Parker Hannifin, the global leader in motion and control technologies, is introducing a new safety block (SB series) for hydraulic accumulators that simplifies the selection, installation, and maintenance process of these important system components. Due to the broad variety of accumulator types and their applications, the market is proliferated with an equally wide expanse of safety blocks that, until now, have made selection challenging for many customers. Developed by the company’s Cylinder and Accumulator Division Europe (CADE), the new safety block overcomes this time-consuming issue.

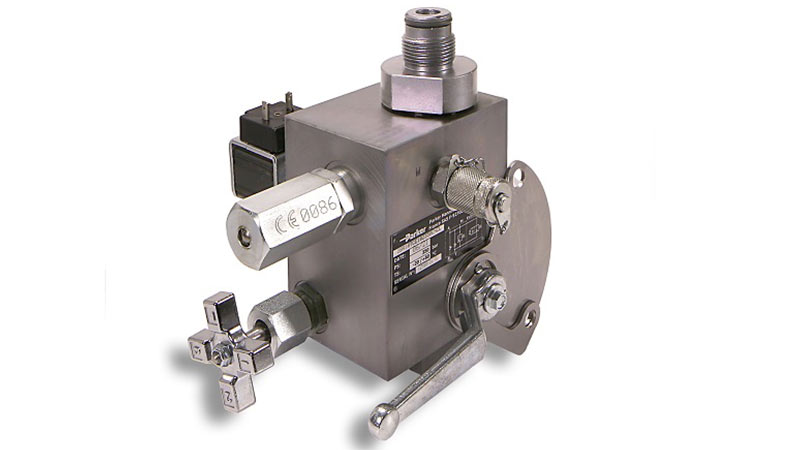

Safety blocks enable hydraulic accumulators to be isolated for maintenance work, repairs, or system tests, acting as an emergency shut-off device to protect against system failure. Based on the ethos that simple engineering makes for a safer solution, the versatile SB series offers full functionality in a single product: isolation, drain, peak pressure protection, and pressure control. As a result, choosing the right safety block is now far easier – regardless of the application. Typical markets set to benefit from the new concept include industrial, mobile, oil, and gas to list but a few.

Offering an improved design that helps to minimise space requirements and to ease installation, the SB series is available in sizes 10, 20, and 32. Users can enjoy advantages such as a standardised temperature range of -20°C to 80°C, and high corrosion resistance compliant with ISO 9227. In addition, the SB series is PED-certified and suitable for use in ATEX environments (manual version only).