification upon installation and replacement. Fusion® F07 seals are available in most typical sizes, including KF16, KF25, KF40, KF50, ISO63, ISO80, ISO100, ISO160, and ISO200.

As a global provider of sealing solutions to the semiconductor industry for over four decades, Greene Tweed engineers advanced elastomer seals and thermoplastic components that are found in a broad range of mission-critical equipment in key process areas of the world’s semiconductor fabs, including etch, deposition, aqueous, and electro-chemical (electroplating). The company is now investing in Korea with its upcoming state-of-the-art manufacturing facility expected to commence production this year.