Self-cleaning metamorphic trim products stand to alleviate expensive control valve failures caused by erosion from processing debris-laden products, says an industry expert. The gas processing sector is losing significant sums annually to valve reliability issues in harsh environments. The introduction of self-cleaning components combining multi-stage labyrinth and cascade technology could prove a game-changer in terms of plant safety, productivity, and profitability, says Karl Wonisch, Head of Europe Control Valves at IMI Critical Engineering.

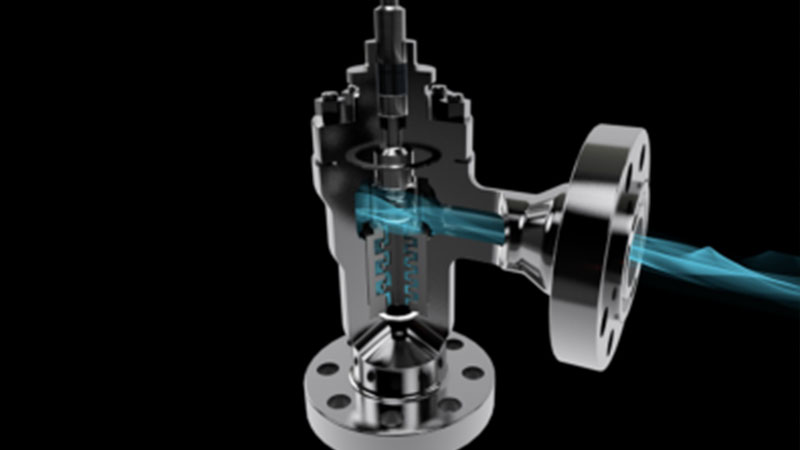

IMI Critical Engineering has developed EroSolve Metamorphic Trim (MMT), which uses a unique self-cleaning design and velocity control methodology throughout the whole fluid passage, reducing the risk of damage and clogging. The trim, which is custom-designed to fit existing valve bodies and actuators, also benefits from the gradually divided pressure drops associated with cascade-style solutions, as well as reduced installation costs.

The effectiveness of the EroSolve MMT has already been demonstrated following its installation downstream of the glycol dehydration contactor of a multinational oil and gas producer in the North Sea. With the application proving challenging due to high-pressure drops, very low flow, solid particles, and sludges in the fluid, the material was regularly collecting at the bottom of the contactor, impeding passage through the control valve.

Combined with the occurrence of slugs following a trip of the gas compression system, the valve needed cleaning on a regular basis. This resulted in unplanned downtime and annual production losses totalling GBP 2M. However, by implementing the EroSolve MMT, the high pressure drops, and small flow rates previously hampering performance could be mitigated.